Method for preparing catalyst with thermal-instability material carrier by using low-temperature plasma and application of catalyst

A technology of thermal instability and low-temperature plasma, applied in the fields of catalysis science and material science, can solve the problems of unrealized loading catalyst, cumbersome preparation process, and great environmental hazards, and achieve easy control of particle size, good catalytic activity, and particle size distribution The effect of narrow range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Will Cu 3 (BTC) 2 Loaded Pd(NO 3 ) 2 Put it between the two electrode plates of the discharge tube in the vacuum chamber, seal it tightly, evacuate the vacuum chamber, then fill it with argon as the discharge gas, maintain a pressure of 80Pa, apply a DC voltage of 500V to the electrodes, and use glow discharge plasma Bulk reduced Pd(N0 3 ) 2 , the reduction time is 60 min, and the nano-palladium particles are prepared, and the particle diameter is 2-3 nm.

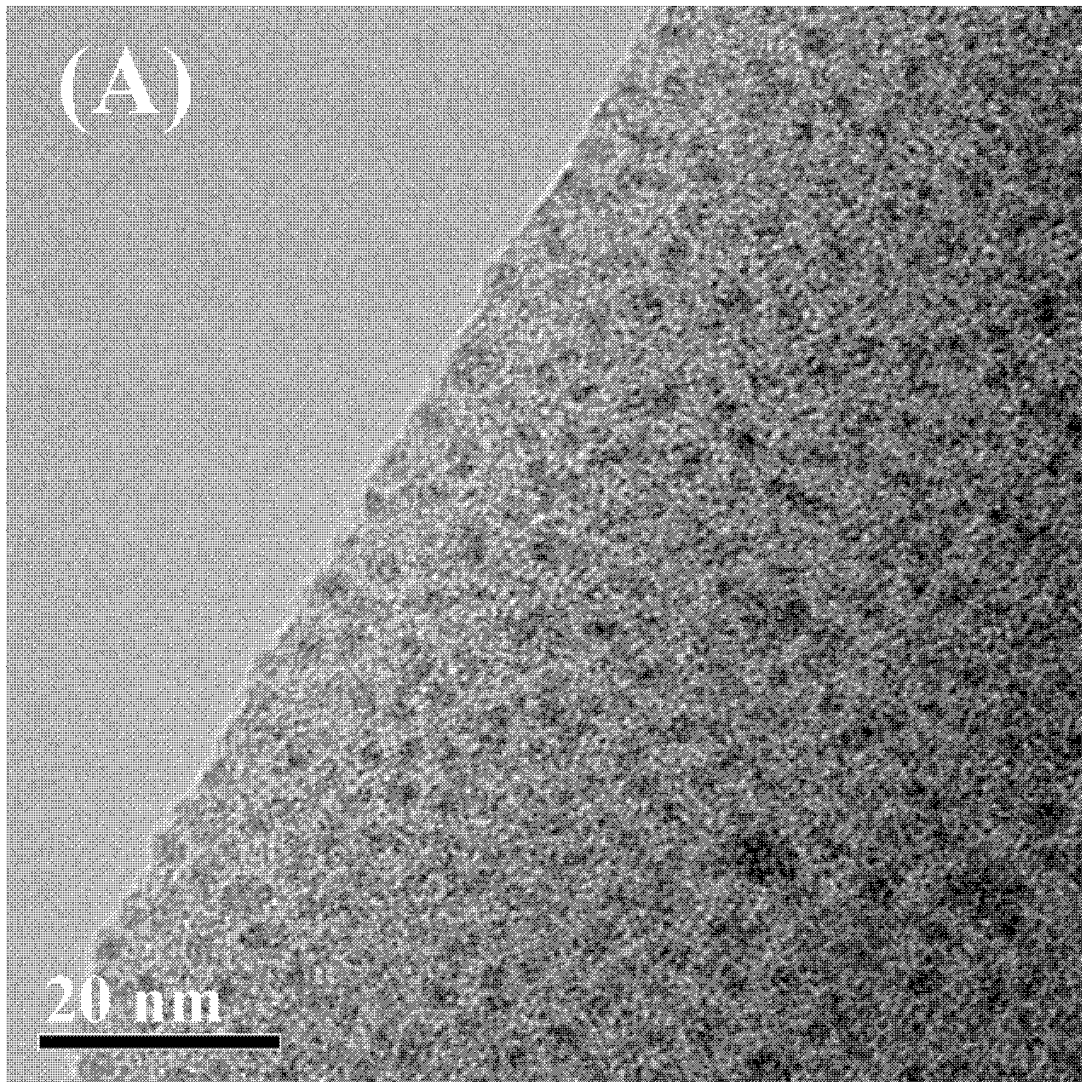

[0034] Cu produced 3 (BTC) 2 The supported nano-palladium particle catalyst is analyzed by electron diffraction, photoelectron spectroscopy, physical adsorption and transmission electron microscopy, and the following analysis results can be obtained:

