Preparation and application of Al-SBA-15 mesoporous molecular sieve and fatty alcohol ethoxylation reaction method

A fatty alcohol ethoxy, mesoporous molecular sieve technology, applied in molecular sieve catalysts, chemical instruments and methods, ether preparation and other directions, can solve the problems of weak acidity, limited application scope, etc., achieve large specific surface area, good catalytic activity, product The effect of narrow molecular weight distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

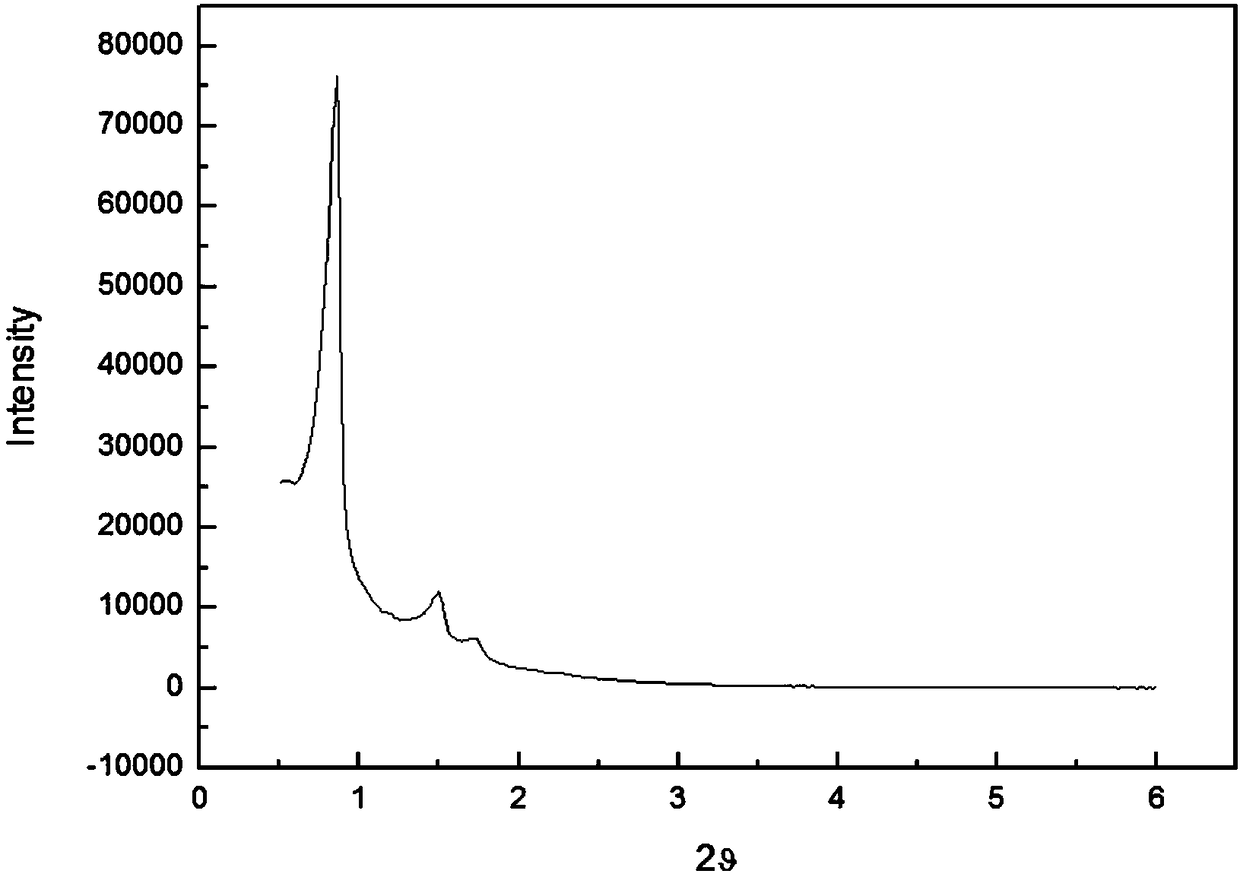

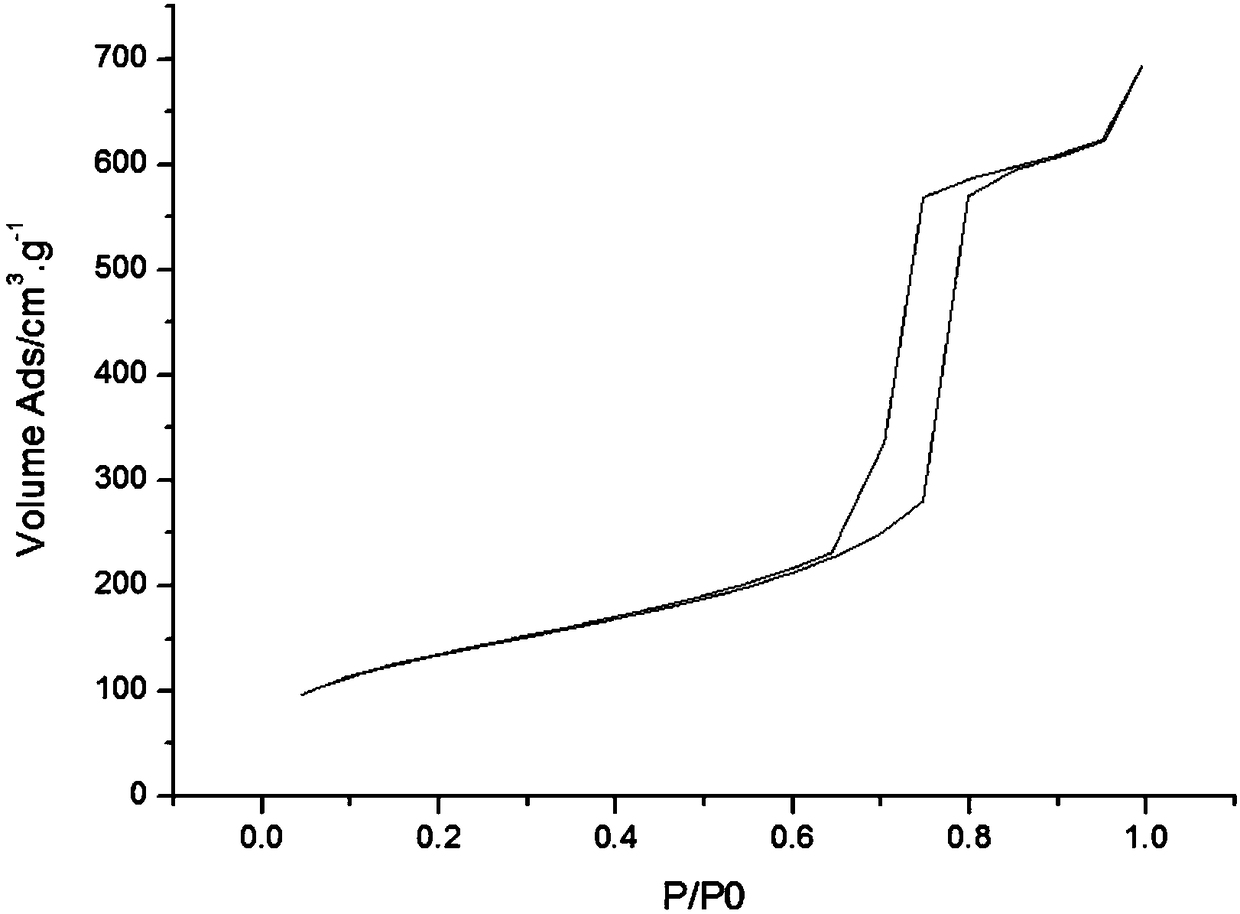

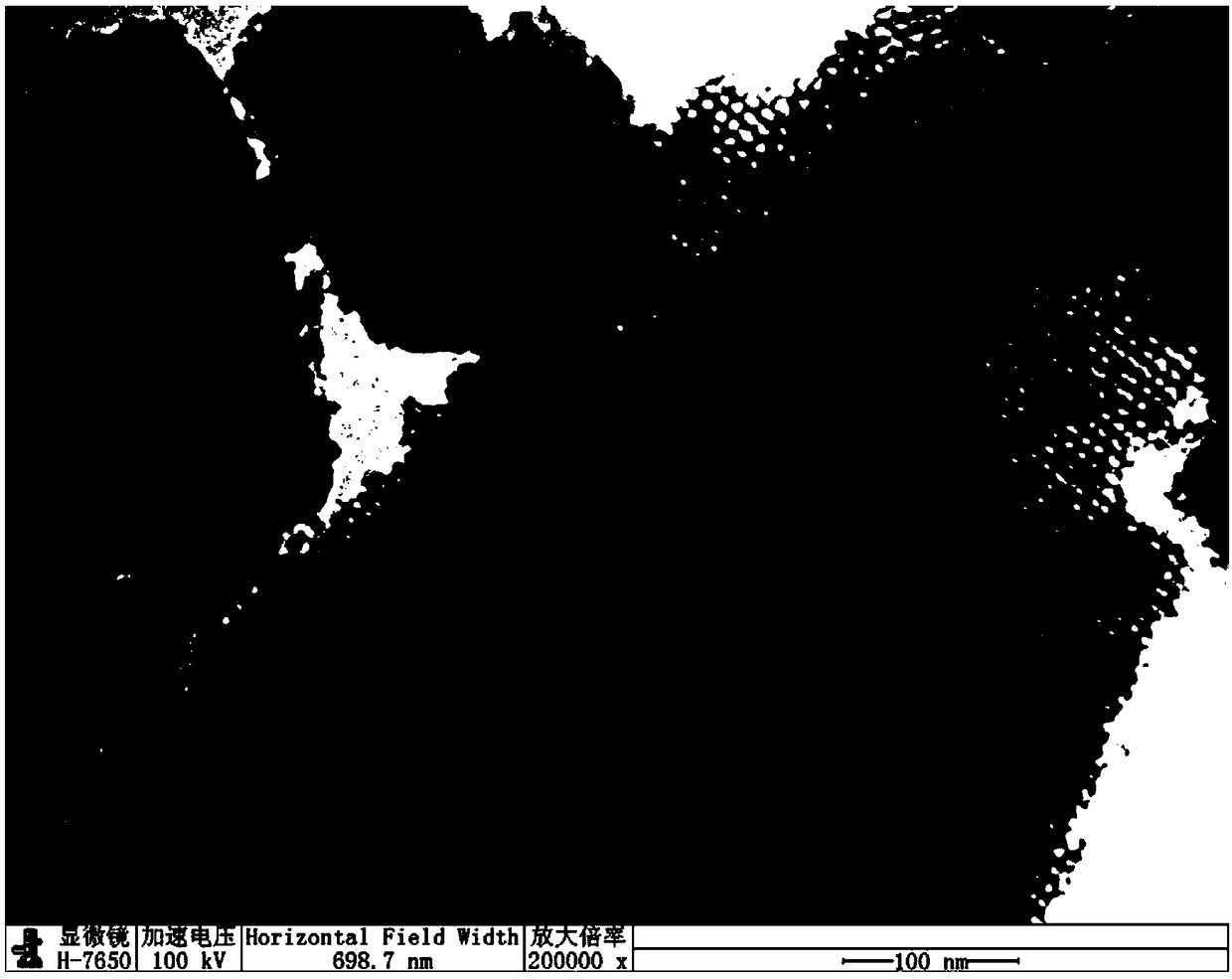

[0027] Embodiment 1: refer to figure 1 - image 3 , Al-SBA-15 mesoporous molecular sieve preparation method: Dissolve 4g P123 in 30g deionized water, add 120g 2mol•L-1HCl, stir at 38°C to obtain a transparent solution; then add 8.5g tetraethyl orthosilicate (TEOS) , according to n(Si):n(Al)= 30:1, add NaAlO 2 , stirred continuously at 38°C for 20 h; the mixed solution was transferred to a crystallization tank at 100°C for 2-3 days of crystallization, washed