A kind of production technology of mobile phone sticking film

A production process and mobile phone filming technology, which is applied in the direction of photo-engraving process, photo-engraving process exposure device, opto-mechanical equipment, etc. on the pattern surface. less waste, less die and die cutting process, better product results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

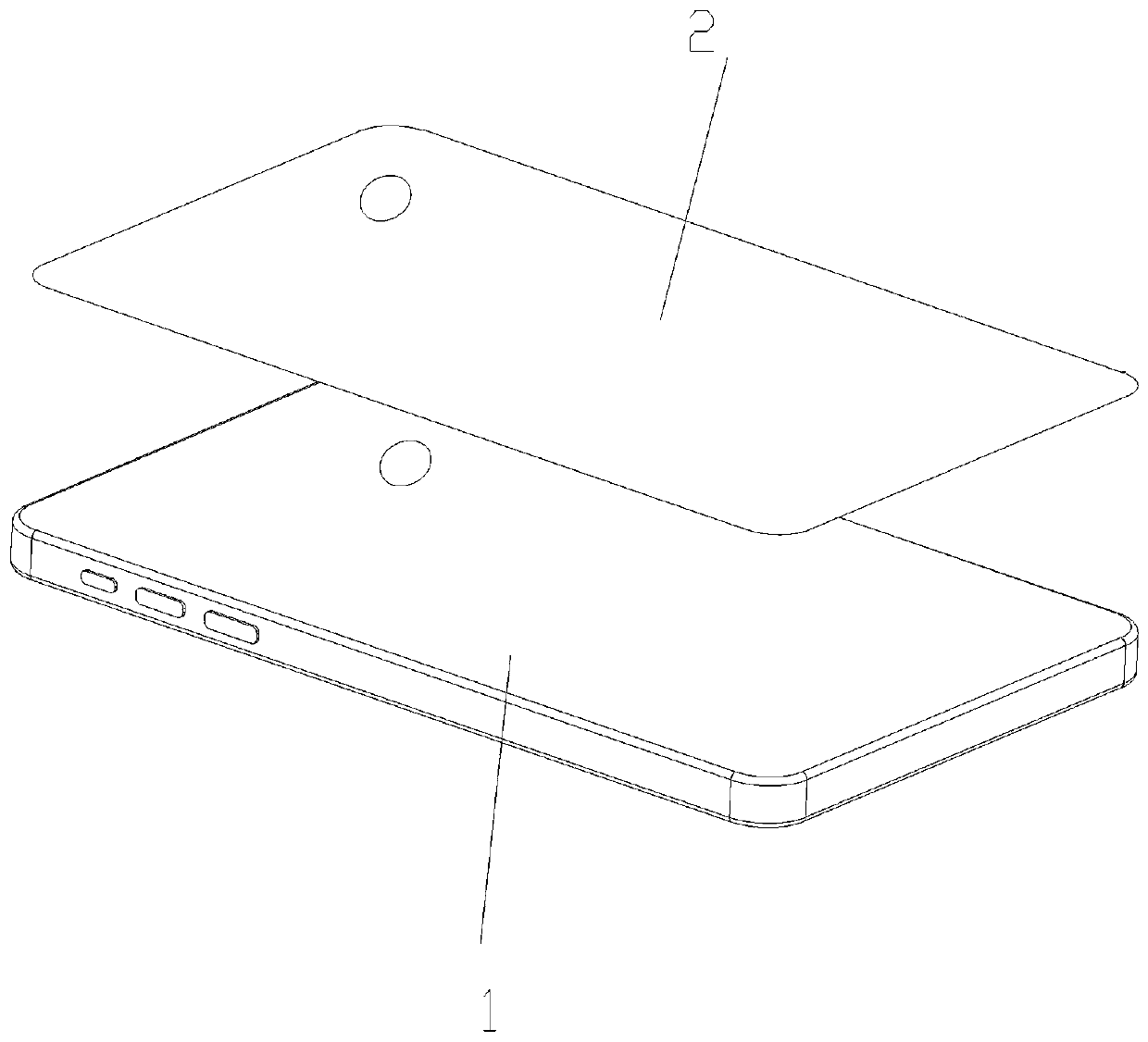

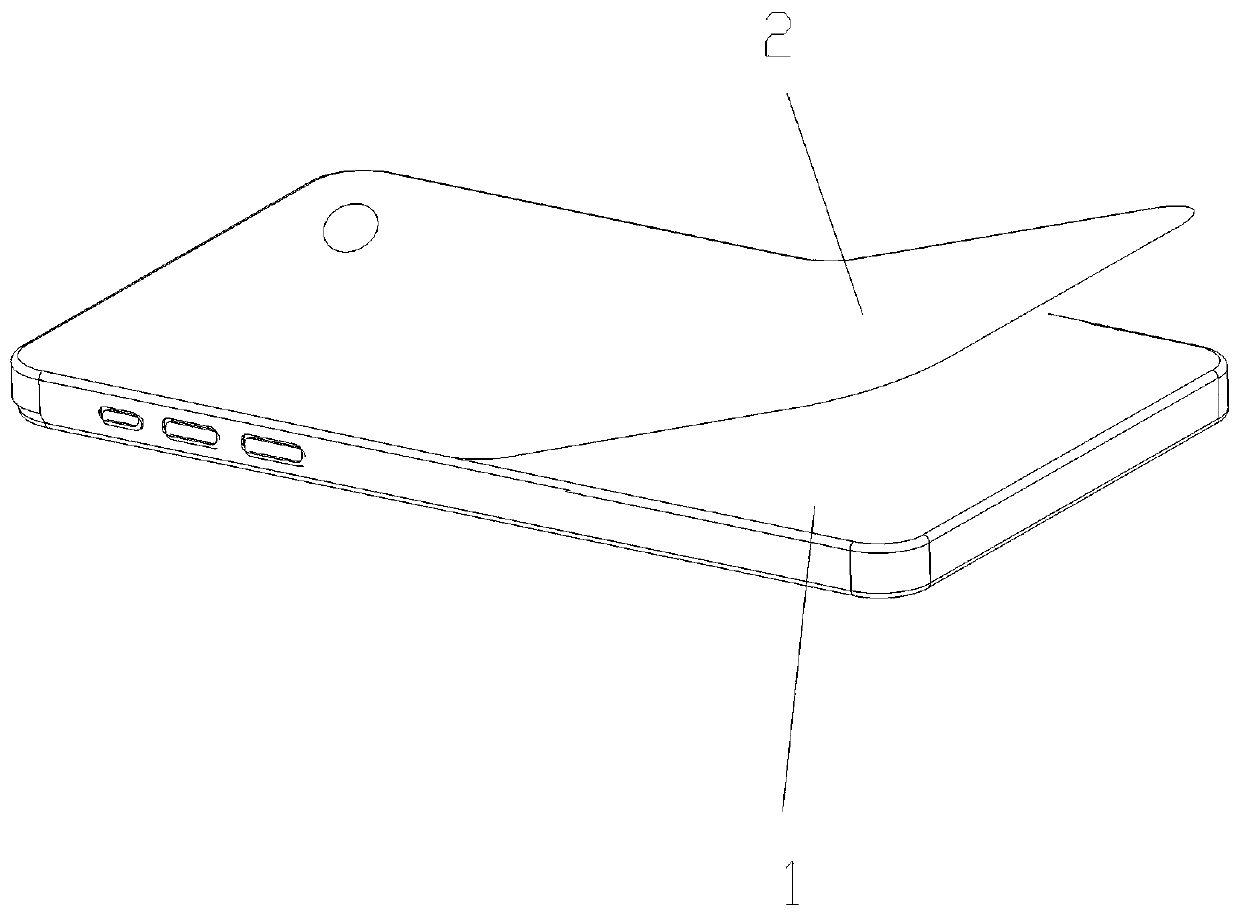

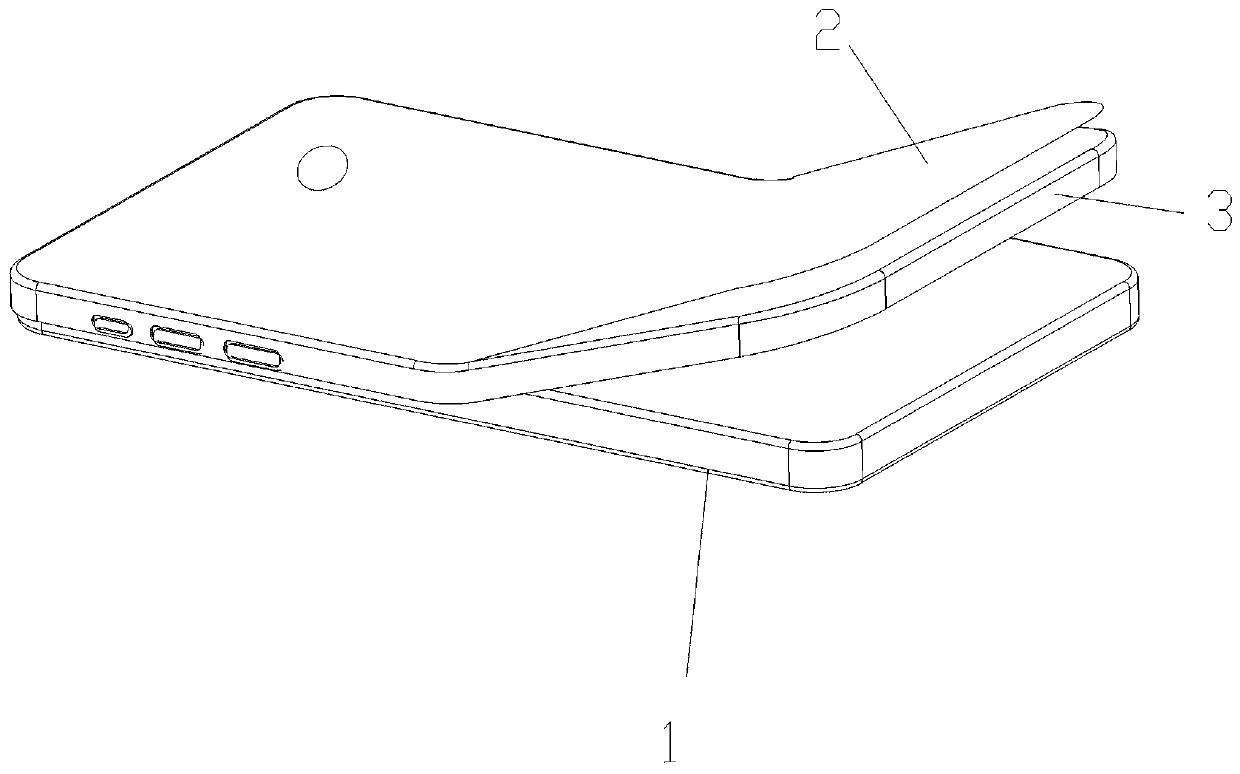

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and preferred specific embodiment to this 1. a kind of production technology of mobile phone sticking film, it is characterized in that: comprise the following steps

[0017] 1) According to the actual needs, take the steps of producing film and printing according to the model and size of the mobile phone;

[0018] 2) Spread the release paper, first print the self-adhesive on the release paper, and then print a certain thickness of UV oil on the self-adhesive;

[0019] 3) Dry the semi-finished products in the above steps;

[0020] 4) Carry out part or all of the required pattern printing bright gold bright silver oil process;

[0021] 5) Crop spare.

[0022] Of course, on the basis of the above, it is also possible to print the semi-finished product in color before the process of printing bright gold and silver oil in the above step 4), so that the film can be more beautified. In the step 3), UV drying is used for drying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com