Room temperature curing high-temperature-resistant high-tenacity epoxy adhesive and preparation method thereof

An epoxy adhesive, room temperature curing technology, used in adhesives, epoxy resin adhesives, polymer adhesive additives, etc., can solve the problem of poor toughening effect and heat resistance, and achieve excellent shear strength and excellent toughness. , cheap and easy to obtain effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

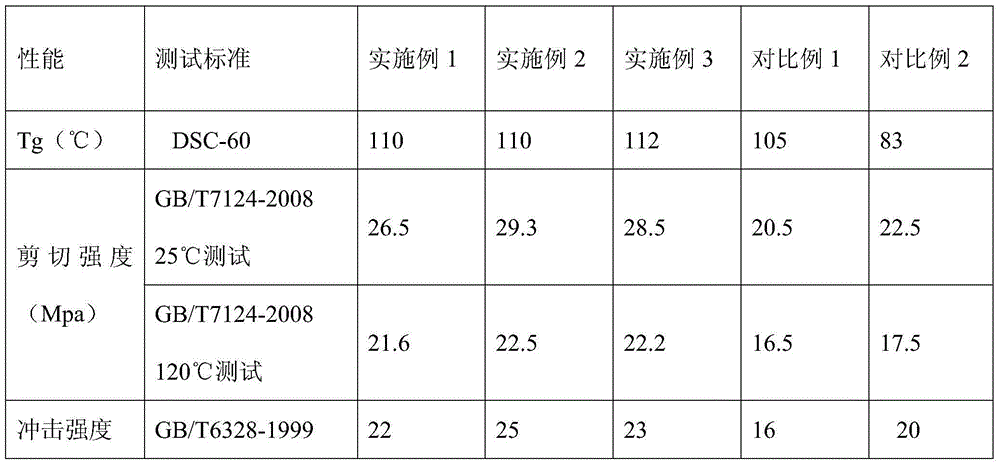

Examples

Embodiment 1

[0020] A room-temperature-curable, high-temperature-resistant, high-toughness epoxy adhesive. The raw materials in terms of weight percent include: 30% of component A and 70% of component B. The raw materials of component A in terms of weight percent include: 75% of E51 epoxy resin 10% epoxy resin toughening agent modified by nano core-shell particles, 2% dodecyl to tetradecyl glycidyl ether, 0.5% polysiloxane coupling agent, 0.5% hydrophobic fumed silica, talc Powder 11.9%, polydimethylsiloxane defoamer 0.1%, the raw materials of the B component according to weight percentage include: alicyclic amine 35%, polyamide 25%, modified fatty amine 15%, amino silicone Alkane coupling agent coupling agent 0.5%, hydrophobic fumed silica 0.5%, aluminum oxide 1%, polydimethylsiloxane defoamer 0.1%.

[0021] The preparation method of the room temperature curing epoxy adhesive with high temperature resistance and high toughness, the specific steps are as follows:

[0022] (1) Taking mater...

Embodiment 2

[0027] An epoxy adhesive cured at room temperature with high temperature resistance and high toughness, the raw materials according to weight percentage include: 32% of component A, 68% of component B, and the raw materials of component A according to weight percentage include: 70% of E51 epoxy resin 15% epoxy resin toughening agent modified by nano core-shell particles, 2% dodecyl to tetradecyl glycidyl ether, 0.5% modified polysiloxane coupling agent, 0.5% hydrophobic fumed silica , aluminum oxide 11.9%, tributyl phosphate defoamer 0.1%, the raw materials of the B component according to weight percentage include: alicyclic amine 30%, polyamide 25%, modified fatty amine 15%, mercaptosiloxane Coupling agent 0.5% coupling agent, 0.5% hydrophobic fumed silica, 28.9% calcium carbonate, 0.1% tributyl phosphate defoamer.

[0028] The preparation method of the room temperature curing epoxy adhesive with high temperature resistance and high toughness, the specific steps are as follow...

Embodiment 3

[0034] An epoxy adhesive cured at room temperature with high temperature resistance and high toughness, the raw materials according to weight percentage include: 35% of component A, 65% of component B, and the raw materials of component A according to weight percentage include: 72% of E51 epoxy resin 12.5% epoxy resin toughening agent modified by nano core-shell particles, 2% dodecyl to tetradecyl glycidyl ether, 0.5% polysiloxane coupling agent, 0.5% hydrophobic fumed silica, talc Powder 12.4%, polydimethylsiloxane defoamer 0.1%, the raw materials of the B component according to weight percentage include: alicyclic amine 40%, polyamide 20%, modified fatty amine 15%, amino silicone 0.5% alkane coupling agent, 0.5% hydrophobic fumed silica, 23.9% talcum powder, and 0.1% polydimethylsiloxane defoamer.

[0035] The preparation method of the room temperature curing epoxy adhesive with high temperature resistance and high toughness, the specific steps are as follows:

[0036] (1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com