Harvester header device with multiple obliquely-arranged disc-shaped cutters and harvesting method

A harvester and multi-disc technology, which is applied in the direction of the harvesting table, harvester, agricultural machinery and implements, etc., can solve the problems that the harvesting cannot be carried out smoothly, the stalks fall to the front, the front is blocked, etc., and achieves simple structure, cutting And the effect of reliable conveying and reducing jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described with reference to the drawings and examples below.

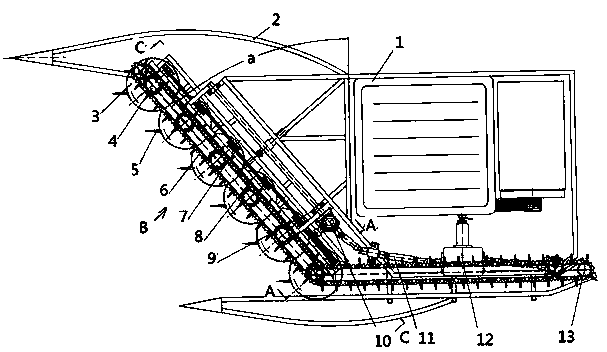

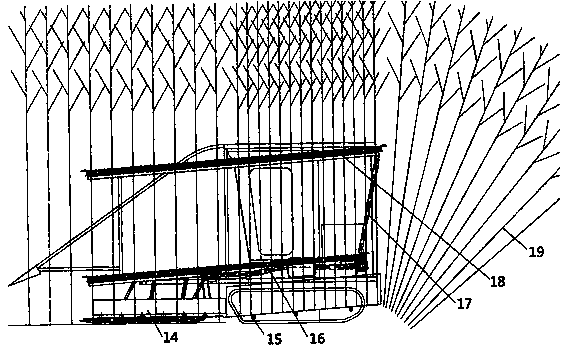

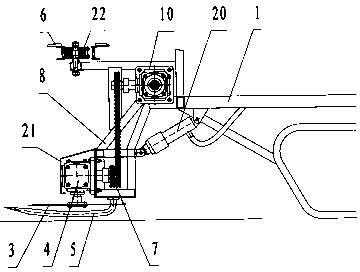

[0036] Accompanying drawing has provided an embodiment of the present invention, can find out by accompanying drawing, the present invention relates to a kind of harvester header device that multi-disc cutter is arranged obliquely, comprises header frame, disc cutter, Transmission device and conveying device, the header frame is installed on the harvester chassis, the disc cutter is installed on the header frame, and the disc cutter is driven by the power device on the harvester chassis through the transmission mechanism, its characteristics In that: the disc cutter is composed of more than two disc cutters to form a disc cutter combination, and all the disc cutter cutters of the disc cutter combination are arranged obliquely relative to the horizontal direction of the harvester. Arrangement; at the same time, a conveyor chain with shifting teeth is provided on the cutte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com