with deionized water, and dried in vacuum; -1 Rate-increased temperature calcination, stay at 540°C~560°C for 4h~6h; obtain Al-SBA-15 mesoporous molecular sieve.

Embodiment 2

[0028] Example 2: The reaction rate of Al-SBA-15 in the catalytic synthesis of n-octanol polyoxyethylene ether (determined by the reaction temperature).

[0029] Add 1mol (a certain amount) n-octanol, W (cat)%=7% (n-octanol) (the catalyst amount is 7% of n-octanol), when heated to 110°C, add 1mol ethylene oxide in batches, the initial pressure is 0.65 Mpa, at this time the ethylene oxide The alkanol reaction rate (moles of n-octanol reacted per mole of n-octanol per hour) is 3.2 mol.h -1 .

[0030] refer to Figure 4 ,from Figure 4 It can be seen that the temperature has a great influence on the reaction rate, and choosing an appropriate temperature is beneficial to the improvement of the product yield. At lower temperatures (below 100°C), the reaction between n-octanol and EO is very slow; the initial pressure is 0.65 MPa, and when the temperature is higher than 110°C, the reaction rate increases significantly with the increase of temperature, but As the temperature rises...

Embodiment 3

[0031] Example 3: The reaction rate of Al-SBA-15 in the catalytic synthesis of n-octanol polyoxyethylene ether (determined by the initial pressure).

[0032] Add 1mol n-octanol, W (cat)%=5~7% (n-octanol) (the catalyst amount is 5%~7% of n-octanol), the reaction temperature is 110°C~130°C, 1mol ethylene oxide is added in batches, and the initial pressure is 0.9 Mpa, the reaction rate of ethylene oxide is 4.2 mol.h -1 .

[0033] refer to Figure 5 ,from Figure 5 It can be seen that the initial pressure of the reaction system has a great influence on the reaction rate. As the system pressure increases, the reaction rate increases significantly. Because the reaction system pressure is too high, the reaction is too violent, and the reaction temperature rises too fast, which will lead to an increase in side reactions. . At the same time, the pressure of the reaction system is too high for the reactor. Therefore, the initial pressure of the reaction is selected to be 0.60-1.0 M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com