Composite core-spun yarn and large-line-energy welding steel preparing method

A technology of high-energy welding and cored wire, which is applied in the field of iron and steel metallurgy, can solve the problems of increased smelting cost, high cost, and added price, and achieve the effects of improving the stability of the smelting process, reducing the number of times of alloy feeding, and simplifying the production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

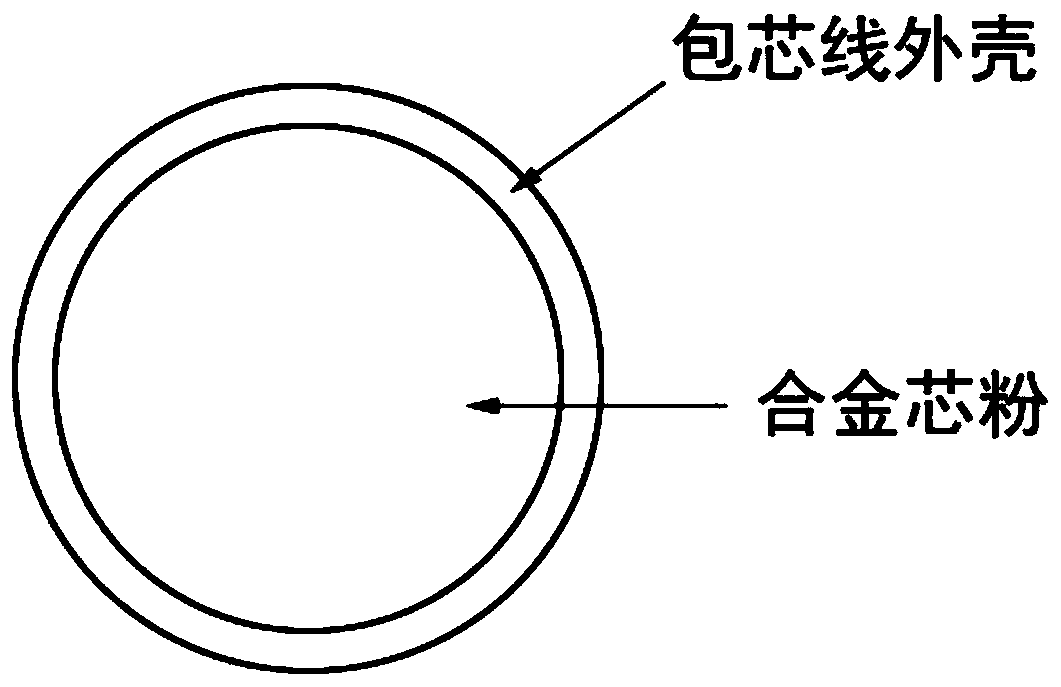

[0039] This embodiment is to prepare the Ti-containing composite cored wire used for large input energy welding EH36 shipbuilding steel plate, such as figure 1 As shown, the composite cored wire is composed of a tubular cored wire shell and an alloy core powder filled in the tubular shell. The chemical composition of the core powder is (wt.%): Si 18.00%, Ti 25.00%, Mn 2.00% , Al 6.00%, P≤0.025%, S≤0.025%, auxiliary element 25.00%, the rest is Fe and unavoidable impurities.

[0040] Wherein the additive elements are at least two of Mg, Ca, Zr and RE; among the additive elements, Mg is 0-15%, Ca or / and Zr is 5-20%, and RE (Ce or La) is 1-20%. 10%.

[0041] Prepare the raw material powder according to the composition of the above alloy core powder, the particle size of the raw material powder is ≤3mm, mix the raw material powders according to the ratio of the core powder, and after mixing evenly through the powder mixer, use the SPCC cold-rolled mild steel strip with a thickness...

Embodiment 2

[0043] This embodiment is to prepare the Ti-free composite cored wire used for large input energy welding EH36 shipbuilding steel plate, such as figure 1 As shown, the composite cored wire is composed of a tubular cored wire shell and an alloy core powder filled in the tubular shell. The chemical composition of the core powder is (wt.%): Si 38.00%, Mn 1.00%, Al 1.50% , P≤0.025%, S≤0.025%, additive elements 23.00%, and the rest are Fe and unavoidable impurities.

[0044] Wherein the additive elements are at least two of Mg, Ca, Zr and RE; among the additive elements, Mg is 0-15%, Ca or / and Zr is 5-20%, and RE (Ce or La) is 1-20%. 10%.

[0045] Prepare the raw material powder according to the composition of the above alloy core powder, the particle size of the raw material powder is ≤3mm, mix the raw material powders according to the ratio of the core powder, and after mixing evenly through the powder mixer, use the SPCC cold-rolled mild steel strip with a thickness of 0.55mm a...

Embodiment 3

[0047] Utilizing the Ti-containing composite cored wire prepared in Example 1 to prepare the EH36 shipbuilding steel plate for large heat input welding, the process is as follows:

[0048] Using 120 tons of converter smelting-LF ladle furnace refining-VD vacuum refining-continuous casting process to make continuous casting slabs with a thickness of 260mm. The chemical composition of the slab contains C 0.09%, Si 0.23%, Mn 1.58%, Ti 0.02%, Al 0.021%, Ca 0.0015%, Ce 0.0013%, Zr 0.003%, Mg 0.0035%, P 0.008%, S 0.002%, the rest is Fe.

[0049] In the above smelting process, when the molten steel reaches the LF ladle furnace for refining, the temperature of the molten steel is controlled to reach 1560°C±10°C, and when the oxygen content of the molten steel is controlled to reach 50ppm by adding ferromanganese and ferrosilicon, it is fed at a feeding speed of 250m / min. Enter 380 meters of Ti-containing composite cored wire prepared in Example 1. After the wire feeding finishes, blo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com