Laser inner hole cladding equipment and gravity powder feeder

A technology of gravity powder feeding and powder feeding device, which is applied in the coating process and coating of metal materials, can solve the problems of uneven powder feeding process, poor powder feeding stability, affecting the laser light path, etc. The powder is uniform and well combined

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0032] Laser cladding is a new type of surface modification technology that uses laser beams to heat the surface of cladding materials and substrates, so that the required special materials are welded to the surface of the workpiece. Laser inner hole cladding equipment is used for laser cladding processing of the inner hole surface of parts with large and deep inner holes such as cylinder blocks, hydraulic columns, and sleeve parts.

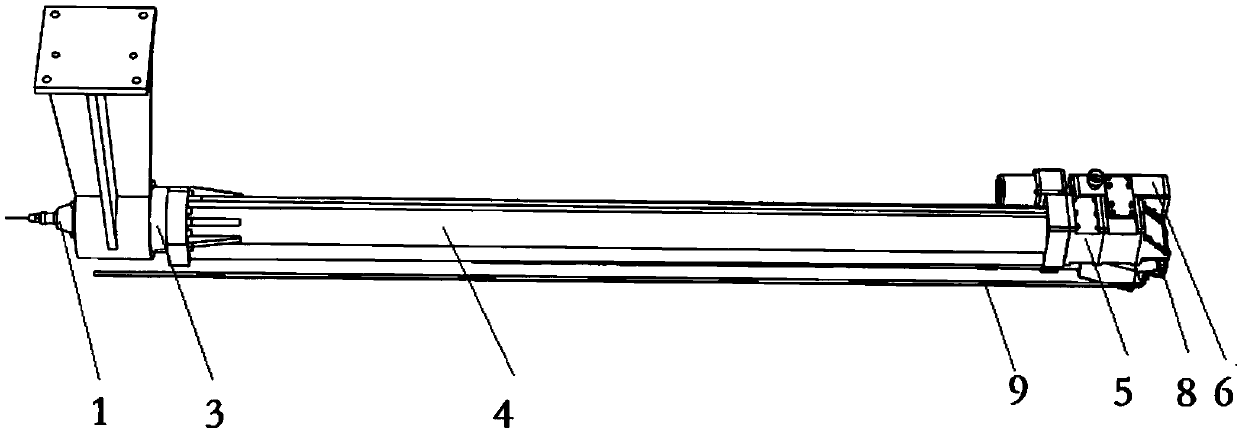

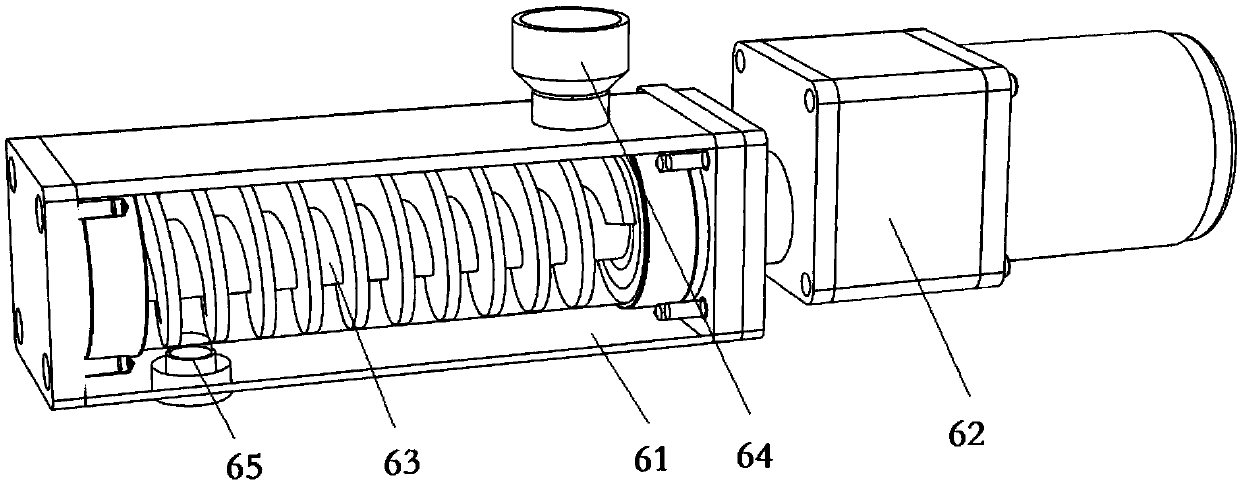

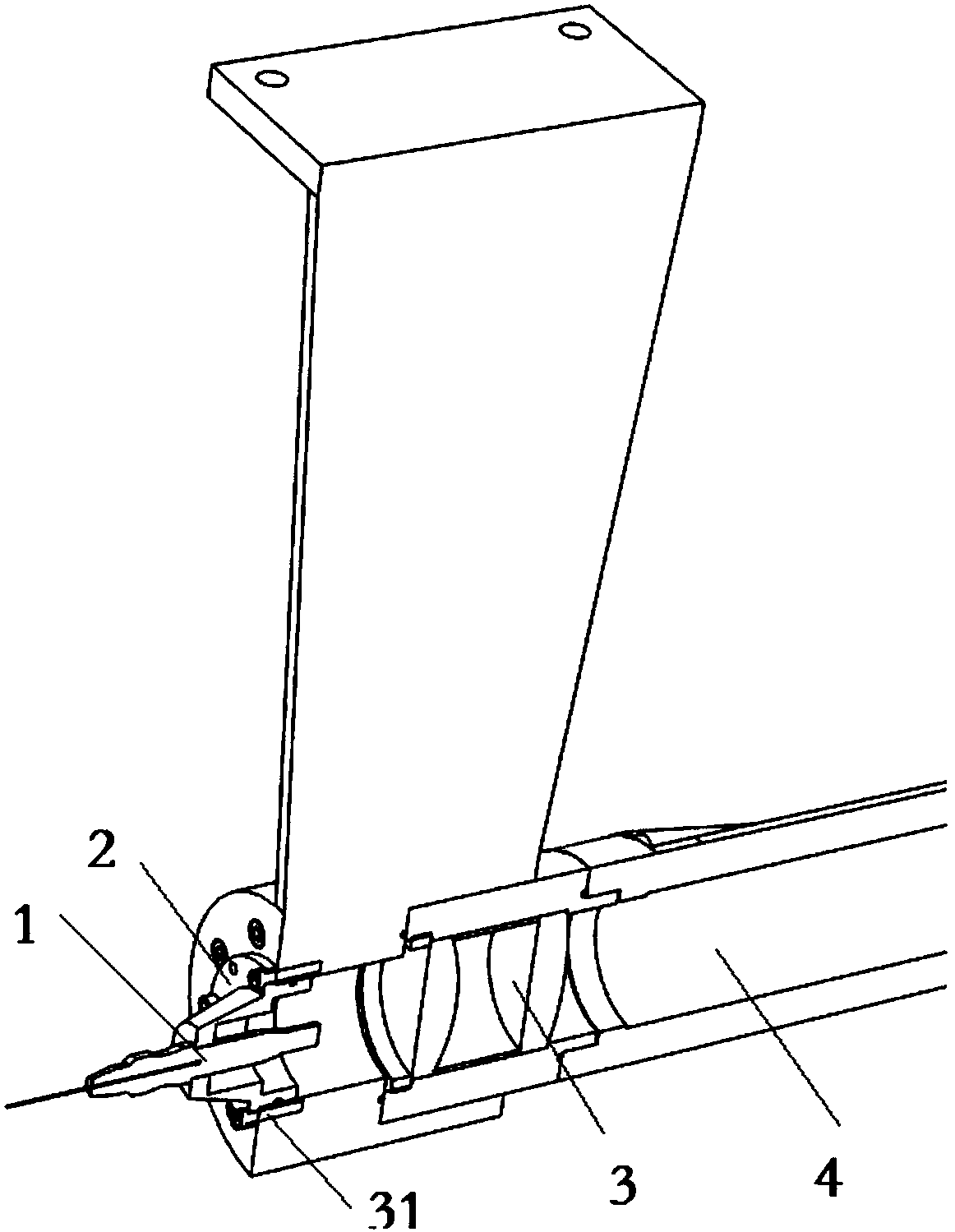

[0033] Such as Figure 1 to Figure 6 As shown, the laser inner hole cladding equipment includes an optical fiber head 1, a rear-end lens group 3, an intermediate connector 4, a front-end lens group 5, and a powder feeding assembly on the side of the front-end lens group 5; the powder feeding assembly includes a gravity The powder feeder 6 and the powder feeding nozzle 7, the gravity powde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com