Technology of manufacturing steel spade

A production method and a steel shovel technology, applied in the direction of hand tools, etc., can solve the problems of washing waste water discharge to pollute the environment, unable to guarantee product quality, difficult operation, etc., to avoid heat loss, complete transformation of metallographic structure, and improve the working environment. Effect

Inactive Publication Date: 2005-07-27

付长智

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

During the heating process of heat treatment, the deformation of the workpiece is serious, and manual shaping is required to restore the shape, which not only wastes manpower, but also cannot guarantee product quality due to the difficulty of operation

Moreover, there is no recovery process of quenching medium in the production process, and the washing wastewater is directly discharged to pollute the environment

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

An environmental protection type technology for manufacturing the steel spade includes heating the raw steel plate in roller furnace, die pressing by mechanical press, rolling its tubular part by a rolling machine, quenching in hardening medium, tempering in tempering furnace, washing in water washing apparatus, heating the sewage by the afterheat of roller furnace for evaporating and concentrating, and recovering the hardening medium. Its advantages are high quality of product, no environmental pollution.

Description

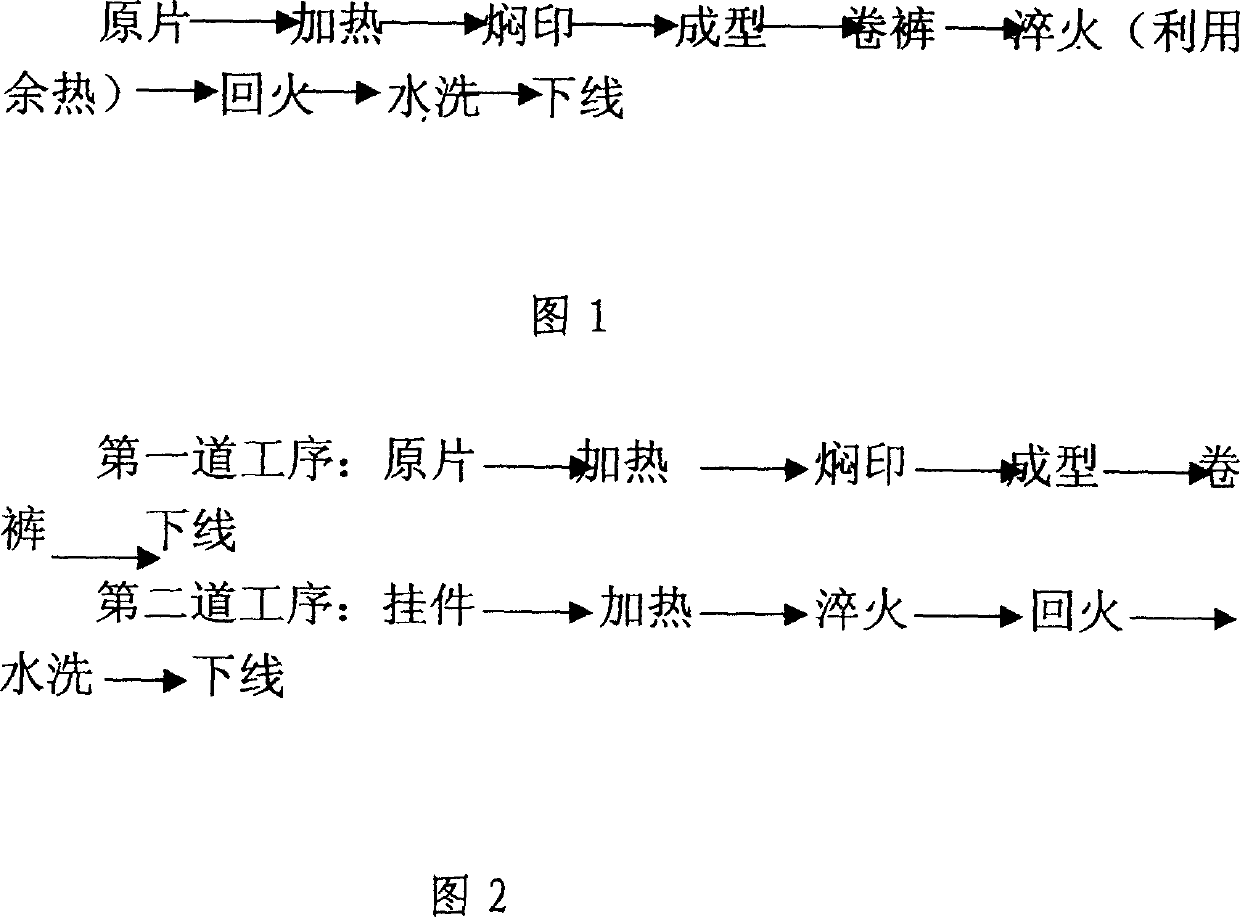

technical field The invention relates to a production method of a steel shovel, which belongs to the technical field of agricultural machinery manufacturing. Background technique At present, the production of steel shovels uses coal as the heating source, and the emission concentration of smoke and dust is high, which seriously pollutes the environment. In the production process, the heating temperature is controlled by manual visual inspection, and the temperature fluctuates greatly, which cannot guarantee the hardness of the workpiece well. The existing production process flow is shown in Figure 2. It has two processes of forming and heat treatment, and each process needs to heat the workpiece. During the heat treatment heating process, the deformation of the workpiece is serious, and manual shaping is required to restore the shape, which not only wastes manpower, but also cannot guarantee product quality due to the difficulty of operation. Moreover, there is no recove...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): A01B1/00

Inventor 付长智

Owner 付长智

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com