Catalyst composite and method for preparing polycarbonate

A technology of polycarbonate and composition, which is applied in the field of preparation of catalyst composition and polycarbonate, and can solve the problems of low catalytic activity and catalytic efficiency, poor control of polymer molecular weight, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0061] The catalyst composition provided by the invention is applied to the preparation of polycarbonate, so that the molecular weight of the polycarbonate is well controllable, thereby improving the medical value of the polycarbonate. Therefore the invention provides a kind of preparation method of polycarbonate, comprising:

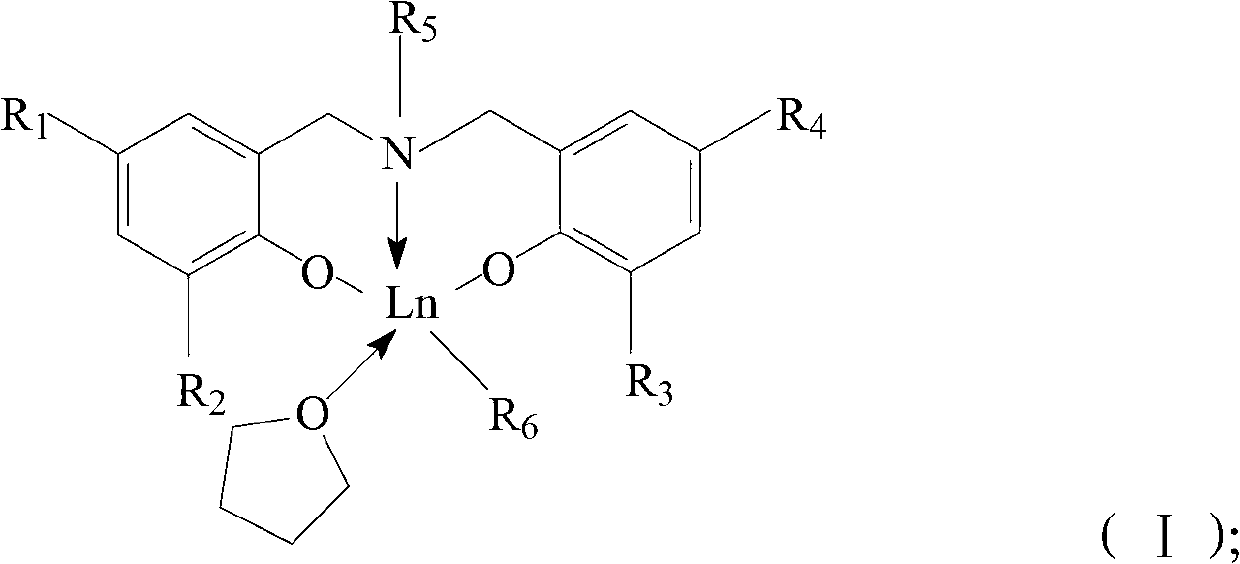

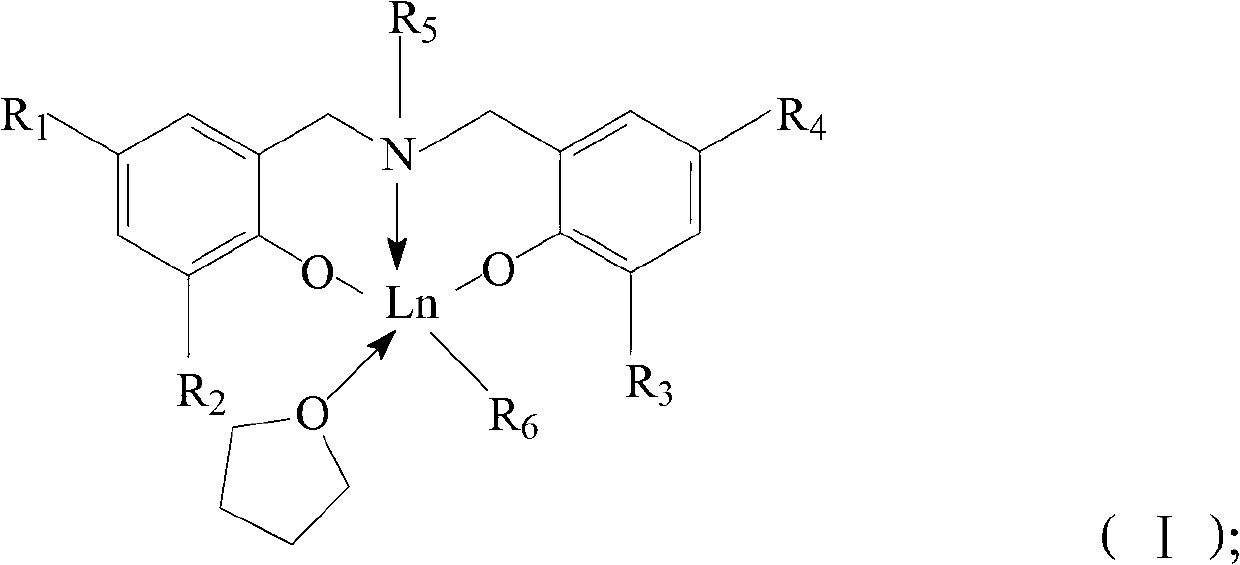

[0062] Under the action of the catalyst composition, the cyclocarbonate is polymerized in an organic solvent to obtain polycarbonate, the catalyst composition includes a rare earth metal complex and a hydroxyl compound having a structure of formula (I), and the rare earth metal The molar ratio of the complex to the hydroxyl compound is 1:1~500;

[0063]

[0064] Wherein, Ln is scandium, yttrium, lanthanum, cerium, praseodymium, neodymium, promethium, samarium, europium, gadolinium, terbium, dysprosium, holmium, erbium, thulium or ytterbium;

[0065] R 1 , R 2 , R 3 and R 4 each independently selected from hydrogen or C1~C10 alkyl;

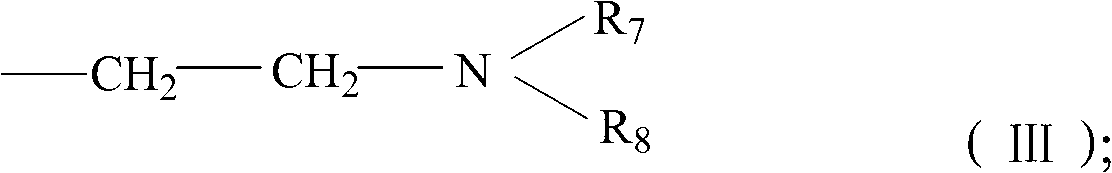

[0066] R 5...

Embodiment 1

[0082] In the reactor, add 3.0g (14.52mmol) of 2,4-di-tert-butylaniline, 0.81ml (7.38mmol) of dimethylethylenediamine, 1.51ml (20.16mmol) of 36% formaldehyde in water, and 10ml of methanol . 