Impregnating phenolic resin and preparation method and application thereof

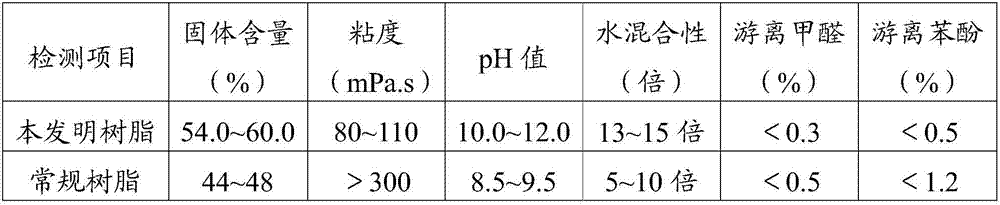

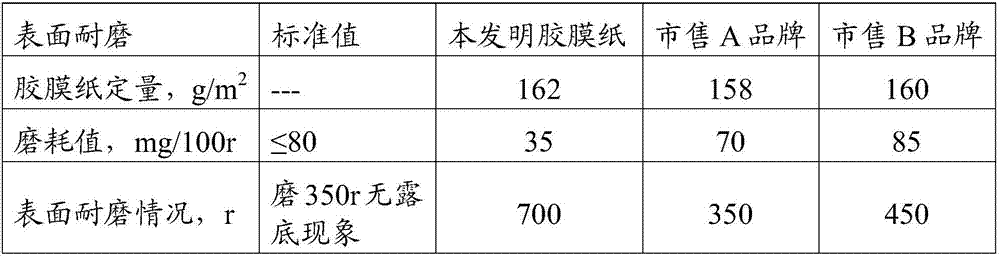

A technology of phenolic resin and impregnation solution, which is applied in the field of phenolic resin, can solve the problems of reduced quality of film paper, low solid content, uneven color, etc., and achieve the effect of ensuring resin performance, uniform and full color, and uniform molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] An embodiment of the impregnating phenolic resin described in the present invention. In the present embodiment, the synthetic method of described phenolic resin for impregnating comprises the following steps:

[0067] (1) After adding the first batch of formaldehyde and the first batch of liquid caustic soda, add water, add the first batch of urea after stirring for 5 minutes, and continue stirring;

[0068] (2) Add phenol, add the remaining liquid caustic soda, and control the temperature during the feeding process not to exceed 65°C;

[0069] (3) Slowly add the remaining formaldehyde after adding the liquid caustic soda, and control the temperature not to exceed 75°C during the feeding process;

[0070] (4) Allow the exothermic reaction to slowly heat up to 78°C, heat the reaction at 78°C until the viscosity reaches 20-24 seconds / 35°C B4, and immediately cool down;

[0071] (5) When the temperature is lowered to 70°C, add the remaining urea and cool to below 30°C; ...

Embodiment 2

[0076] An embodiment of the impregnating phenolic resin described in the present invention. In the present embodiment, the synthetic method of described phenolic resin for impregnating comprises the following steps:

[0077] (1) After adding the first batch of formaldehyde and the first batch of liquid caustic soda, add water, add the first batch of urea after stirring for 5 minutes, and continue stirring;

[0078] (2) Add phenol, add the remaining liquid caustic soda, and control the temperature during the feeding process not to exceed 65°C;

[0079] (3) Slowly add the remaining formaldehyde after adding the liquid caustic soda, and control the temperature not to exceed 75°C during the feeding process;

[0080] (4) Allow the exothermic reaction to slowly heat up to 85°C, heat the reaction at 82°C until the viscosity reaches 20-24 seconds / 35°C B4, and immediately cool down;

[0081] (5) When the temperature is lowered to 80°C, add the remaining urea and cool to below 30°C; ...

Embodiment 3

[0086] An embodiment of the impregnating phenolic resin described in the present invention. In the present embodiment, the synthetic method of described phenolic resin for impregnating comprises the following steps:

[0087] (1) After adding the first batch of formaldehyde and the first batch of liquid caustic soda, add water, add the first batch of urea after stirring for 5 minutes, and continue stirring;

[0088] (2) Add phenol, add the remaining liquid caustic soda, and control the temperature during the feeding process not to exceed 65°C;

[0089] (3) Slowly add the remaining formaldehyde after adding the liquid caustic soda, and control the temperature not to exceed 75°C during the feeding process;

[0090] (4) Allow the exothermic reaction to slowly heat up to 82°C, heat the reaction at 82°C until the viscosity reaches 20-24 seconds / 35°C B4, and immediately cool down;

[0091] (5) When the temperature is lowered to 75°C, add the remaining urea and cool to below 30°C; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com