Intelligent paint spraying robot system

A robot system and robot technology, applied in the direction of instruments, manipulators, injection devices, etc., can solve the problems of being unsuitable for the automobile maintenance industry, the health hazards of operators, and low efficiency, so as to improve the overall service level, reduce labor intensity, and reduce production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

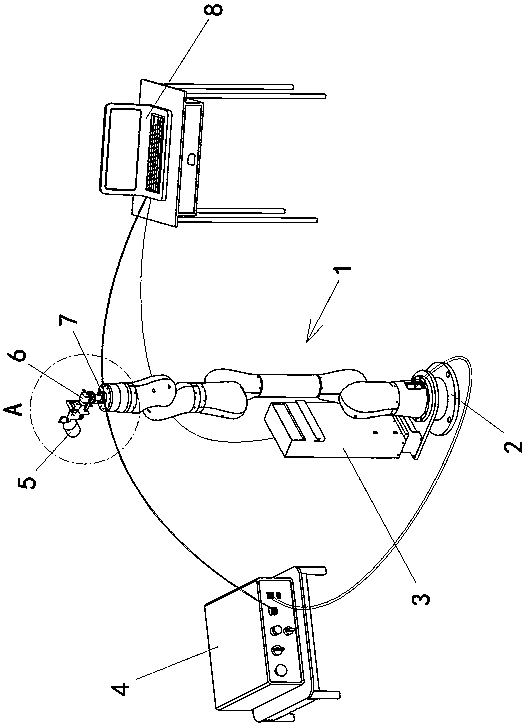

[0012] Such as figure 1 , 2 Shown: the intelligent painting robot system of the present invention includes a robot 1, and the robot 1 is a fifth-generation modular robot. A base 2 is provided at the lower end of the robot 1, and the robot 1 is fixedly installed on the foundation through the base 2 and anchor bolts during installation.

[0013] The robot 1 is connected to the controller 4 , the controller 4 is connected to the processor 8 , and the external processor 8 is connected to the depth camera 3 .

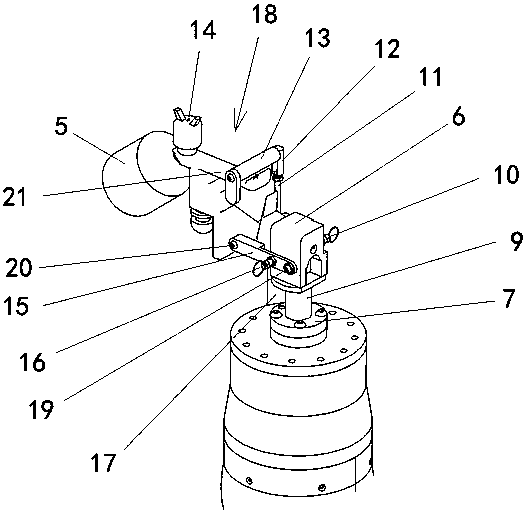

[0014] The upper end of the robot 1 is connected to one end of the connecting shaft 9 through the flange 7 , and the other end of the connecting shaft 9 is fixedly connected with the mounting seat 6 .

[0015] The installation shaft of the paint spraying device 18 connected with the paint storage cylinder 5 is inserted into the long hole arranged in the up and down direction inside the mounting seat 6, and a first positioning bolt 10 for positioning the mounting shaft of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com