Wall surface rolling brushing type coating device

A rolling brush and paint technology, which is applied in the direction of construction and building construction, can solve the problems of difficult cleaning, single function of the wall roller, and paint splashing, so as to reduce splashing and dripping and ensure painting The effect of quality, convenient and quick disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

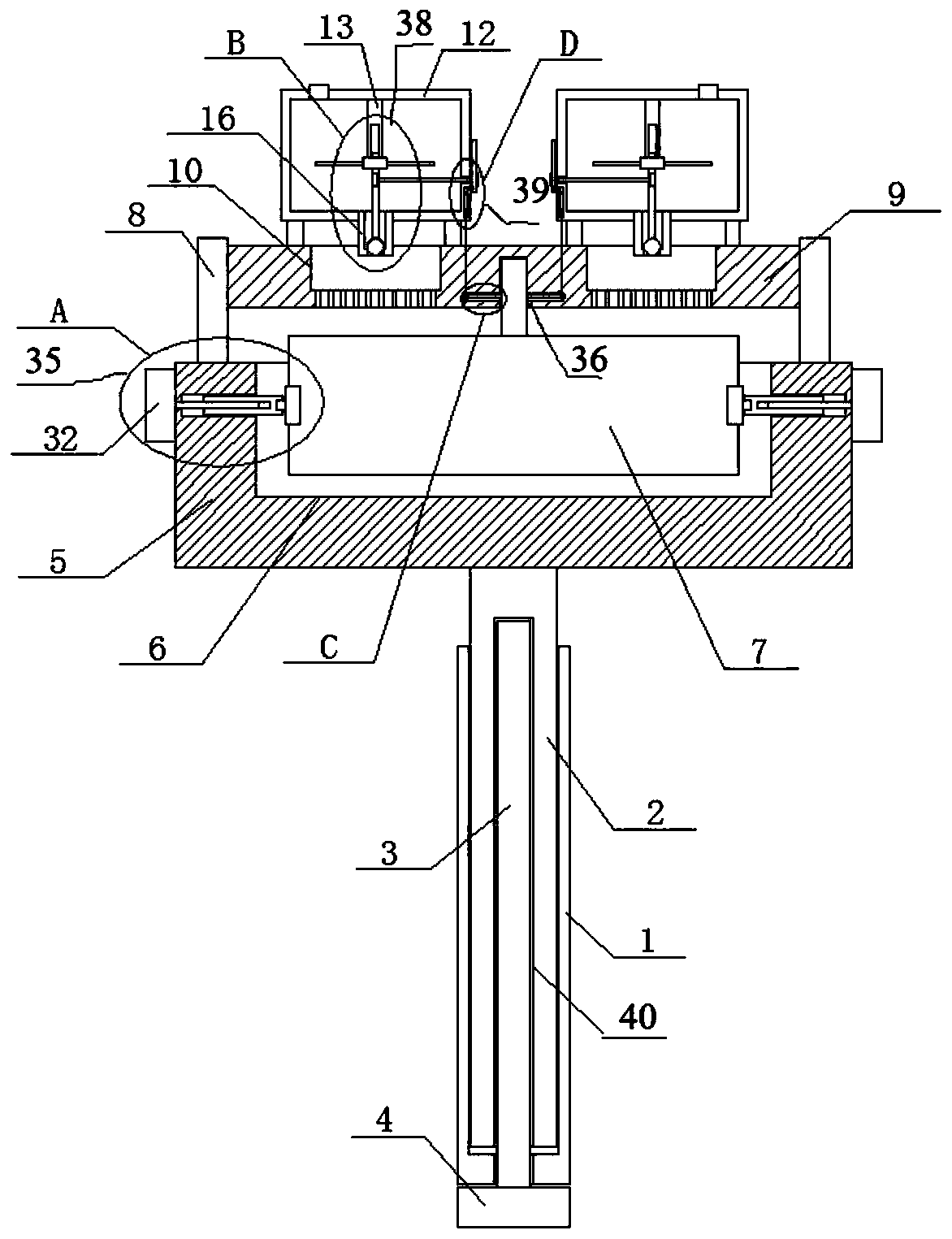

[0049] Such as Figure 1 to Figure 5 Shown, the present invention provides a kind of wall surface roller brush type paint device, and this device comprises:

