Automatic multifunctional wall painting machine and application

A multi-functional, painting machine technology, applied in the direction of architecture, building construction, etc., can solve the problems of time-consuming and laborious, unguaranteed, poor painting personnel, etc., to achieve the effect of ensuring the beautification of the environment and the quality of painting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

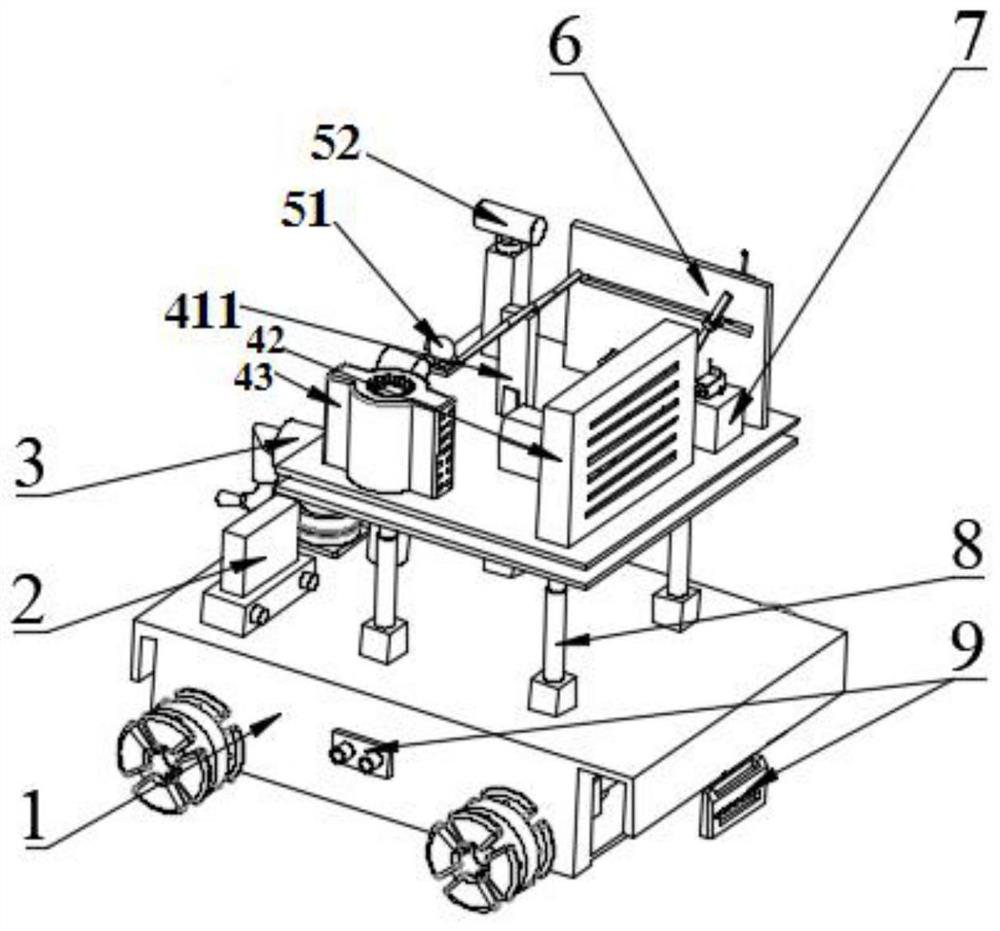

[0084] An automatic multi-function wall painting machine, such as Figure 1-16 As shown, it includes a mobile device 1, a lifting device 8, a working platform, and a feeding device 7 and a painting device 6 positioned on the working platform;

