Aluminum alloy section paint spraying device

A technology of aluminum alloy profiles and paint spraying tubes, which is applied in spraying devices, spray booths, etc., can solve the problems of uneven and fine paint, and achieve the effects of improving the uniformity and refinement, ensuring the quality of painting, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

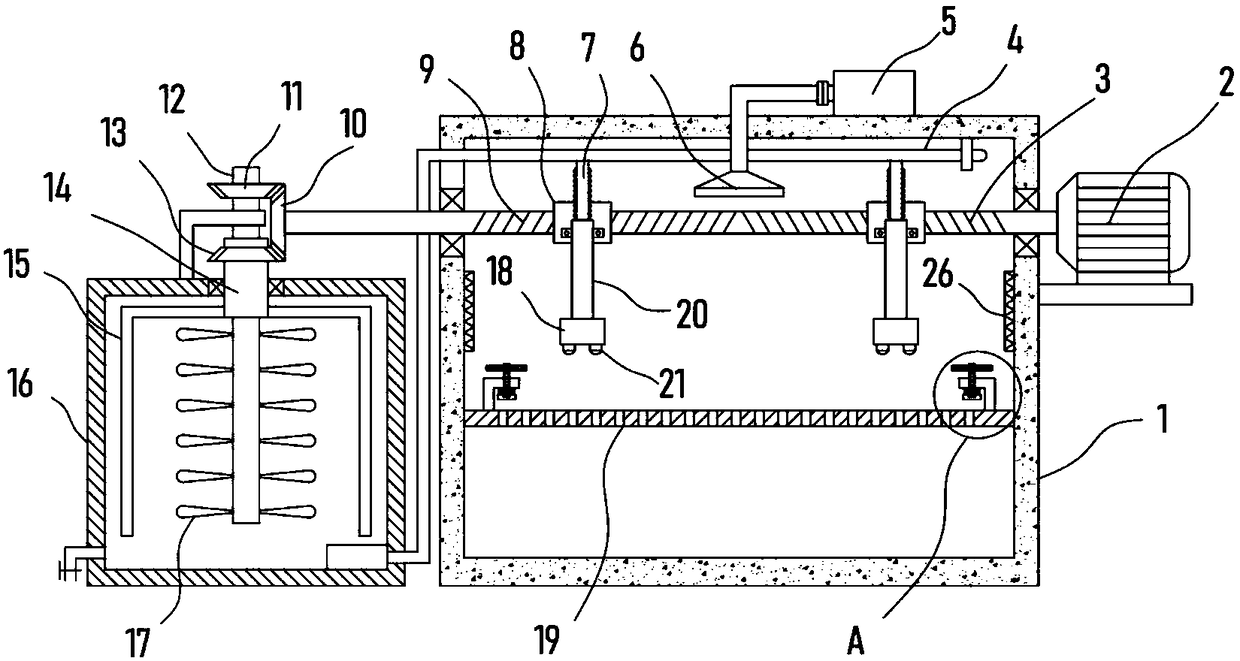

[0021] see Figure 1-3 , a paint spraying device for aluminum alloy profiles, including an operation frame 1, an operation frame 1 and a paint box 16, a support screen 19 is fixed horizontally on the operation frame 1, and a clamp for clamping an aluminum alloy profile is installed on the support screen 19 The holding device, the operating frame 1 is horizontally provided with a rotating shaft driven by the servo motor 2, and the rotating shaft is symmetrically tapped with external threads I3 and external threads II9 in opposite directions, and both external threads I3 and external threads II9 are sleeved A threaded sleeve block 8 is fixed.

[0022] The rotation shaft can be driven by the servo motor 2. The rotation shaft can realize the lateral movement of the threaded block 8 through the external thread I3 and the external thread II9. back exercise.

