Adjustable air and powder mixer

A mixer and air conditioning technology, applied in the preparation of block/powder fuel, combustion method, combustion equipment, etc., can solve the problems of unevenness, affecting the amount of powder, and affecting the pressure at the powder pipe.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Best practice:

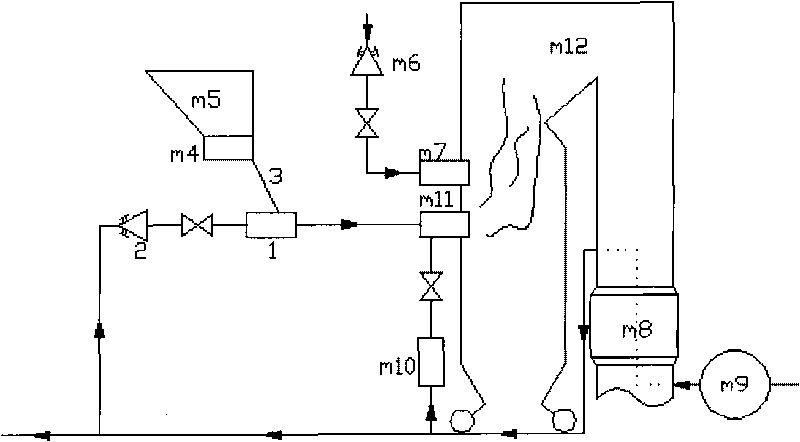

[0025] Refer to attached figure 1 , the components in the figure are: 1. Mixing cavity, 2. Primary air box, 3. Powder lower pipe, m4, powder feeder, m5, powder storage bin, m6, tertiary air box, m7, tertiary air nozzle, (for larger There is usually no valve between m6 and m7, which is not important in this project) m8, air preheater, m9, blower, m10, secondary air box, m11, burner, m12, boiler. The direction of the arrow in the figure is the wind flow direction.

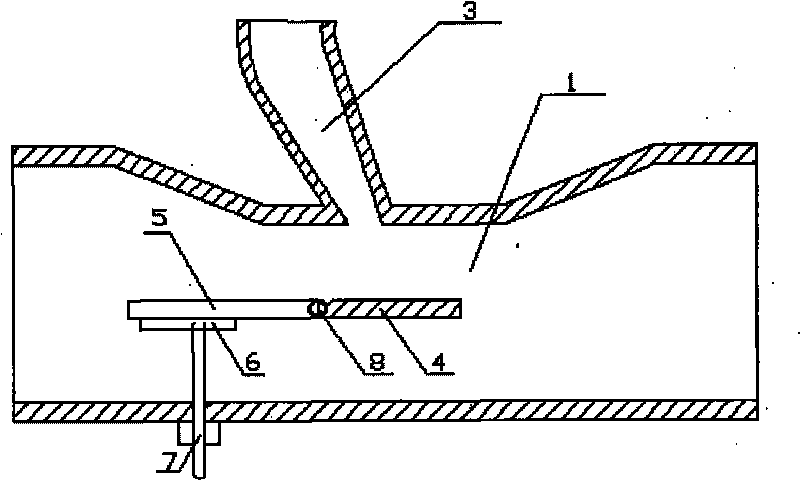

[0026] Refer to attached figure 2 , combined with the attached figure 1 , adjustable air powder mixer, including mixing cavity 1, bellows 2 (that is, attached figure 1 The primary wind box in the middle) and the lower powder pipe 3, the inlet of the mixing chamber 1 is communicated and connected with the air box 2, and the outlet of the mixing chamber 1 is communicated and connected with the burner. The mixing chamber 1 is a horizontal cylindrical cylinder with an upward opening, which i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com