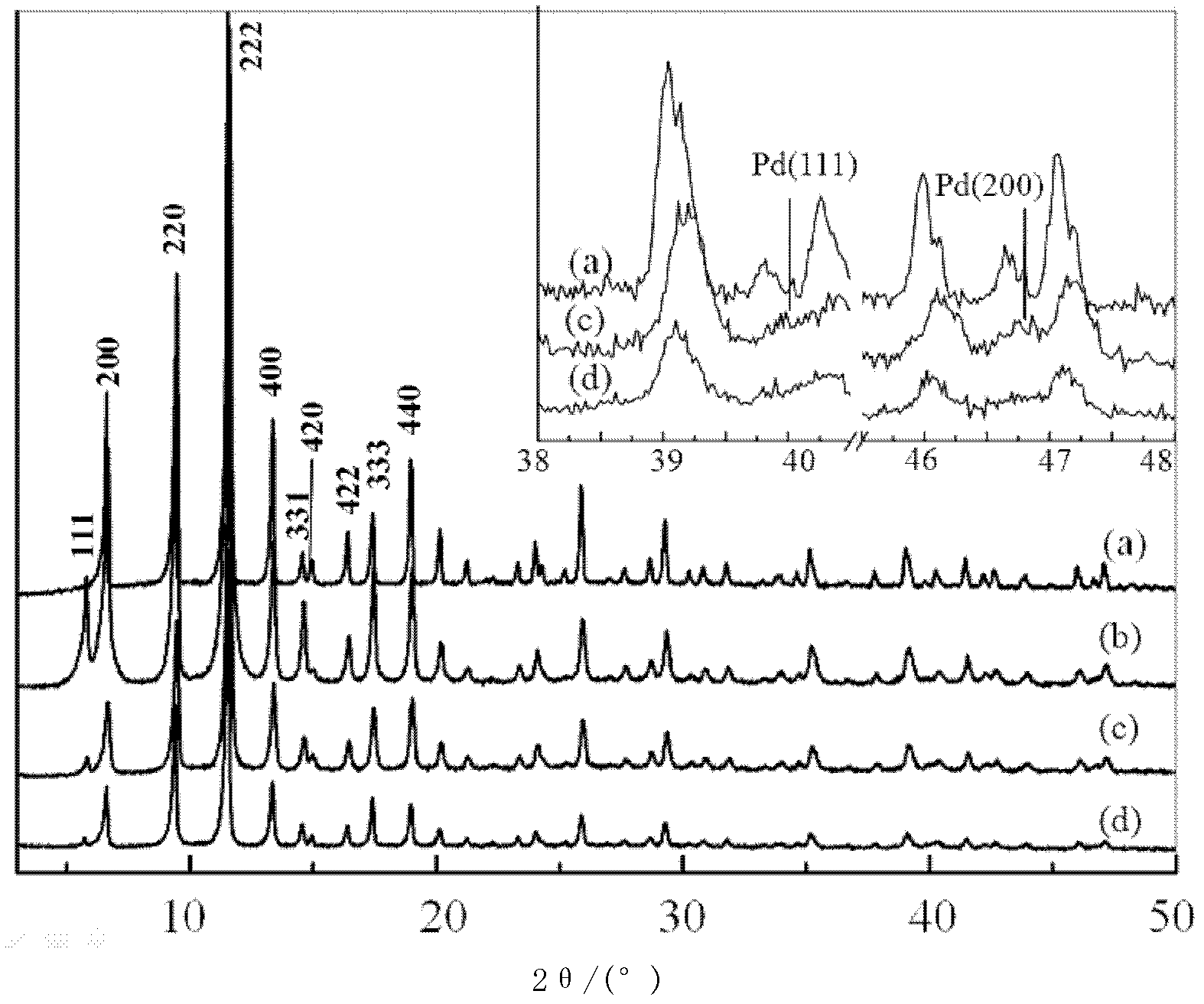

[0035] like figure 1 Shown electron diffraction pattern, only has the diffraction peak of palladium simple substance among the figure, shows that palladium nitrate is completely reduced;

