Method and device for producing syngas by combustion and gasification of double cylinders

A technology of synthesis gas and double cylinders, which is used in fixed bed gasification, manufacture of combustible gas, chemical industry, etc., can solve the problems of many high temperature control components, large system heat loss, and high equipment failure rate, and achieves a small installation area. , convenient maintenance and management, high thermal efficiency of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing and specific embodiment the content of the present invention will be further described:

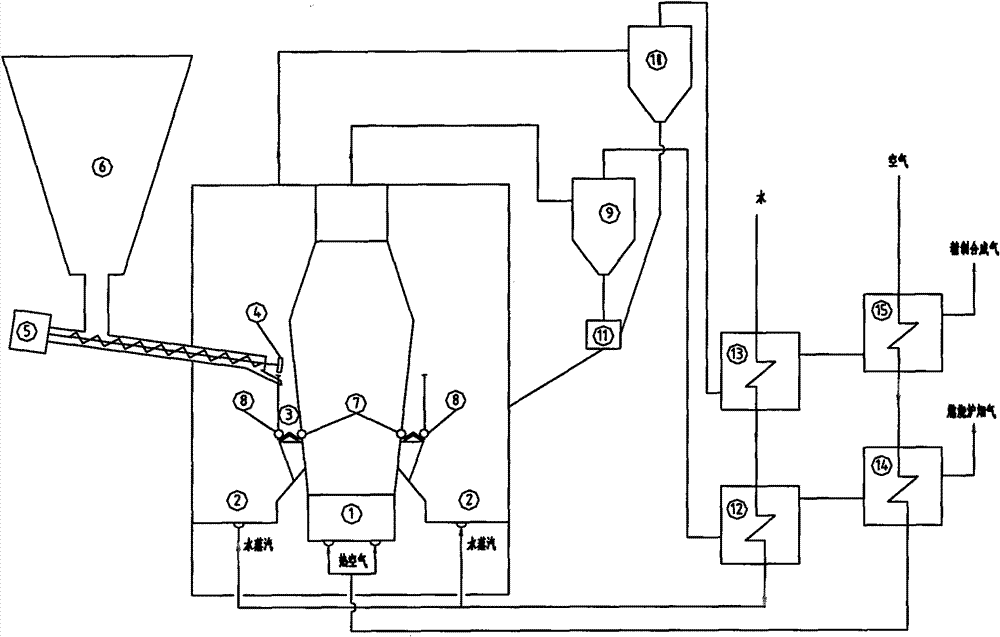

[0035] as attached figure 1 As shown, a method for producing syngas by double-cylinder combustion gasification, coal or biomass semi-coke products are sent from a hopper 6 through a feeder 5 to a turntable 3 installed in a gasifier 2, and the turntable 3 is fixed on The drive gear 4 on the feeder 5 is driven to rotate. During the rotation of the turntable 3, the material is thermally decomposed on the turntable 3 to release volatile gas. Transfer to the feed valve port 8 of each zone gasifier and enter the gasifier 2 . The material is thermally decomposed in the gasification furnace 2 and releases volatile gas. At the same time, under the action of the steam gasification agent, the carbon in the high-temperature material reacts to obtain a synthetic gas; the heat required in the reaction process is transferred from the combustion furn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com