Method for preparing high-strength high-modulus organosilicone modified PI/SiO2 hybridization film

A high-strength, high-modulus, organosilicon technology, which is applied in the field of preparation of high-strength and high-modulus organosilicon modified PI/SiO2 hybrid films, can solve the problems of polyimide material voids, difficulty in meeting high-strength and high-modulus, affecting mechanical properties, etc. , to achieve the effect of good uniformity and accuracy, excellent comprehensive performance, and large molecular weight of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

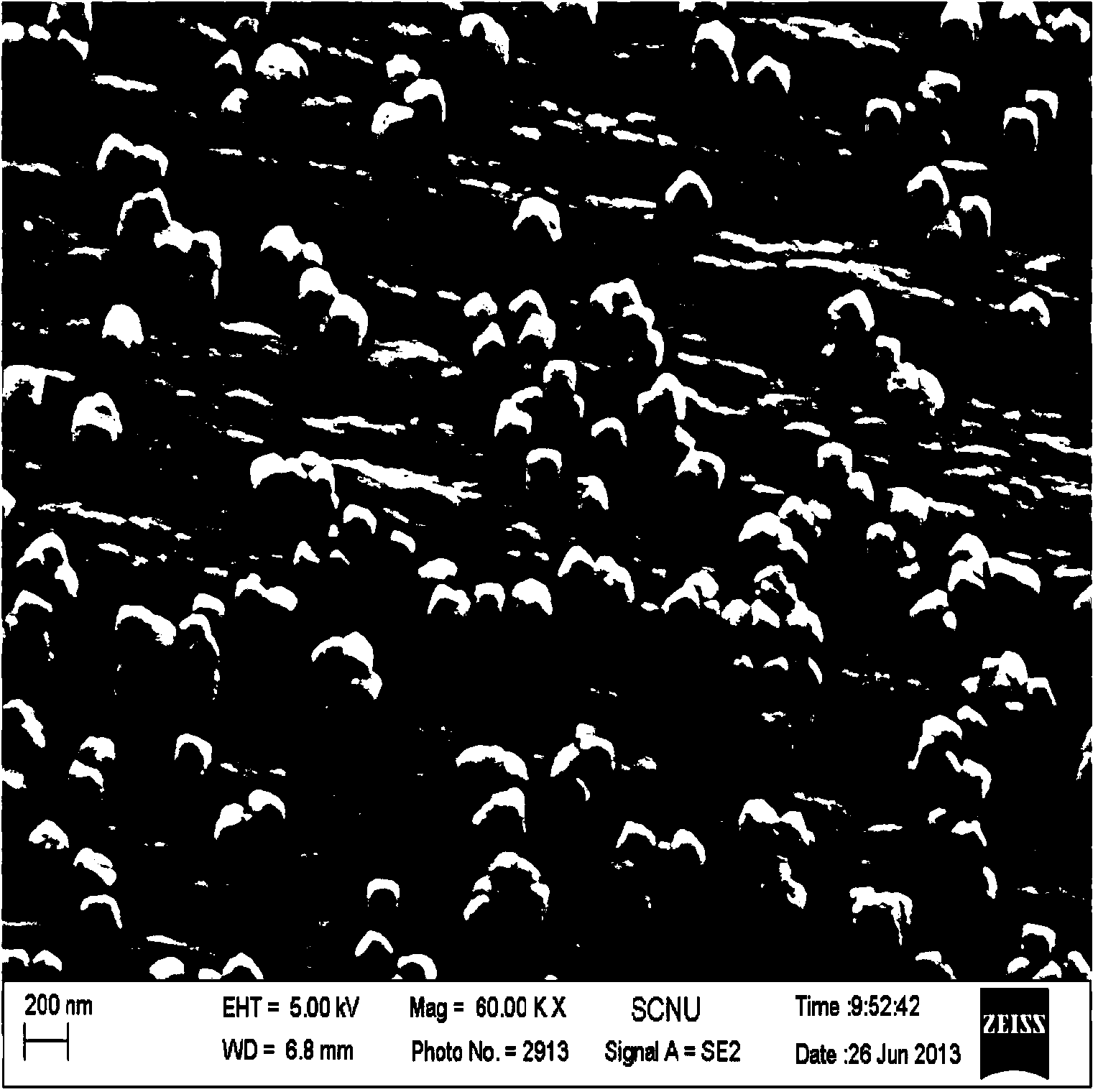

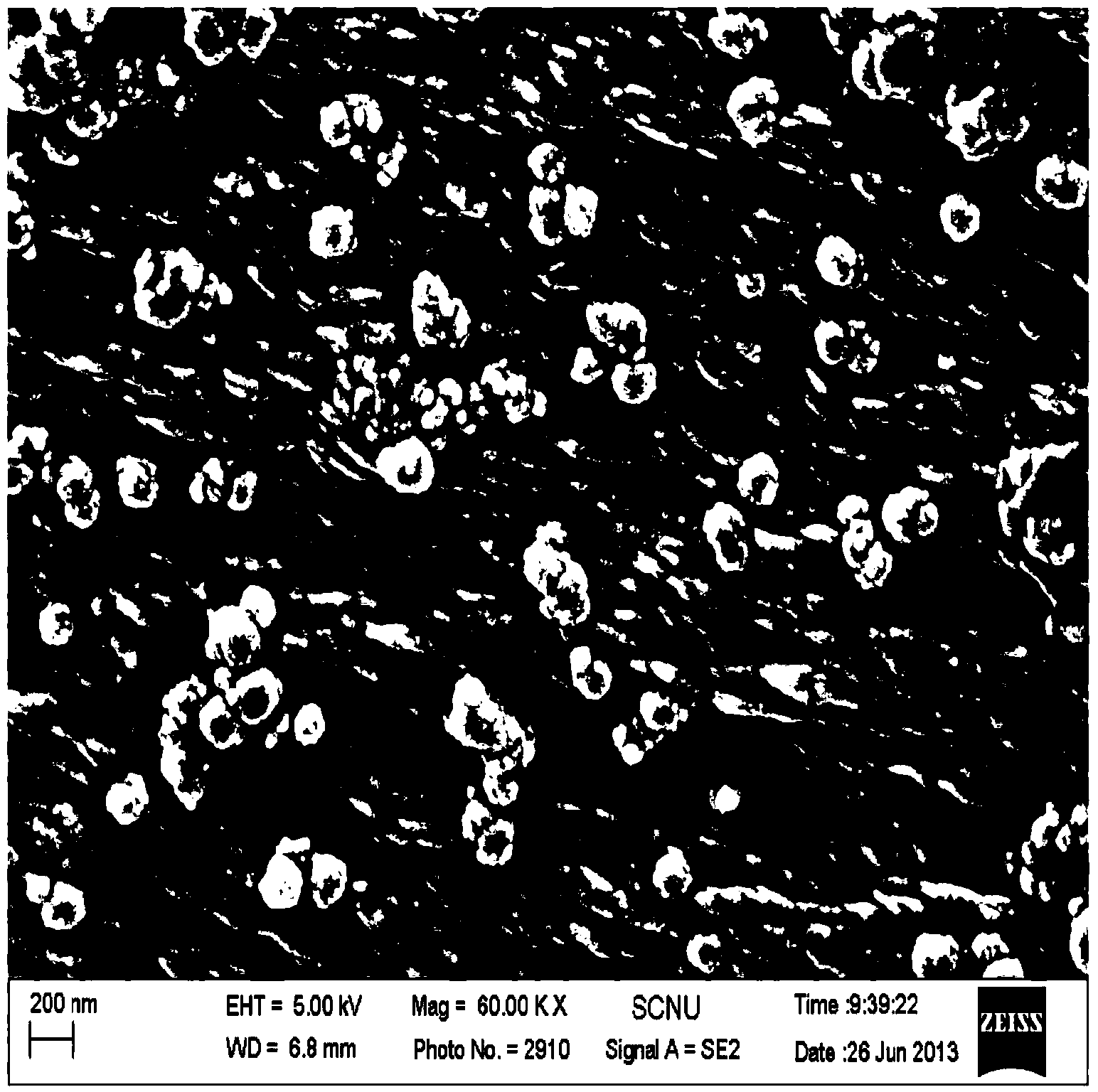

Image

Examples

preparation example Construction

[0031] High-strength and high-modulus organosilicon modified PI / SiO 2 The preparation method of the hybrid thin film is characterized in that the specific preparation steps are as follows:

[0032] (1) Add the aromatic dianhydride into the organic solvent, control the temperature at 20-30°C, dissolve under stirring, add the aminosilane coupling agent, keep the temperature and stir, and react for 3-8 hours;

[0033] (2) Add the aromatic diamine into the organic solvent, control the temperature at 20-30°C, dissolve under stirring, add the aromatic dianhydride and the system of step (1), then add ethyl orthosilicate, control the temperature Keep stirring at 30-40°C, and react for 4-6 hours to obtain a silicone-modified polyamic acid resin solution;

[0034] (3) Dilute the silicone-modified polyamic acid resin solution in the above step (2) with an organic solvent to a suitable coating viscosity, spread the film on a clean support after defoaming, and control the film thickness t...

Embodiment 1