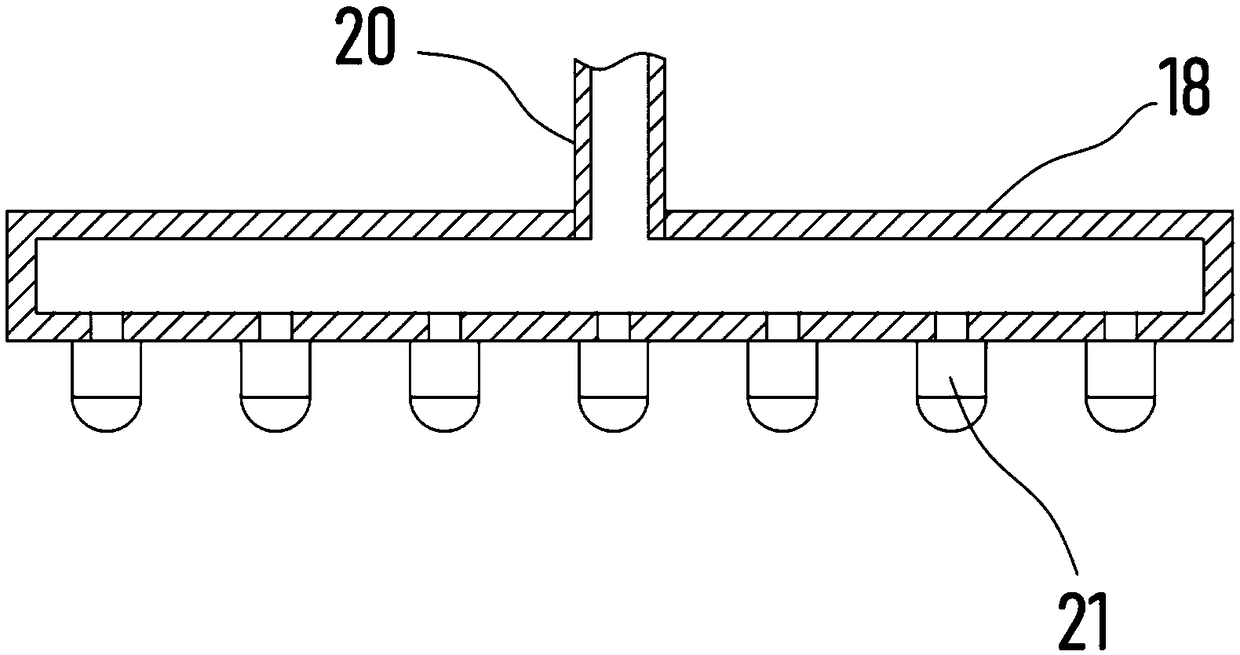

[0023] The threaded sleeve block 8 is vertically fixed with a paint spraying pipe 20, the lower end of the paint spraying p...

Embodiment 2

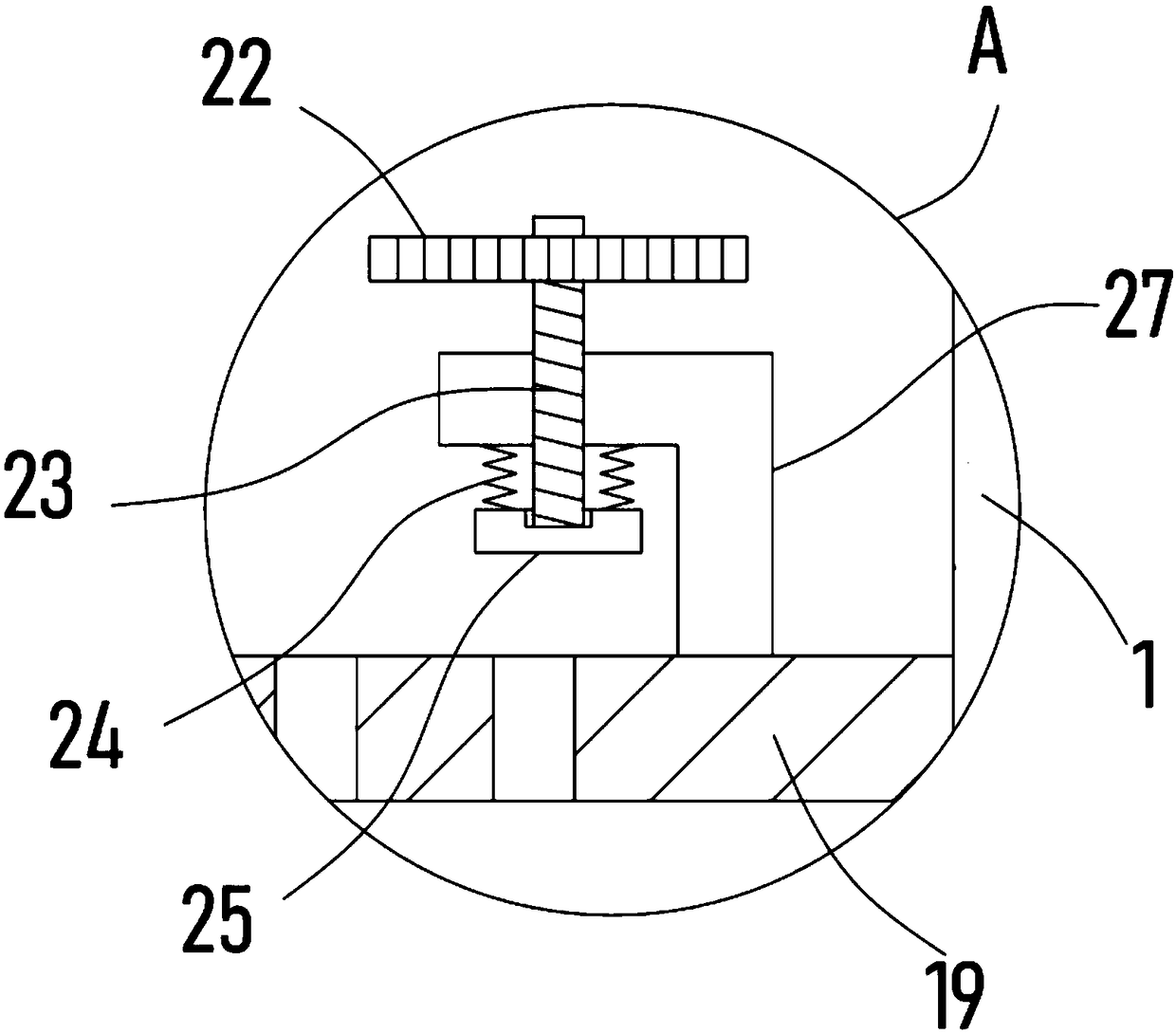

[0029] On the basis of Embodiment 1, in addition, the clamping device includes a support plate 27 fixed on the support net plate 19, a threaded rod 23 is threaded on the support plate 27, and a hand wheel 22 is sleeved and fixed on the upper end of the threaded rod 23. , the lower end of the threaded rod 23 abuts against a pressing plate 25 made of rubber, and a return spring 24 is vertically fixed between the pressing plate 25 and the support plate 27 .

[0030] The aluminum alloy profile is placed on the supporting net plate 19, and the rotating hand wheel 22 drives the threaded rod 23 to screw down. At this time, the pressing plate 25 is pressed by the threaded rod 23 and moves downward under the elastic force of the return spring 24 and The aluminum alloy profile is compressed and fixed, and the pressing plate 25 is made of rubber to protect the clamping process of the aluminum alloy profile and avoid damage to the surface of the aluminum alloy profile.

[0031] Further, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com