Technique of manufacturing steel spade in environment protechion type

A production process and section steel technology, which is applied in the production process field of environmentally friendly steel shovels, can solve the problems of washing waste water discharge polluting the environment, unable to guarantee product quality, and difficult to operate, etc. The effect of complete transformation and improved working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

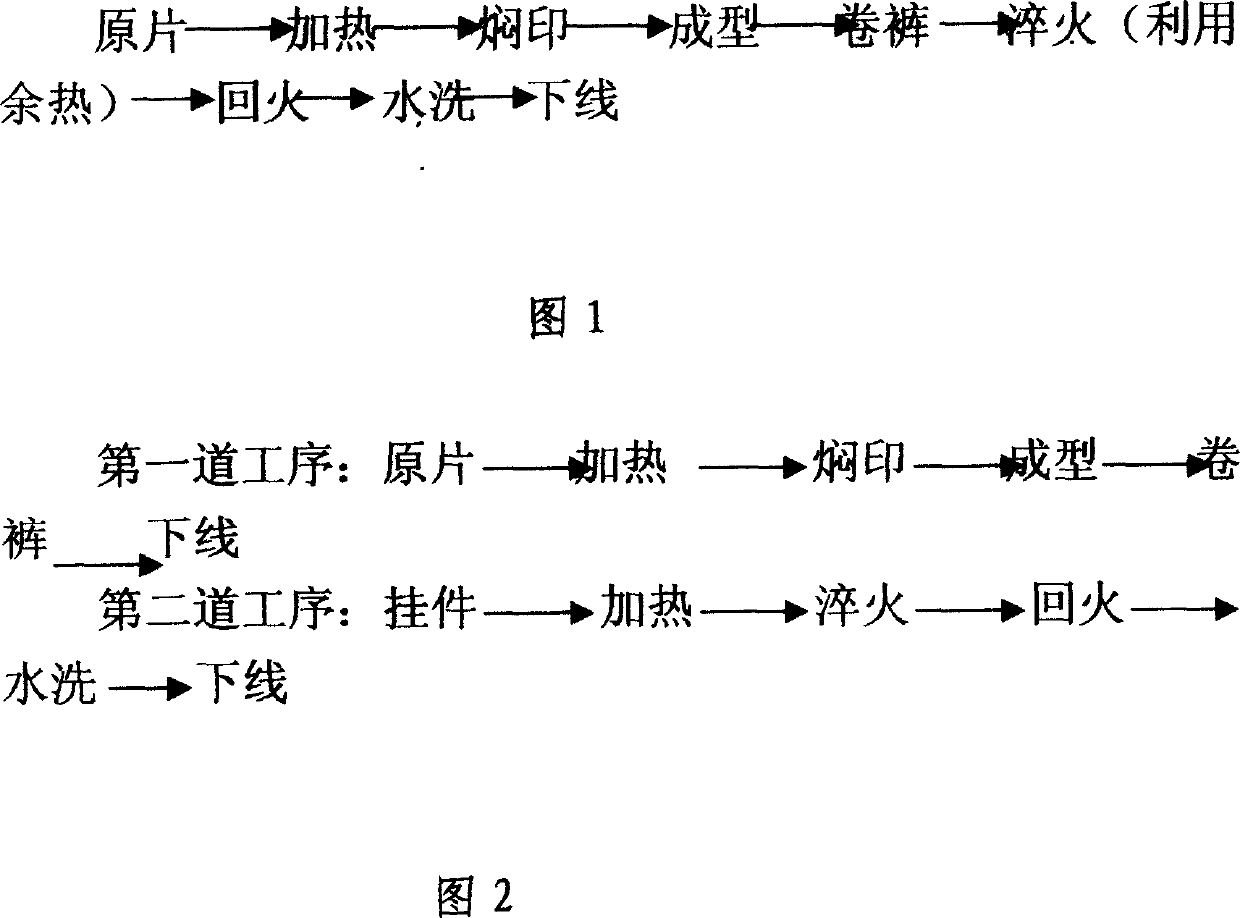

[0018] The present invention is an improvement to the prior art, and the existing two production lines are changed into one production line, and the equipment used includes a roller hearth furnace, a mechanical press, heat treatment equipment (tempering furnace, etc.) and a water washing device. A quenching medium recovery device is installed on the side of the roller hearth furnace, and the washing water of the washing device is connected to the quenching medium recovery device with a recovery pipe. This technique uses liquefied gas after electricity as heating source, and the present invention adopts liquefied gas to heat, and its technological process is as accompanying drawing 1, referring to accompanying drawing 1, the present invention operates production by following steps:

[0019] 1. Put the raw shovel into the roller hearth furnace, and heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com