Powder sprinkling device

A technology of powder spreading device and driving device, which is applied in textiles and papermaking, fiber raw material processing, papermaking, etc. It can solve the problems of large and difficult filler loss, and achieve the effect of uniform powder spreading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

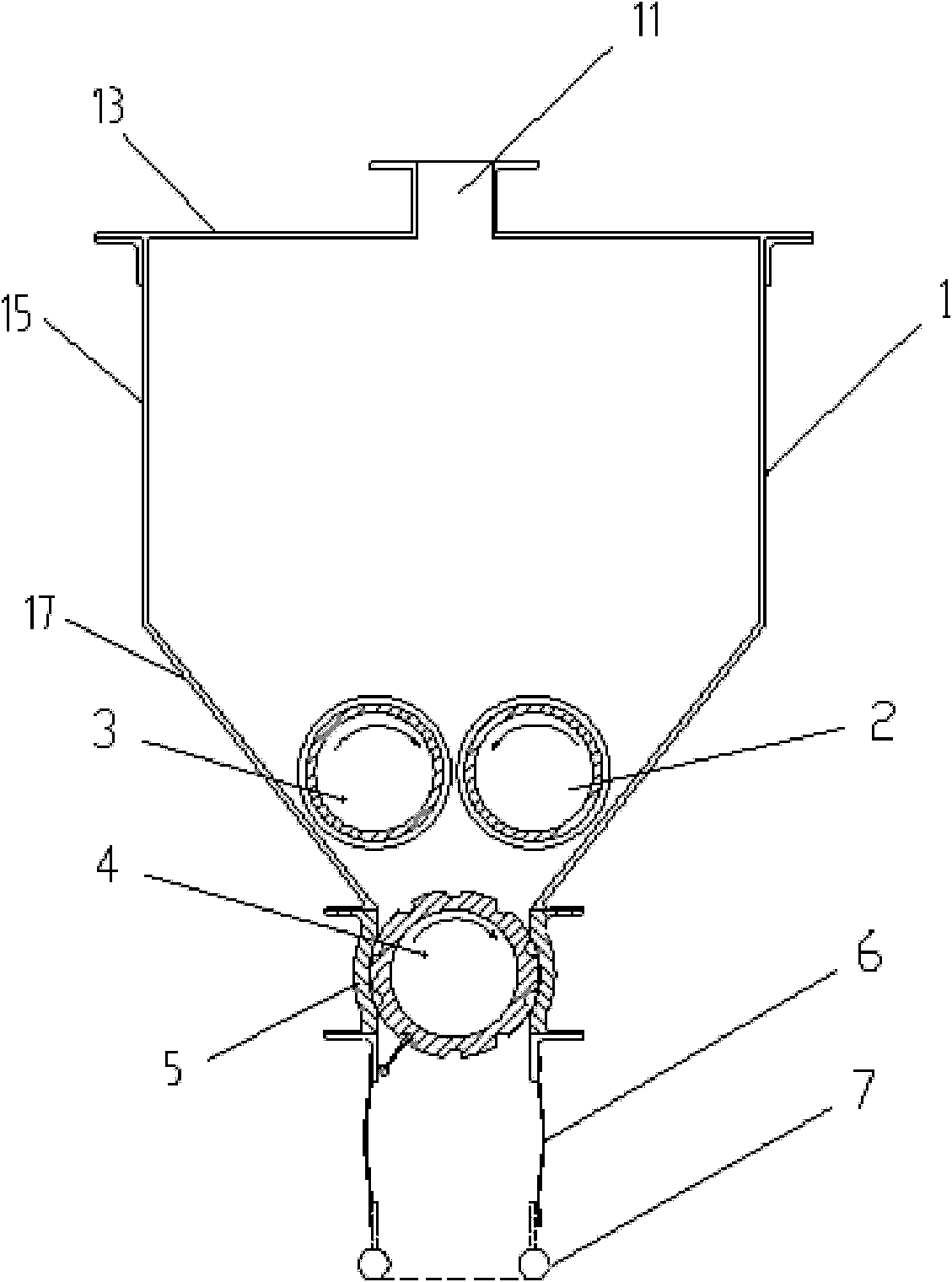

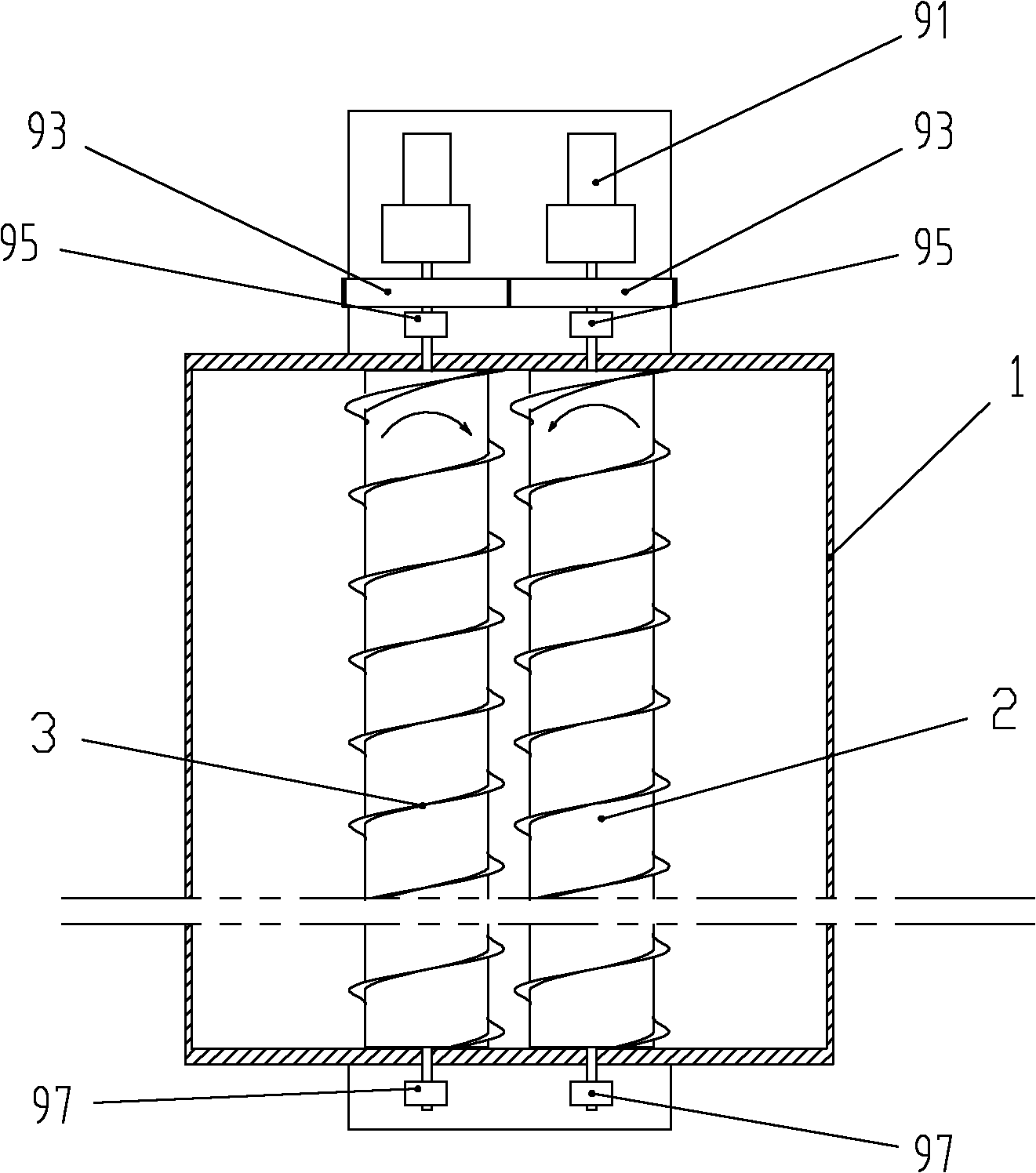

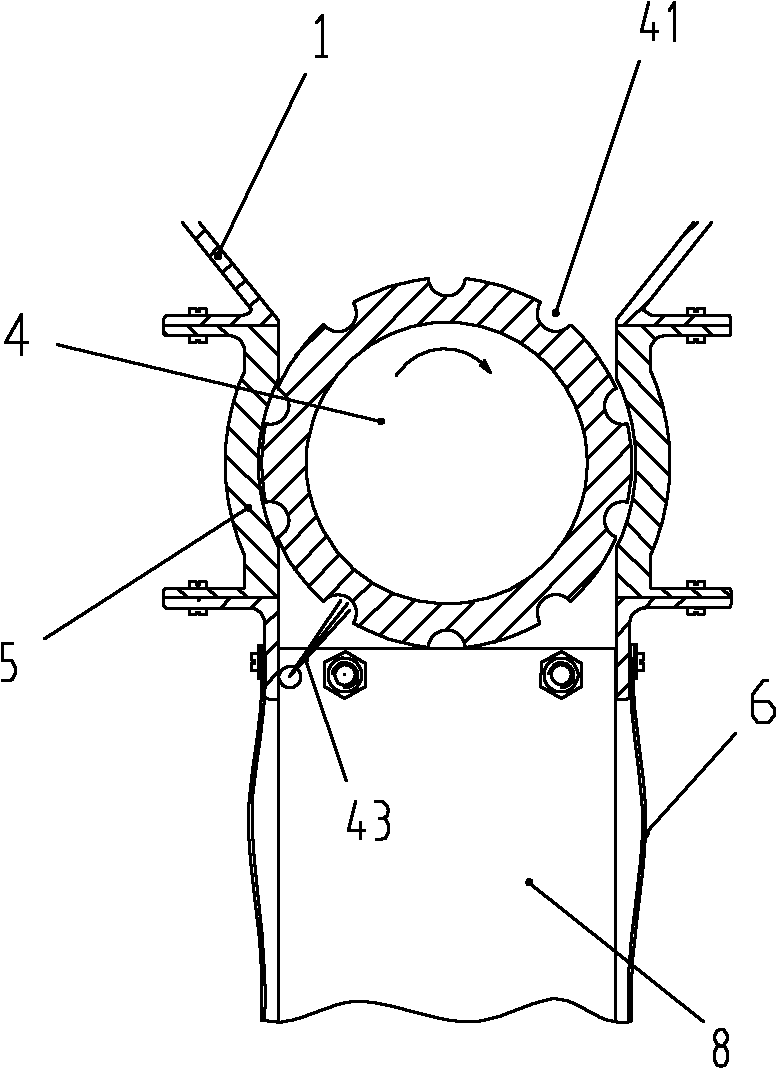

[0010] [Specific implementation] The powder spreading device of the present invention will be described in detail below in conjunction with the accompanying drawings: please refer to figure 1 As shown, the powder spreading device of the present invention mainly includes a powder hopper 1, leveling rollers 2 and 3 placed side by side at the lower end of the powder hopper 1, a housing 5 connected and fixed to the lower end of the powder hopper 1, and placed inside the housing 5. And the metering roller 4 in contact with the inner surface of the housing 5 , the connecting hose 6 fixedly connected to the lower end of the housing 5 , and the vibrating screen 7 connected with the connecting hose 6 and placed directly below the metering roller 4 .

[0011] read on figure 1 , and combined with figure 2 As shown, the powder hopper 1 is made of steel plate and has a bucket-shaped structure. It is divided into an upper part 15 and a lower part 17 according to the size of the cross-sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com