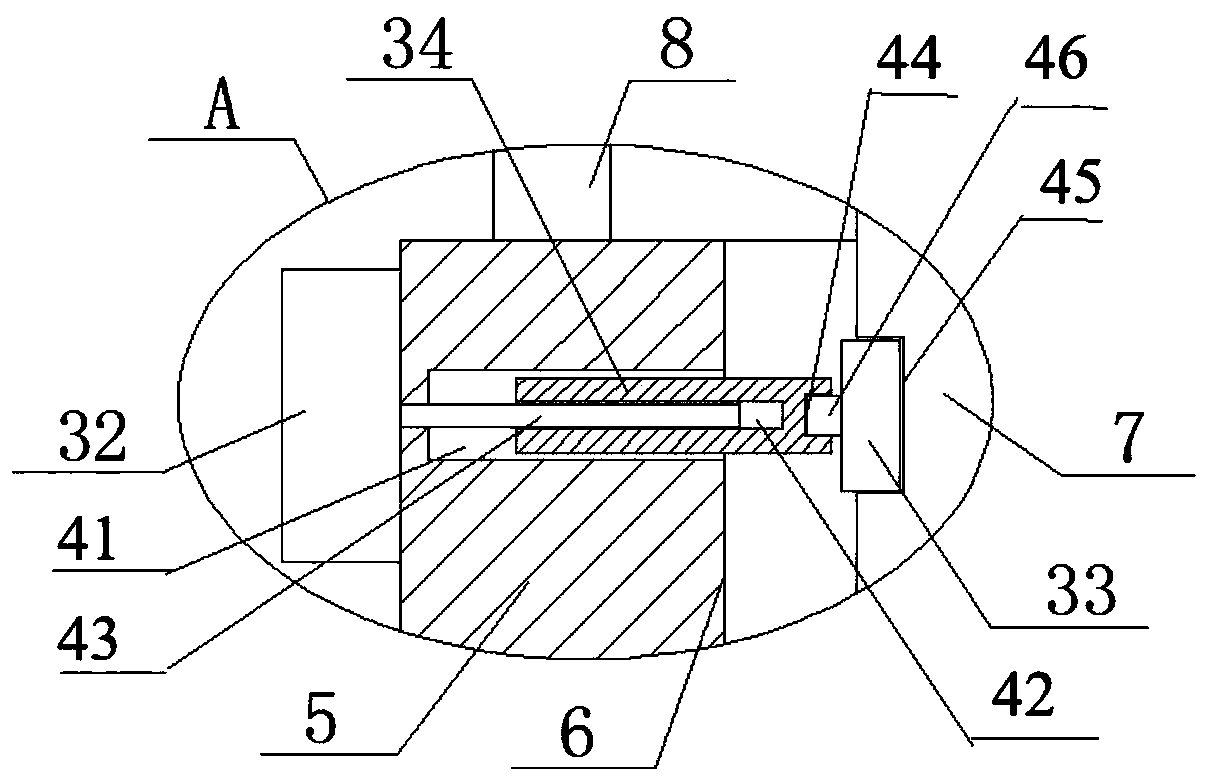

[0050] Rolling brush mechanism, the bottom of the rolling brush mechanism is provided with a fixed seat 5, the top of the fixed seat 5 is provided with a groove 6, the inside of the groove 6 is provided with a brush roller 7, and the two ends of the brush roller 7 are connected to the fixed seat 5 The connection is provided with a disassembly mechanism 35;