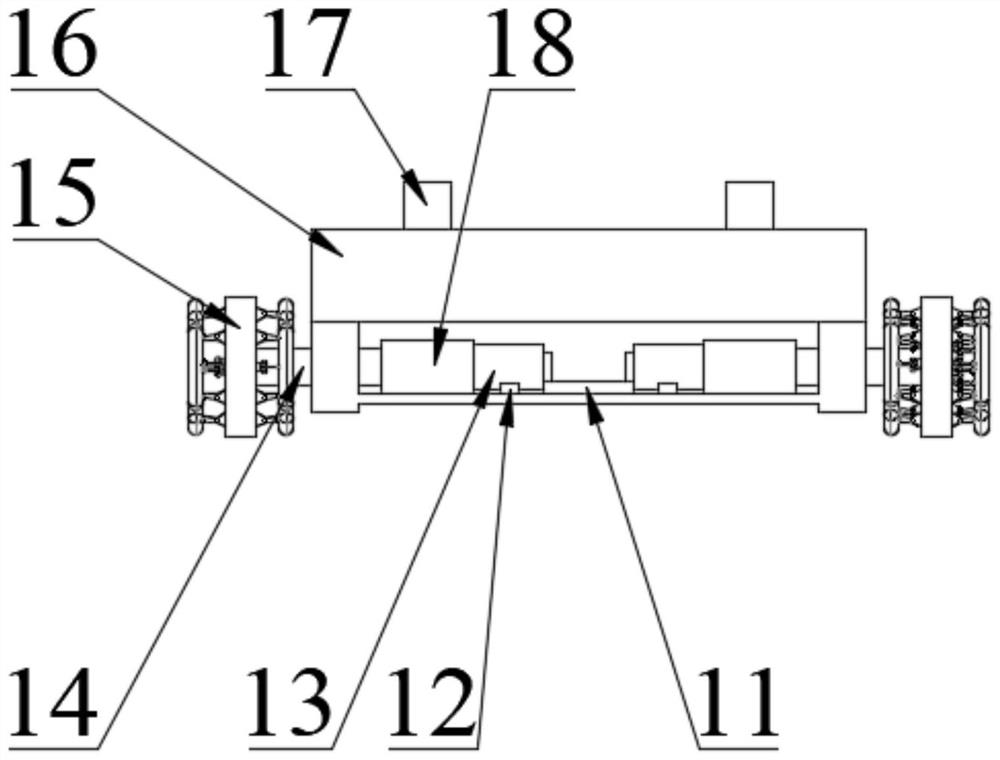

[0085] Such as figure 2 As shown, the mobile device 1 includes a vehicle body 16, four wheels 15 are arranged on both sides of the vehicle body 16, a controller 11 is arranged in the vehicle body 16, and the controller 11 is connected with four DC motors 13, and four DC The transmission shaft 14 of the motor is respectively connected to four wheels for driving the rotation of the wheels;

[0086] The working platform comprises a main platform 85 and an auxiliary platform 84. The feeding device 7 and the painting device 6 are located on the main platform 85. A lifting device 8 is arranged between the vehicle body 16 and the auxiliary platform 84. The auxiliary platform 84 can be up and down relative to the vehicle body 16. Movement, t...

Embodiment 2

[0089] An automatic multifunctional wall painting machine, as described in Embodiment 1, the difference is that the controller 11 and the DC motor 13 are all arranged in the body of the car body, and the controller 11 is fixed in the card slot inside the car body, and the car body Also be provided with motor support 12 and speed reducer 18 in 16, DC motor 13 is fixed on vehicle body 16 inside by motor support 12, and each DC motor 13 is connected wheel 15 by speed reducer 18, transmission shaft 14.

Embodiment 3

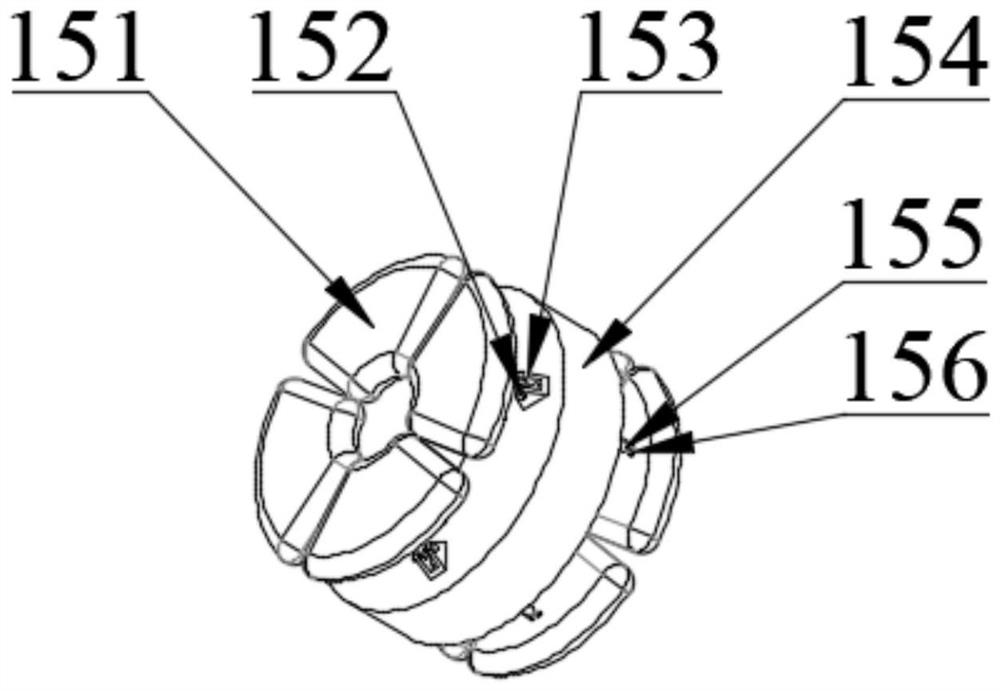

[0091] An automatic multifunctional wall painting machine, as described in Embodiment 2, the difference is, as Figure 3-5 As shown, the wheel 15 includes a driving middle wheel 154, and the transmission shaft 14 is directly connected with the driving middle wheel 154. The inner and outer sides of the driving middle wheel 154 are respectively provided with an obstacle-breaking wheel set A and an obstacle-breaking wheel set B. The obstacle-breaking wheel set A and the obstacle-breaking wheel set The obstacle-crossing wheel set B all includes four wheel blades 151, wherein, the driving middle wheel 154 is evenly provided with four pairs of first Connecting seat 153, the number of every pair of first connecting seat is two, and all distributes along the radial direction, all is screwed with 2 second connecting seats 156 on each wheel leaf, every 2 second connecting seats 156 and wherein A wheel crank 155 is connected by a turning pin 152 between a pair of first connecting seats 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com