[0047] Under the protection of a nitrogen atmosphere, add 0.004mol of pyromellitic dianhydride to 10ml of N,N-dimethylacetamide, control the temperature at 20°C, stir and dissolve, then add an equimolar amount of γ-aminopropyltriethoxy base silane, stirred at constant temperature, and reacted for 3 hours to obtain N, N-dimethylacetamide solution of organosilicon-modified aromatic dianhydride monomer;

[0048] Under the protection of nitrogen atmosphere, add 0.104mol 4,4-diaminodiphenyl ether into 250ml N,N-dimethylacetamide, control the temperature at 20°C, stir and dissolve, then add the above silicone modified aromatic dianhydride Monomer N,N-dimethylacetamide solution and 0.1mol pyromellitic dianhydride, then add 0.00312mol ethyl orthosilicate, control the temperature at 30°C, stir and react for 4 hours to obtain a viscosity of 3050Pa. The organosilicon-modified polyamic acid resin solution of s;

[0049] Dilute the silicone-modified polyamic acid resin solution with N,N-d...

Embodiment 2

[0053] Under the protection of a helium atmosphere, add 0.01mol of biphenyltetracarboxylic dianhydride to 10ml of N,N-dimethylformamide, control the temperature at 30°C, stir and dissolve, then add an equimolar amount of γ-aminopropyltrimethoxy base silane, stirred at constant temperature, and obtained the N,N-dimethylformamide solution of organosilicon-modified aromatic dianhydride monomer after reacting for 8 hours;

[0054] Under the protection of a helium atmosphere, add 0.11mol of p-phenylenediamine to 250ml of N,N-dimethylformamide, control the temperature at 30°C, stir and dissolve, then add the N of the above silicone-modified aromatic dianhydride monomer , N-dimethylformamide solution and 0.1mol biphenyltetracarboxylic dianhydride, then add 0.0088mol ethyl orthosilicate, control the temperature at 40°C, stir and react for 6 hours to obtain a viscosity of 2950Pa. The organosilicon-modified polyamic acid resin solution of s;

[0055] Dilute the silicone-modified polyam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com