Standing grain pull chain type corncob-pickup straw-collecting stubble-cutting returning-type corncob and stem concurrent-harvesting header

A technology of corn cobs and headers, which is applied in the direction of headers, cutters, harvesters, etc., can solve the problems of blockage power consumption, inability to adapt to different corn planting specifications, and increase operating costs, so as to improve picking and supporting capabilities, Effects of Improving Maize Harvesting Efficiency and Increasing Row Spacing Adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the embodiments given by the accompanying drawings.

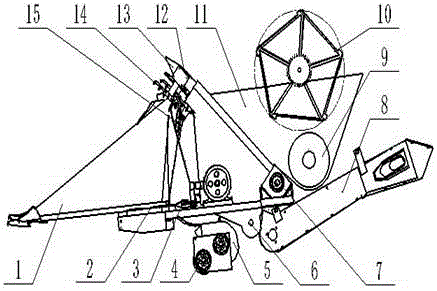

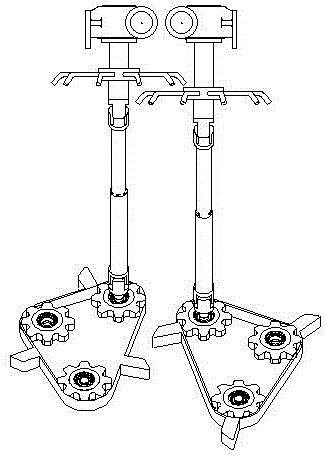

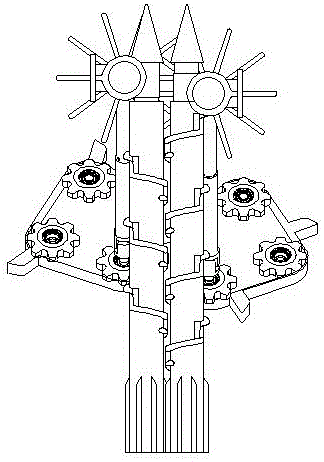

[0016] A reeling chain-type corn cob and stem harvesting platform for breaking ears, collecting stalks, cutting stubble and returning to the field, including an integrated device for reeling and pulling stems and breaking ears, an ear collection device, a stalk collection and recovery device, a device for cutting stubble and returning to the field, and a frame ( 11), characterized in that: the integrated device for reeling, pulling stems and breaking ears includes a grain divider (1), a reel chain (2), a worm gear reducer (12), a reel (14), and a cutter (3) , a universal joint (15) and a stem pulling roller (13), which is located at the forefront of the header; the stalk collecting device includes a stalk pulling wheel (10) and a stalk collecting auger (9), which is placed on the stem pulling Above the ear breaking integrated device; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com