Automatic powder filling and packaging device and method

An automatic filling and filling device technology, which is applied in packaging, packaging machines, transportation and packaging, etc., can solve the problems of environmental pollution and health hazards, and achieve the effects of reducing environmental pollution, reducing intermediate links, and avoiding human injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

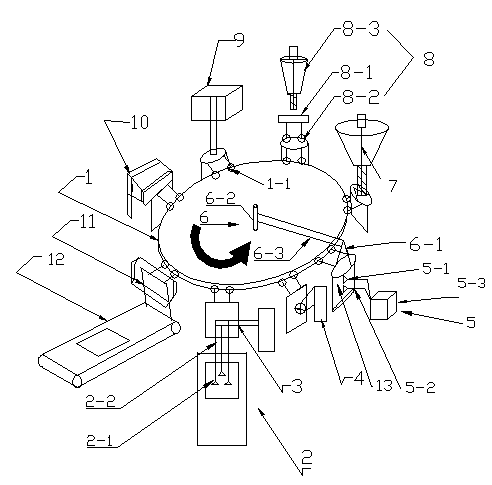

[0017] refer to figure 1 , a device for automatic filling and packaging of powder, comprising a packaging bag pre-processing mechanism 2 with a compression pulley 2-1 and a conveyor belt 2-2, a bag taking manipulator 3, an automatic inkjet printer 4, and a bag opening Device 5, bag supporting device 6, volume filling device 7, weighing and filling device 8, vacuum cleaner 9, heat sealing machine 10, embossing and shaping device 11, finished product conveyor belt 12, and a mechanical clamp with eight sets of turntables 1- 1 circular turntable 1, circular turntable 1, packaging bag pre-processing mechanism 2, bag taking robot 3, automatic inkjet printer 4, bag opening device 5, bag supporting device 6, volume filling device 7, weighing filling device 8 , vacuum cleaner 9, heat sealing machine 10, embossing and shaping device 11, and finished product conveyor belt 12 are all connected to the PCL controller, the circular turntable 1 is driven by gears, and eight sets of turntable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com