Integrated renewable energy system

a renewable energy system and compression ignition technology, applied in the direction of dynamo-electric machines, electrogenerative processes, non-fuel substance addition to fuel, etc., can solve the problem that the carbon dioxide produced by the combustion process would not directly contribute to global warming, and achieve the effect of fuel efficiency and reducing environmental pollution of the engin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

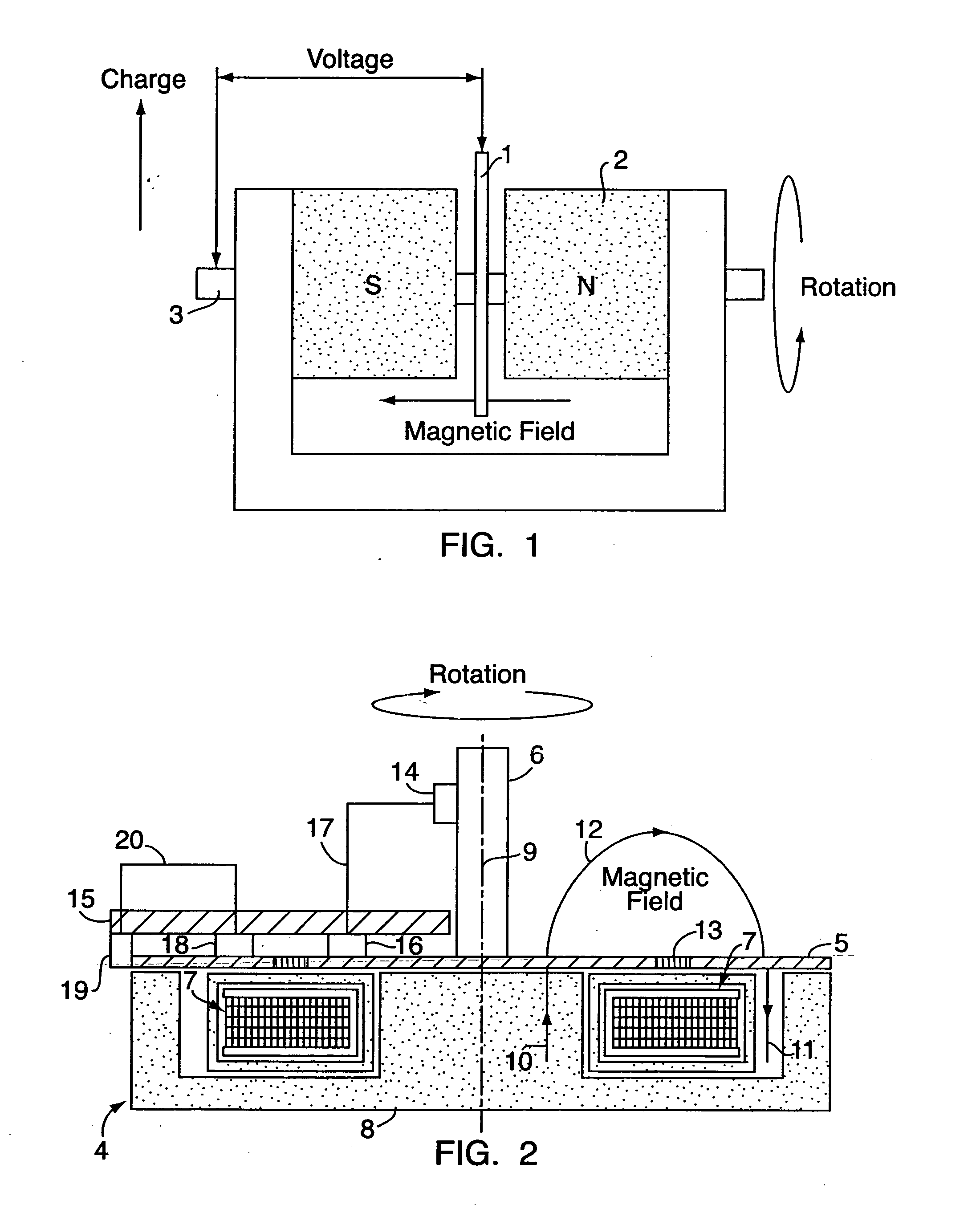

[0053] In FIG. 1, a shaft 3 runs through the center of both poles of a magnet 2, and in a manner whereby shaft 3 can freely rotate within the magnet 2. A metal disc 1 is fixed to shaft 3 and is spatially arranged so that the metal disc 1 is centrally located between the north and south poles of the magnet 2.

[0054] Rotation of shaft 3, by the application of an external rotating force, correspondingly rotates the metal disc 1 between the poles of the magnet 2, so that the disc intersects the magnetic field produced by the magnet.

[0055] Rotation of disc 1 in the magnetic field generates a voltage between the center of the disc and the rim of the disc. An electric charge, which can be collected by electrical contact brushes placed at the rim and at the center of the disc, is produced in disc 1.

[0056] The efficiency of a homopolar generator is greatly improved if an annular magnetic field, whose axis passes through the center of the drive shaft, is used in the system. When an annular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com