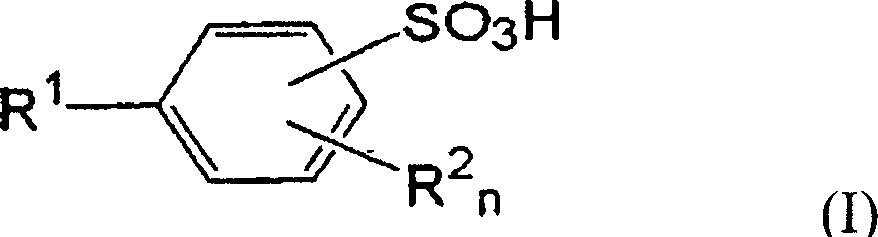

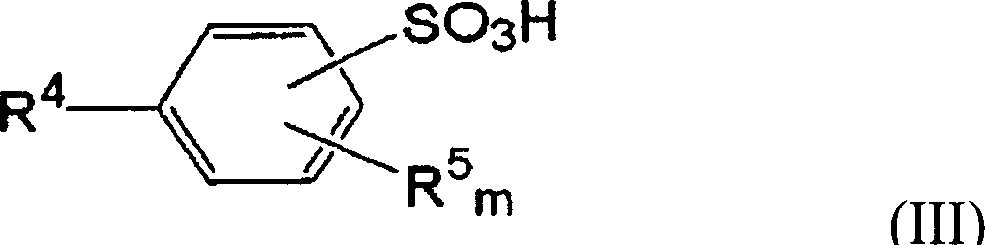

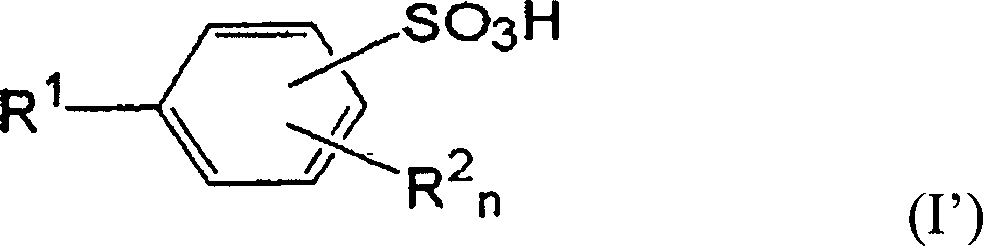

Method for producing binder resin, particulate resin dispersion, electrostatic image development toner, electrostatic image developer, and image forming method

A technology of electrostatic image development and binder resin, which is applied in the direction of developer, electric recording process applying charge pattern, electric recording process applying electric charge pattern, etc. High fluidity, contamination suppression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0344] The present invention will be further described in the following examples, but the present invention is not limited thereto.

[0345] 1) Examples of bulk polymerization

Embodiment A-1-1

[0347] 1,4-Cyclohexanedicarboxylic acid: 17.5 parts by weight

[0348] Bisphenol A-ethylene oxide 2 mol adduct: 31.0 parts by weight

[0349] N-dodecylbenzene sulfonic acid: 0.6 parts by weight (1 mol% relative to the total monomer)

[0350] Branched dodecyl benzene sulfonic acid (Tayca Power B120, manufactured by Tayca): 0.6 parts by weight (1 mol% relative to the total amount of monomers)

[0351] The above-mentioned materials are mixed, and then put into a 200-ml reactor equipped with a stirrer, and then the monomer is subjected to polycondensation reaction therein to obtain a uniform and transparent non-crystalline polyester resin.

[0352] Weight average molecular weight measured by GPC: 12,000

[0353] Glass transition temperature (start): 55℃

[0354]Put the obtained resin into a three-necked flask equipped with a stirrer and a cooling tube, and then gradually add 1N NaOH aqueous solution with stirring while maintaining 95°C. When the total amount of the NaOH aqueous soluti...

Embodiment A-1-2

[0356] 1,4-Cyclohexanedicarboxylic acid: 17.5 parts by weight

[0357] Bisphenol A-ethylene oxide 2 mol adduct: 31.0 parts by weight

[0358] N-dodecylbenzene sulfonic acid: 0.06 parts by weight (relative to the total amount of monomers is 0.1 mol%)

[0359] Branched dodecylbenzene sulfonic acid (Tayca Power B120, manufactured by Tayca): 0.06 parts by weight (relative to the total amount of monomers, 0.1 mol%)

[0360] The above materials were mixed, and then put into a 200 ml reactor equipped with a stirrer, and then subjected to a polycondensation reaction at 120°C for 24 hours to obtain a uniform and transparent amorphous polyester resin.

[0361] Weight average molecular weight measured by GPC: 14,500

[0362] Glass transition temperature (start): 55.5℃

[0363] Then, a resin particle dispersion with a median diameter of 420 nm was prepared in the same manner as in Example A-1-1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com