Production technology of steel wire ring for tires

A production process and technology of bead rings, which are applied in the fields of tire manufacturing and tire casing manufacturing, can solve the problems of increasing production cost of rubber materials, affecting tire quality, and low work efficiency, so as to improve the bonding of bead rings and reduce equipment Retrofit is difficult and the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

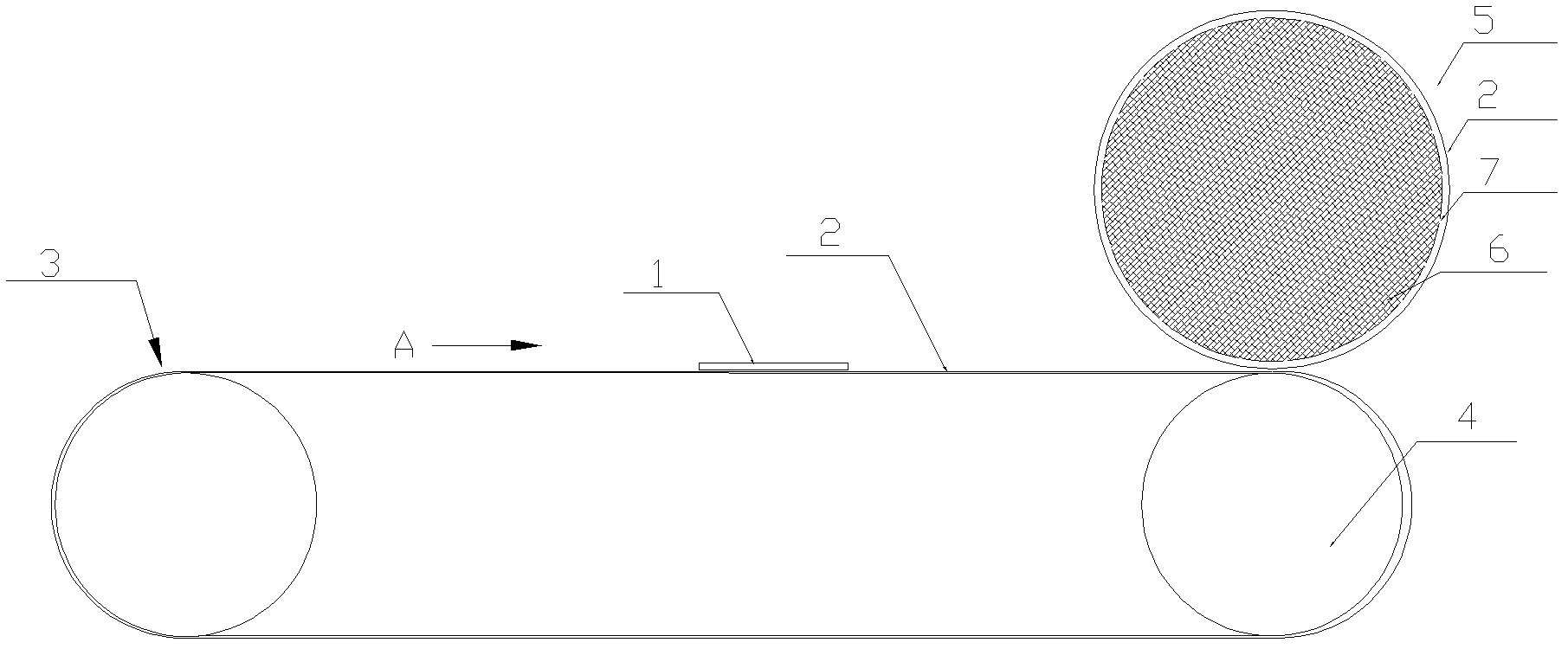

Image

Examples

Embodiment Construction

[0019] The present invention is further described below in conjunction with specific embodiment, and specific embodiment is the further description of the principle of the present invention, does not limit the present invention in any way, and the identical or similar technology of the present invention all does not exceed the scope of protection of the present invention.

[0020] The specific embodiments of the present invention will be further described below.

[0021] The production process of the tire traveler comprises the following steps:

[0022] a. Wire guide, b. Straightening, c. Wipe and clean, d. Electric preheating, e. Extrusion and coating, f. Cooling, g. Coil forming, h. Cutting, i. Covering with insulating powder.

[0023] Coating the spacer powder 6 is to coat the surface of the forming traveler 1 with the spacer powder 6 to prevent the traveler 1 from sticking after the rubber-coated molding.

[0024] The steel wire guide is to guide the steel wire coils curl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com