Surface test method based on atomic scattering

A surface testing and atomic technology, applied in measurement devices, instruments, scanning probe microscopy, etc., can solve problems such as affecting beam current characteristics, cumbersome steps, affecting experimental progress, etc., to change the beam spot size and increase the range. , Simple operation and time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

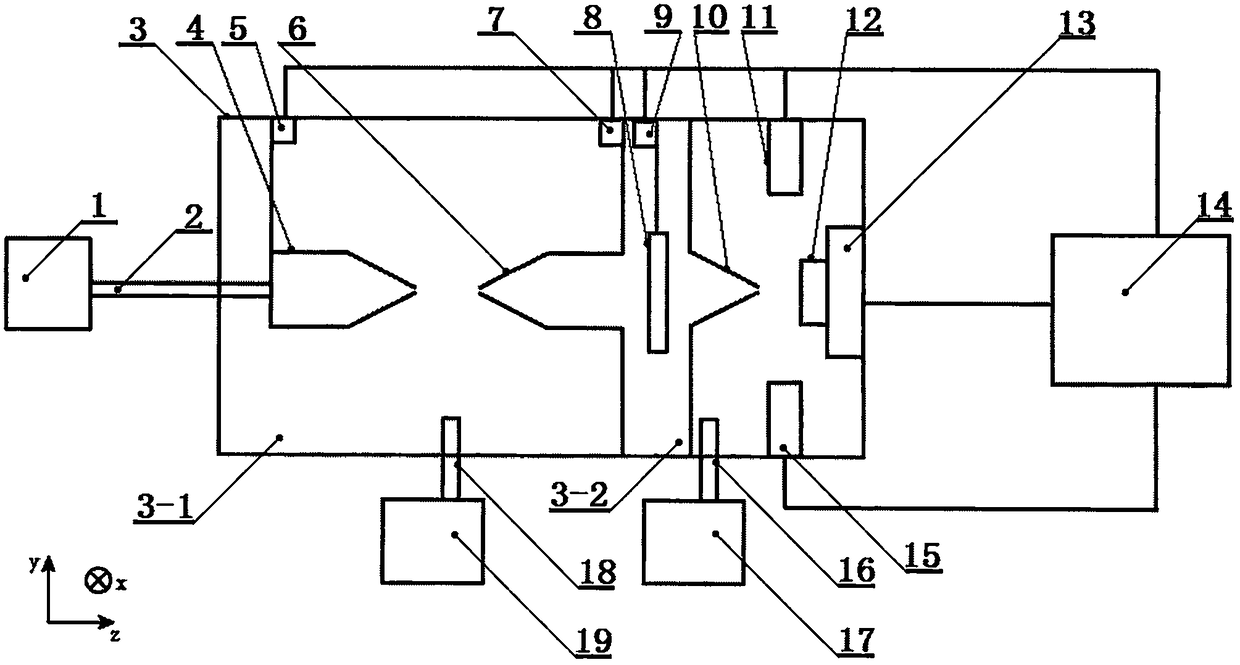

[0023] Such as figure 1It is a schematic diagram of the surface testing device based on atomic scattering in the present invention. The surface testing device based on atomic scattering mainly includes a gas storage tank (1), a gas pipe (2), a cavity I (3-1) and a cavity II (3-2 ) connected to form a vacuum chamber (3), injection head (4), driver I (5), shunt (6), driver II (7), collimating aperture array (8), translation stage (9), main Aperture (10), detector I (11), sample (12), sample stage (13), computer (14), detector II (15), suction port I (16), vacuum pump group I (17), suction Gas port II (18), vacuum pump group II (19), xyz is a three-dimensional coordinate system, and the z-axis is a horizontal direction. The cavity I (3-1) and cavity II (3-2) pass through the flow divider (6) Connection, the cavity II (3-2) is connected to the vacuum pump group I (17) through the suction port I (16), and the cavity I (3-1) is connected to the vacuum pump group II (19) through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com