Energy-saving and environmental-protecting painting-drying-purification combination machine

An energy-saving and environment-friendly combined machine technology, which is applied in spray booths, spray devices, chemical instruments and methods, etc., can solve problems such as lack of systematic isolation measures, work environment pollution, paint mist diffusion, etc., achieve remarkable technical effects and ensure spray paint quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

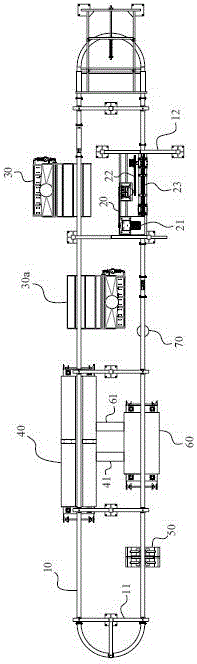

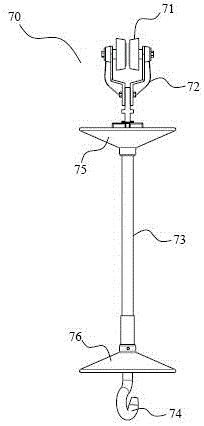

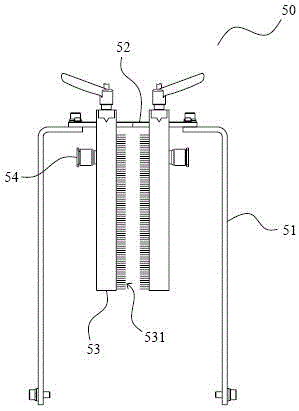

[0020] Such as figure 1 As shown, the present invention provides an energy-saving and environment-friendly spray painting-drying-purification combination machine, comprising a catenary system, a hoisting mechanism 70 is suspended below the catenary system, and the hoisting mechanism 70 circulates along the catenary system, And pass through the paint spray booth 30, the paint film drying device 40, the catenary cleaning device 50 and the catenary drying device 60 in sequence. In this scheme, the catenary system can be in the shape of circular track or S-shaped and other shapes. What this scheme adopts is circular circular track; It is to provide an independent and relatively sealed painting environment for the workpiece, and the automatic or manual painting operation can be carried out through the paint spraying room 30; the paint film drying device 40 is mainly used for the rapid drying of the workpiece after painting, and the interior can adopt the existing technology. The h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com