Electric heating rotary kiln

A rotary kiln and electric heating technology, applied in the field of rotary kiln, can solve the problems of low thermal efficiency and complex structure, and achieve the effects of high thermal efficiency, uniform heating and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

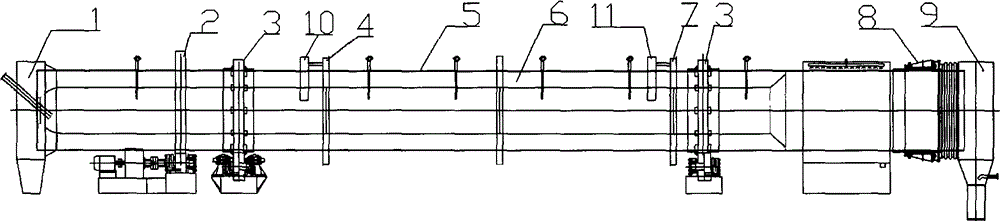

[0031] figure 1It is the schematic diagram of Embodiment 1, an electric heating rotary kiln device, which is used to dry or heat materials, including a rotary tube 5, a rotary tube thermal insulation part 6, a pulley 2, a load-bearing wheel 3, a heating system, and a kiln head inlet. For components such as material 1 and kiln tail discharge material 9, the part of the inner layer of the thermal insulation part that contacts the material is an insulating material. The electrodes are composed of a positive pole 10 and a negative pole 11, both of which pass through the rotary tube and the thermal insulation part 6, and are in contact with the materials in the chamber of the rotary kiln during work. Conductive rings 4 and 7 are fixed on the circumference of the outer wall of the revolving tube and electrically connected to the electrodes 10 and 11 respectively, and the power supply is connected to the conductive rings 4 and 7 through brushes. When working, the power supply curren...

Embodiment 2

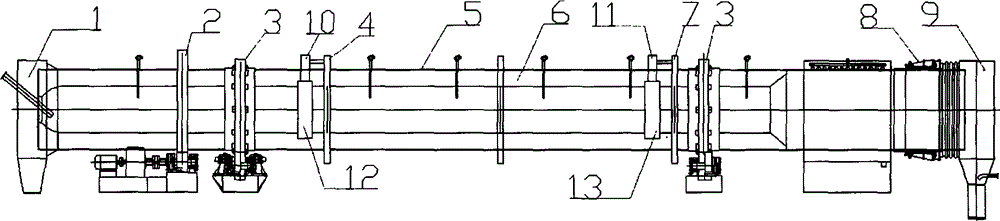

[0033] figure 2 It is the schematic diagram of Embodiment 2, an electric heating rotary kiln device, which is used for drying or heating materials, including a rotary tube 5, a rotary tube thermal insulation part 6, a pulley 2, a load-bearing wheel 3, a heating system, and a kiln head inlet. For components such as material 1 and kiln tail discharge material 9, the part of the inner layer of the thermal insulation part that contacts the material is an insulating material. The electrodes are composed of conductive materials 10, 11 and ring-shaped conductive materials 12 and 13 respectively conductively connected to them. The ring-shaped conductive materials 12 and 13 are fixed on the inner wall of the rotary kiln hearth, and they are in contact with the materials in the rotary kiln hearth during work. , the conductive materials 10 and 11 pass through the rotary tube and the thermal insulation part 6, and the conductive materials 12 and 13 are in contact with the materials in th...

Embodiment 3

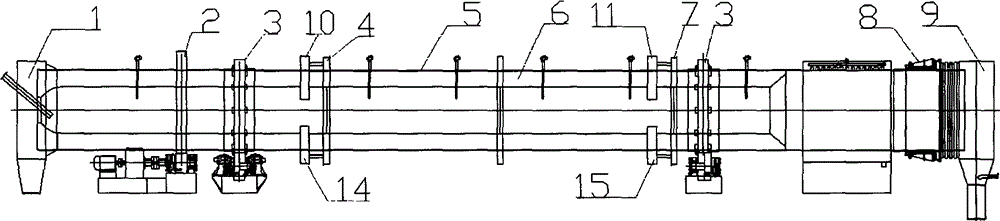

[0035] image 3 It is the schematic diagram of embodiment 3, an electric heating rotary kiln device, which is used for drying or heating materials, including a rotary tube 5, a rotary tube thermal insulation part 6, a pulley 2, a load-bearing wheel 3, a heating system, and a kiln head inlet. For components such as material 1 and kiln tail discharge material 9, the part of the inner layer of the thermal insulation part that contacts the material is an insulating material. The electrodes are composed of a set of positive electrodes 10 and 14, and a set of negative electrodes 11 and 15. These two sets of electrodes pass through the rotary tube and the thermal insulation part 6, and are in contact with the materials in the rotary kiln furnace during work. Conductive rings 4 and 7 are fixed on the circumference of the outer wall of the revolving tube and electrically connected to the electrode groups 10 and 14, 11 and 15 respectively, and the power supply is connected to the conduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com