80 ° C reflux reaction for 24h. After the reaction mixed solution was cooled to room temperature, the supernatant liquid was poured out, and the oily substance in the lower layer was crushed in 9 ml of hot methanol solution to obtain 3.09 g of white powder, that is, the ligand with the structure of formula (IV). In the glove box, under the condition of -30°C, dissolve 0.019g of the ligand with the structure of formula (IV) in 10ml of n-hexane, and add it dropwise to 0.181g of Y (CH 2 Si(CH 3 ) 3 ) 3 (THF) 2 , In 5ml of n-ethane solution, keep the condition at -30°C for 12h. Wash the precipitate with n-hexane at -30°C to obtain a rare earth metal complex with the structure of formula (II), wherein, Ln is yttrium, R1 , R 2 , R 3 and R 4 is tert-butyl, R 7 and R 8 is methyl, R 6 F...

Embodiment 2

[0084] At room temperature, add 40 μmol of rare earth metal complexes, 40 μmol of benzyl alcohol, and 10 mL of tetrahydrofuran into a 25 mL polymerization bottle that has been treated with anhydrous and oxygen-free treatment, and react the polymerization bottle at 20 ° C for 5 minutes, then add 20 mmol of functionalized cyclocarbonate monomer, Then, after the polymerization reaction at 20°C for 0.5h, add an ethanol solution of hydrochloric acid with a volume fraction of 10% to the polymerization bottle to terminate the reaction, pour the reaction solution into ethanol to settle, filter to obtain a white solid, and place the solid in a vacuum After drying at 40° C. for 48 hours in a drying oven, a functionalized polycarbonate with a net weight of 2.31 g was obtained. Adopt nuclear magnetic test to detect the conversion rate of functionalized cyclocarbonate monomer, the result shows that monomer conversion rate is 98%; Adopt GPC analysis to obtain the molecular weight M of functi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com