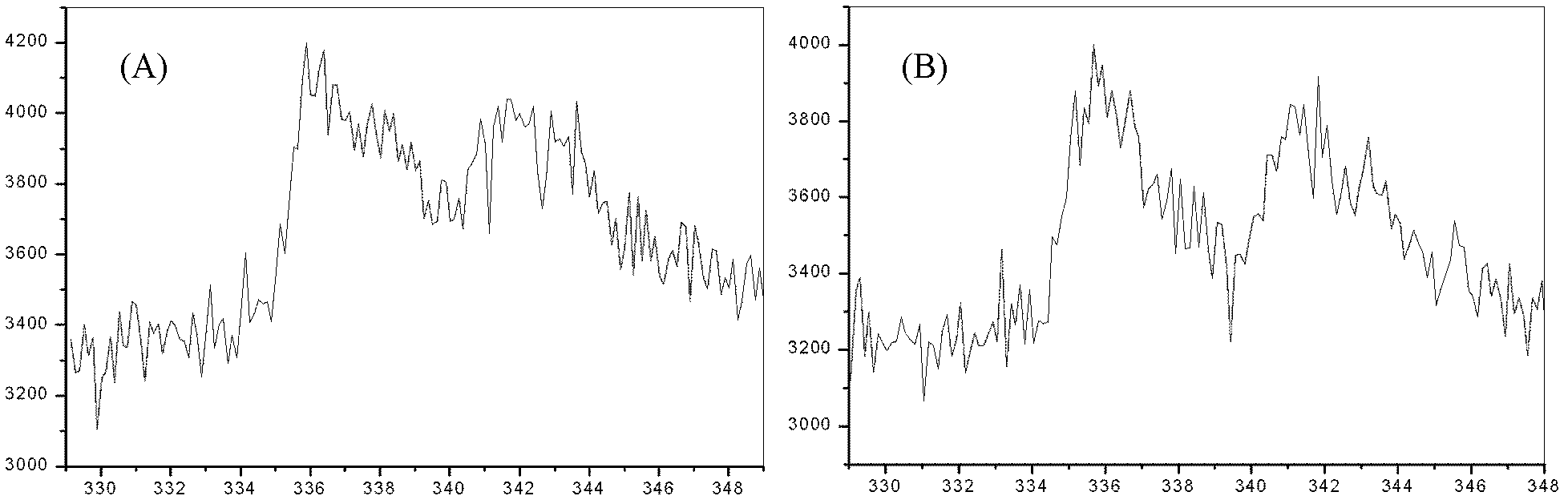

[0036] like figure 2 The photoelectron energy spectrogram shown can b...

Embodiment 2

[0043] Will Cu 3 (BTC) 2 Loaded AgNO 3 Put it between the two electrode plates of the discharge tube in the vacuum chamber, seal it tightly, evacuate the vacuum chamber, then fill it with nitrogen as the discharge gas, maintain a pressure of 120Pa, apply an AC voltage of 1500V on the electrode, and use glow discharge plasma reduced AgNO 3 , the reduction time is 80min, and the nano-silver particles are prepared. AgNO was confirmed by electron diffraction, photoelectron spectroscopy, physical adsorption and transmission electron microscopy 3 Completely reduced to simple silver, and evenly loaded on the carrier, the particle size is 4-20nm. This sample was used for CO oxidation with good results.

Embodiment 3

[0045] The MOF-177-loaded H 2 PtCl 6 Place it between the two electrode plates of the discharge tube in the vacuum chamber, seal it tightly, evacuate the vacuum chamber, then fill it with helium as the discharge gas, maintain a pressure of 80Pa, apply a DC voltage of 200V to the electrodes, and use glow discharge plasma reduced H 2 PtCl 6 , the reduction time is 120min, and nano-platinum particles are prepared. It was confirmed by electron diffraction, photoelectron spectroscopy, physical adsorption and transmission electron microscopy that H 2 PtCl 6 It is completely reduced to elemental platinum, and it is evenly loaded on the carrier, and its particle size is 3-10nm. This sample was used for CO oxidation with good results.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com