Automatic cutting type tea harvester cutting bench automatic levelling method and device

An automatic cutting and automatic leveling technology, applied in the direction of picking machines, harvesting platforms, harvesters, etc., can solve the problem of lack of picking surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

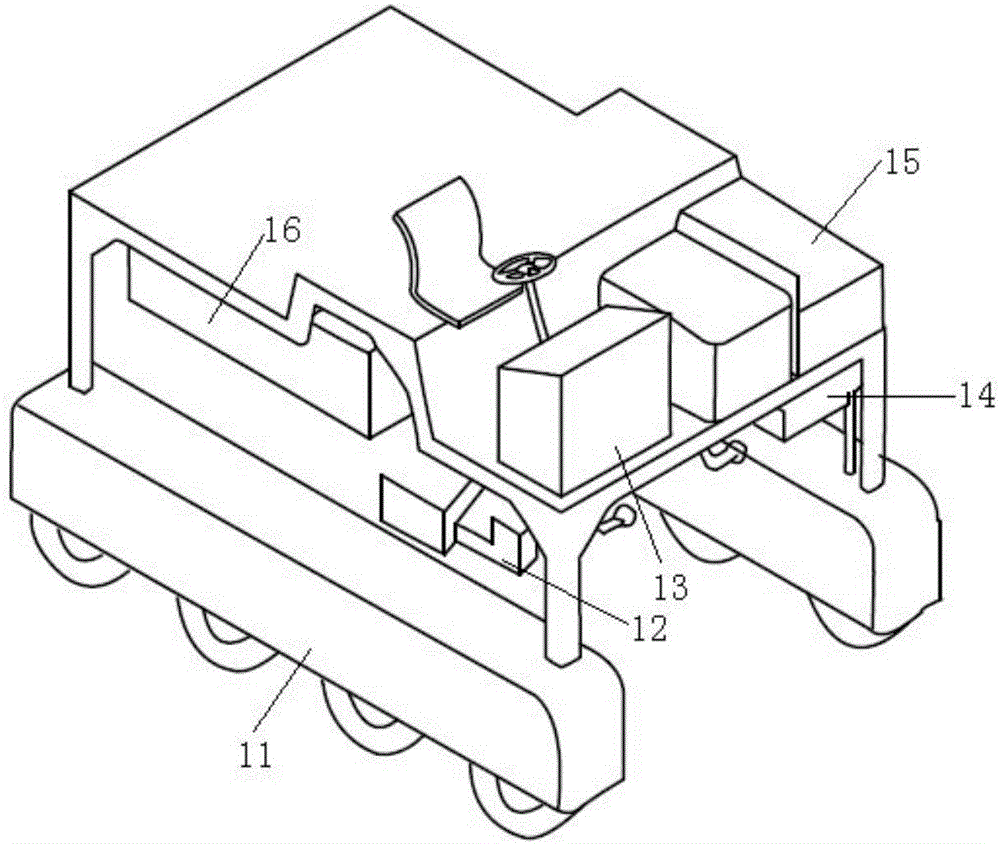

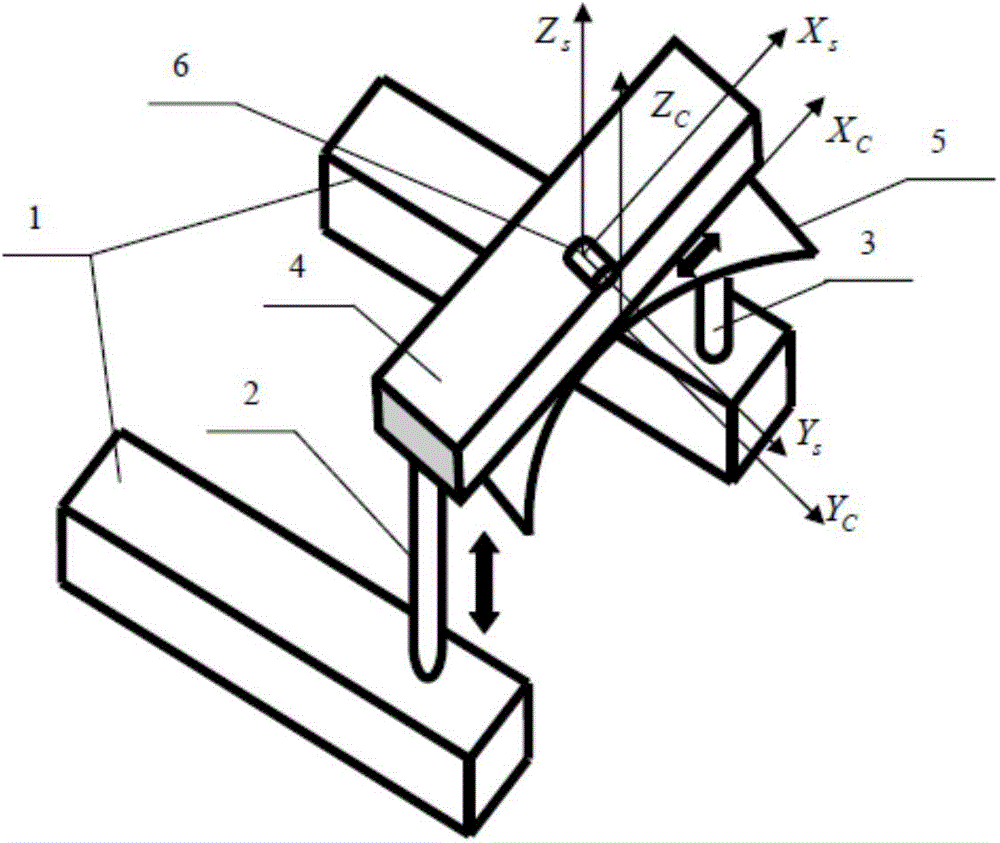

[0081] refer to Figure 1-8 , an intelligent automatic cutting type tea picking machine header automatic leveling device, used to improve the integrity and consistency of tea shoot picking, improve the overall quality and picking efficiency of tea, a standardized tea agronomic technology is used in the present invention; The machine-picked surface of the tea canopy is shaped and trimmed by the tea picking machine, so that the canopy of the tea canopy of each row of tea trees in the entire tea garden is shaped into a uniform arc-shaped canopy. Standardized tea agronomic technology is achieved through the following four consistency; the parameters of the cutting knife used for the tea picking machine used for shaping and pruning and the tea picking machine used for machine harvesting are the same, the height of the cutting table with the fixed cutting knife is the same from the ground, and the fixed The cutting table of the cutting knife is consistent with the ground level, and ...

Embodiment approach 2

[0128] Others are the same as in Embodiment 1, the difference is that a straight-line cutter is used, and the crown of the tea tree after cutting is flat; here, a straight-line cutter is used to replace an arc-shaped cutter, and other leveling control strategies and cutter height control Strategies are the same as the picking method of circular arc cutter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com