Powder spreading device

A technology of dusting device and powder box, which is applied in cleaning device, packaging, loading/unloading, etc., can solve the problems of powder retention and uneven dusting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

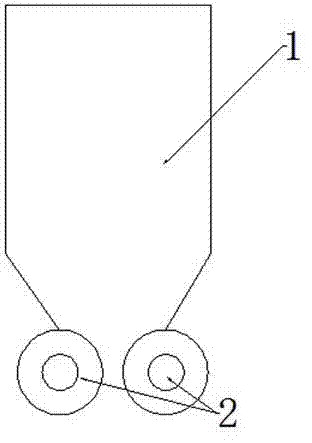

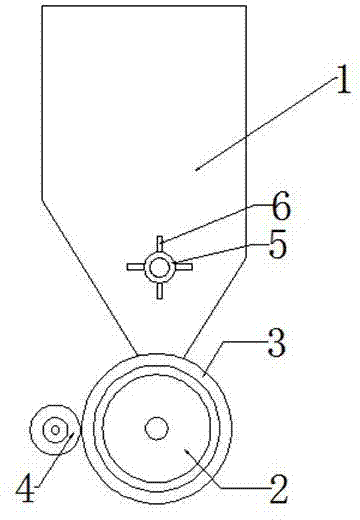

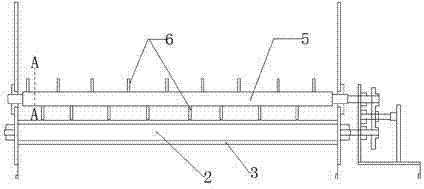

[0022] The powder spreading device includes: a powder filling box 1, a powder spreading roller 2 placed at the outlet of the lower end of the powder filling box 1, a powder clamping part 3 wrapped on the outside of the powder spreading roller 2 and used to carry powder, and used in combination with the powder spreading roller 2 The cleaning member 4 is used to sweep the powder on the surface of the powder spreading roller 2; as a preference, the cleaning member 4 is a brush. The cleaning member 4 can also be other objects capable of sweeping the powder such as a scraper; as a preference, the powder is epoxy resin powder.

[0023] The powder card 3 is a cotton cloth wrapped on the outside of the powder spreading roller 2. According to the characteristics of the epoxy resin powder, as a preference, the cotton cloth is an elastic card clothi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com