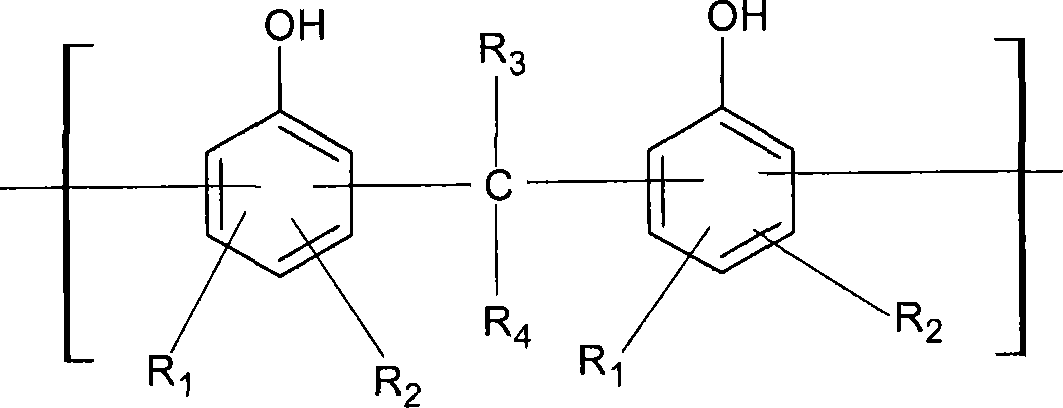

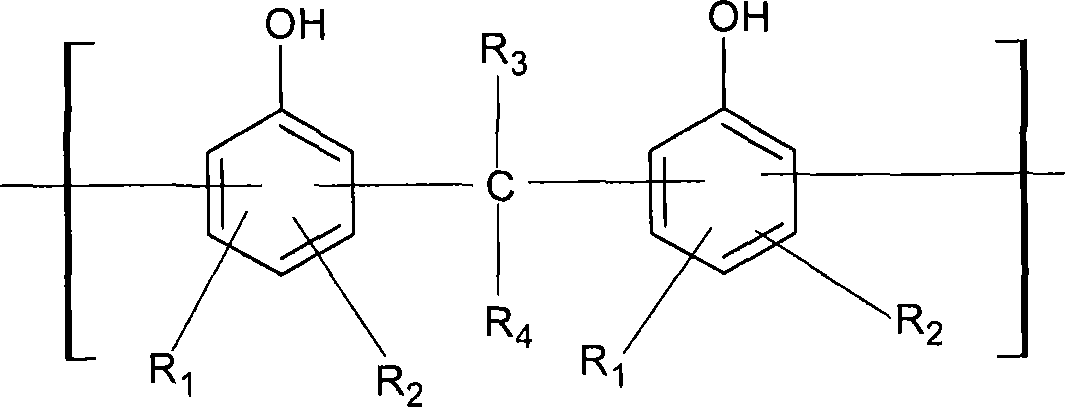

Resorcin phenolic resin modified rubber composition

A technology of resorcinol and composition is applied in the application field of rubber compound resin in the preparation of pneumatic tires, pressure pipes and belts, and can solve the problem of high content of free resorcinol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

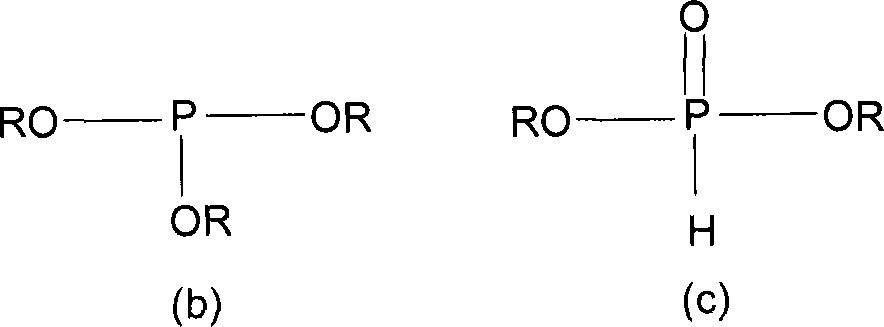

Method used

Image

Examples

Embodiment 1

[0040] In a 500ml round-bottomed reaction flask equipped with a stirrer, thermometer, reflux condenser and dropping funnel, add 165.1g (1.5 moles) of resorcinol and 10.71g of triphenyl phosphite catalyst (TPP), and heat Blend until melted. Then, 78.1 g (0.93 mol) of formaldehyde aqueous solution was slowly added dropwise to the molten resorcinol within about 90-120 minutes. After the dropwise addition of formaldehyde is completed, the reactant is dehydrated and evaporated to remove all volatiles in the flask until the temperature rises to about 150°C to 160°C. Then, 72.6 g (0.705 moles) of styrene was added to the molten resorcinol-formaldehyde reaction liquid under the condition of increasing temperature, and the dropping time was controlled for about 60 to 120 minutes. After the styrene addition was completed, 5.6 g of NaOH aqueous solution was added to neutralize the acid catalyst. Finally, vacuum dehydration was carried out to obtain a tan resin with a softening point of...

Embodiment 2

[0042] In a 500ml round-bottomed reaction flask equipped with a stirrer, thermometer, reflux condenser and dropping funnel, add 165.1g (1.5 moles) of resorcinol and 10.71g of triphenyl phosphite catalyst (TPP), and heat Blend until melted. Then, 71.25 g (0.675 mol) of styrene was added dropwise to the molten resorcinol, and the dropping time was controlled to be 120 minutes. Then slowly add 77.5 g (0.93 moles) of formaldehyde aqueous solution to the molten resorcinol-styrene reaction solution within about 90-120 minutes. After the dropwise addition of formaldehyde is completed, the reactant is dehydrated and evaporated to remove all volatiles in the flask until the temperature rises to about 150°C to 160°C. Then, add 16.5 g (1.15 moles) of styrene to the resorcinol-styrene-formaldehyde reaction liquid in about 60 to 120 minutes under the condition of gradually increasing the temperature. After the dropwise addition, 5.5 g of NaOH aqueous solution was added to neutralize the ...

Embodiment 3

[0044] In a 500ml round bottom reaction flask equipped with stirrer, thermometer, reflux condenser and dropping funnel, add 165.1g (1.5mol) resorcinol and 10.71g triphenylphosphite catalyst (TPP), and heat Blend until melted. Then, 109.41 g (1.05 mol) of styrene was added dropwise to the molten resorcinol, and the dropping time was controlled to be 120 minutes. Then slowly add 78.75 g (0.945 moles) of formaldehyde solution to the molten resorcinol-styrene reaction liquid within about 90-120 minutes. After all the formaldehyde addition was complete, 5.5 g of aqueous NaOH was added to neutralize the acid catalyst. Finally, vacuum dehydration to obtain a red resin with a softening point of 105°C. HPLC analysis showed that the content of free resorcinol in the resin was 0.96%.

[0045] The resulting resin contained less than 1% free resorcinol and is considered to be a very low volatility resorcinol resin useful in many applications.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com