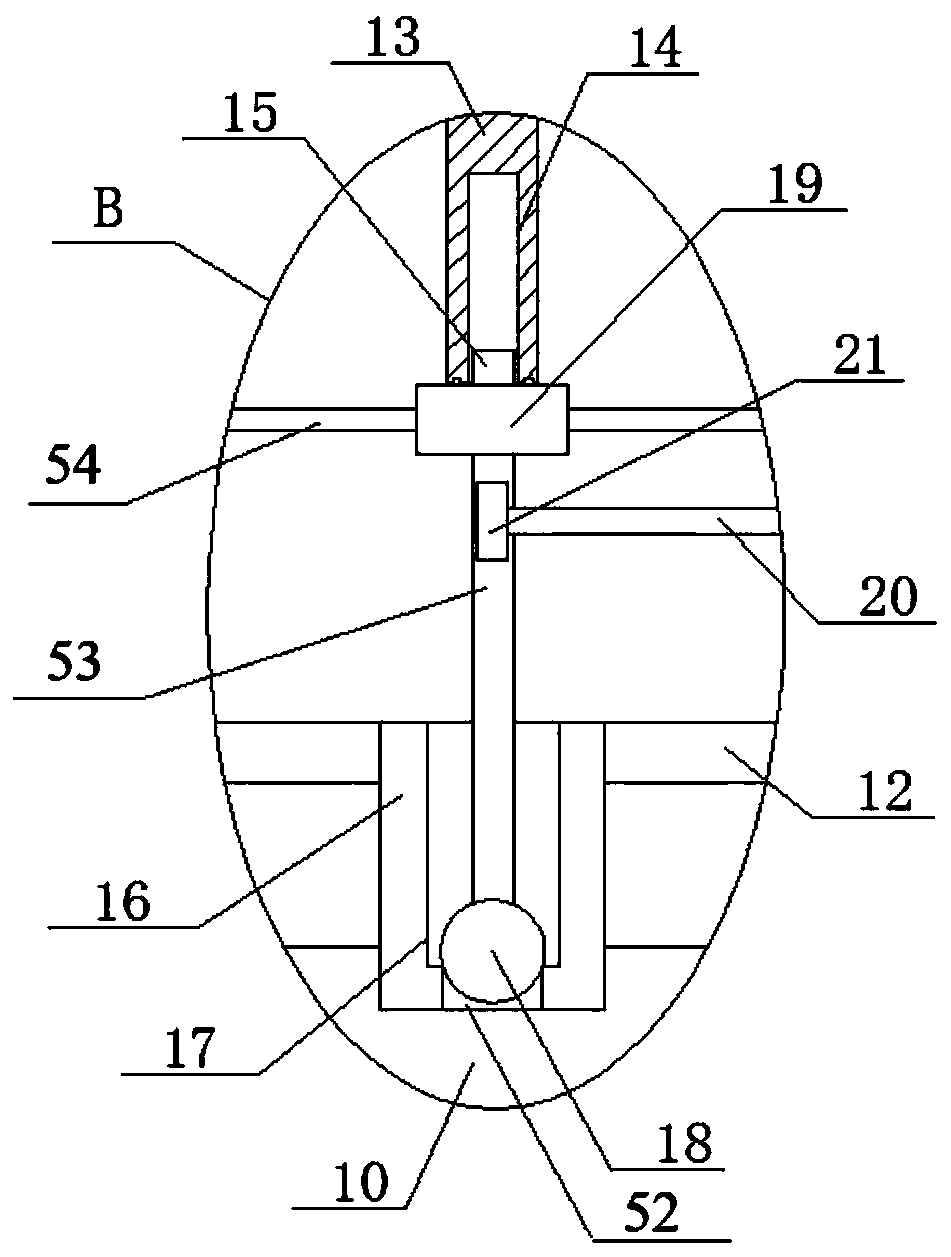

[0051] A discharge mechanism, the discharge mechanism is arranged above the roller brush mechanism, side plates 8 are arranged on both sides of the discharge mechanism, a connecting seat 9 is arranged between the two side plates 8, and the middle part of the connecting seat 9 is provided with A linkage mechanism 36, the upper side of the connecting seat 9 is provided with a collecting tank 10, the bottom of the collecting tank 10 is provided with a plurality of thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com