Gluing visual detection method and device

A visual inspection and gluing technology, which is applied in the direction of optical testing for defects/defects, can solve problems such as safety hazards, lower battery yields, and product rejection, and achieve the effects of improving accuracy, reducing labor intensity, and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

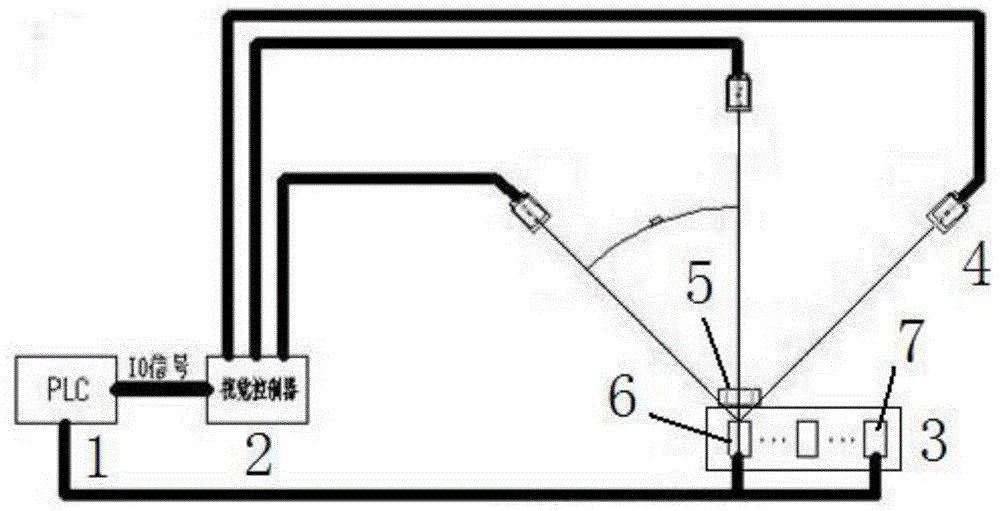

[0030] Such as figure 1In the described embodiment, a kind of gluing visual detection device comprises PLC controller 1, visual controller 2, camera 4 and battery displacement mechanism 3, and there are three cameras 4, and three cameras 4 are in the same plane, relatively The angle between two adjacent cameras 4 is 120 degrees. The PLC controller 1 is connected to the vision controller 2 and the battery displacement mechanism 3. The vision controller 2 is connected to the camera 4. The detection station 6 of the battery and the rejection station 7 of the battery after rejecting unqualified gluing, the camera 4 is placed above the detection station 6 of the battery shift mechanism 3, and the axis direction where the camera 4 shoots is the same as the location where the detection station 6 is located. The axis directions intersect each other, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com