Millet combined harvester and system thereof

A combine harvester and millet technology, applied in the field of crop harvesting, can solve the problems of cleaning loss and impurity content, and achieve the effect of low broken rate, impurity content and loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The technical solutions in the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the present invention.

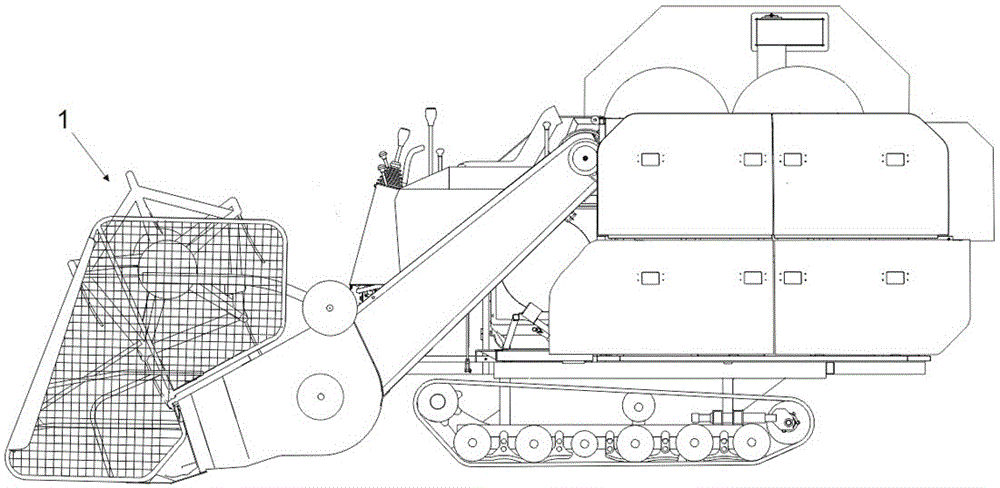

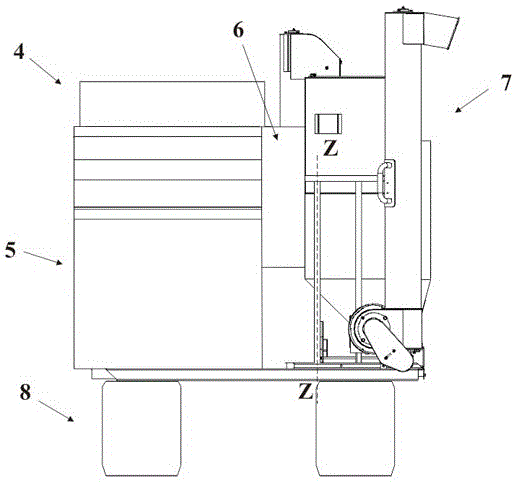

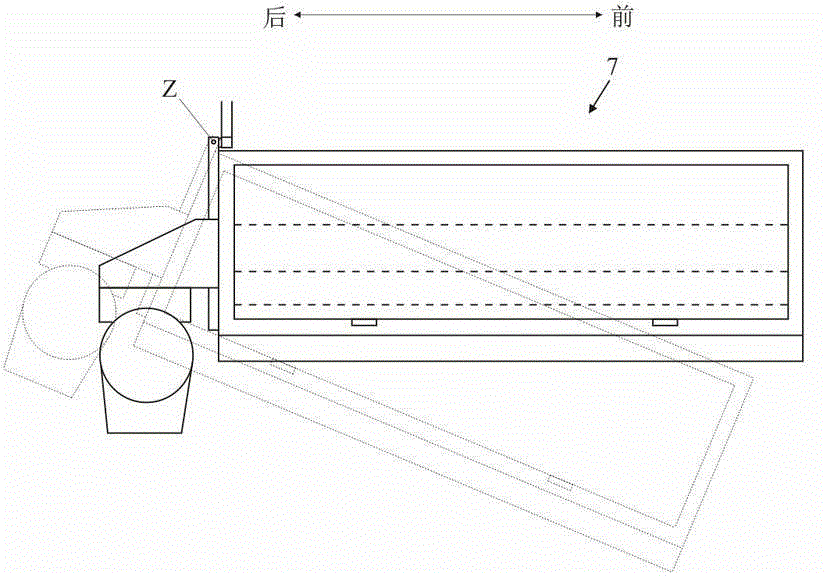

[0063] figure 1 , figure 2 It is the layout diagram of the whole machine according to the embodiment of the present invention, including the harvesting platform 1, the feeding and conveying part 3, the threshing and separating part 4, the grain cleaning part 5, the crushing and discharging part 6, the grain collecting and unloading part 7, and the chassis walking part 8 . The front of the chassis walking part 8 is provided with a header 1, and the rear part of the header 1 is fixedly connected to the left in the middle of the feeding conveyance part 3. For the convenience of dismounting, the replacement of the pick-up platform adopts a bolted connection. The rear left side of the chassis running part 8 is provided with a threshing and separating part 4 and a grain cleaning part 5 in an upper and lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com