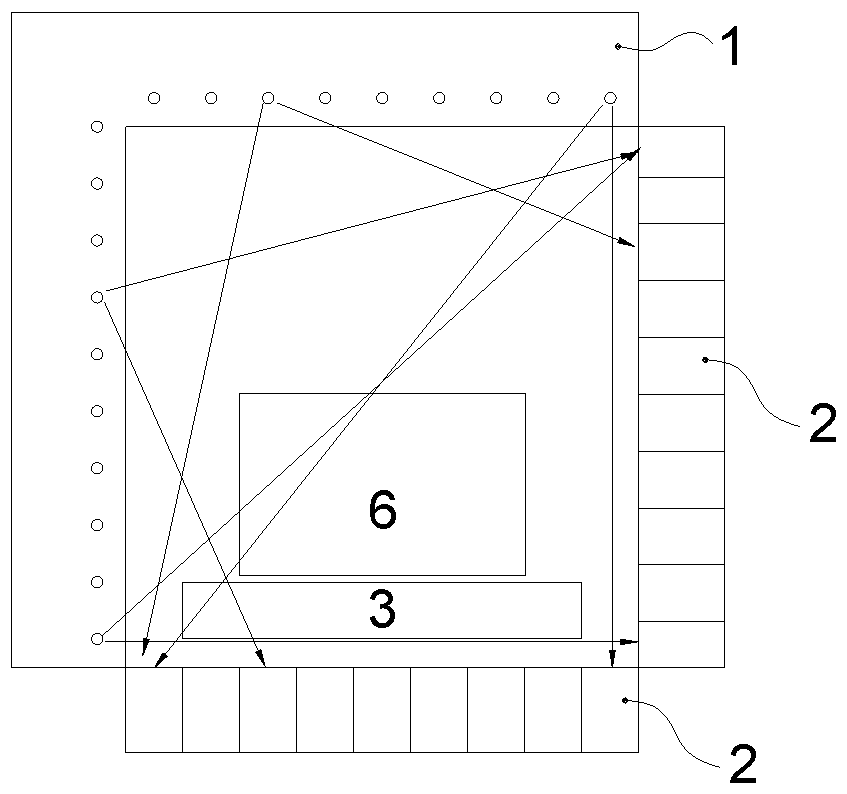

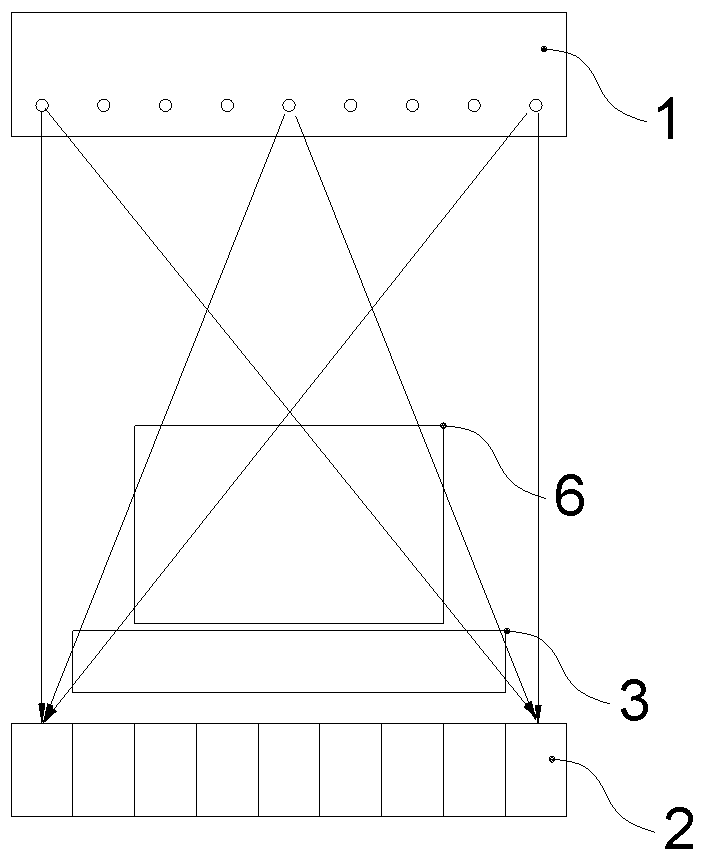

X-ray product quality automatic detection device

An automatic detection device, a technology for product quality, applied in measurement devices, material analysis using radiation, material analysis using wave/particle radiation, etc. Limited range and other problems, to achieve the effect of fast detection, no dead angle in detection, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

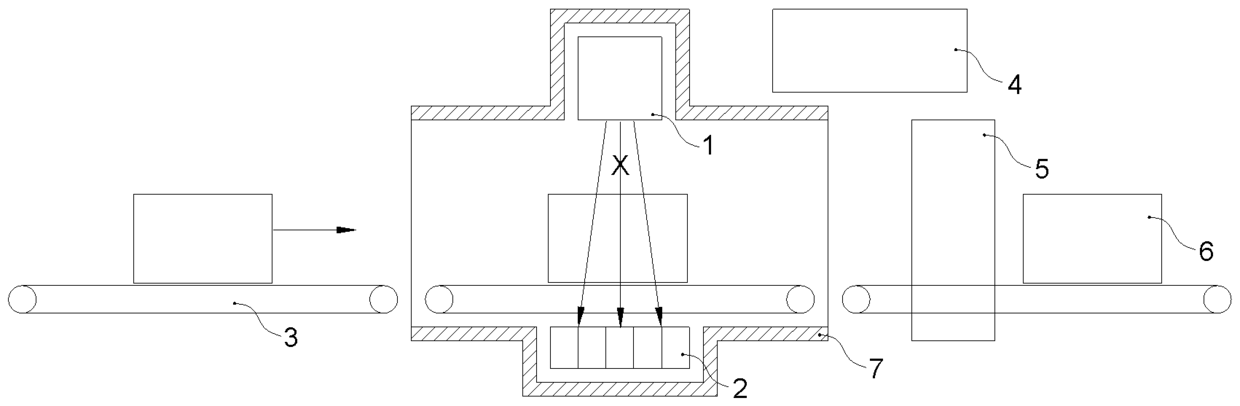

Embodiment approach 2

[0069] Embodiment 2 is an X-ray product quality on-line detection device. Except that the transmission device 3 is different from Embodiment 1, the structures and working principles of other parts are the same as Embodiment 1, that is, in this embodiment Among them, the conveying device 3 is located between the distributed X-ray source 1 and the detector 2, carries the inspected product 6 through the X-ray radiation area, and is arranged as a continuous conveying structure matching the production line of the inspected product 6 .

[0070] In Embodiment 2, the arrangement of the conveying device 3 to form a continuous conveying structure that matches the production line of the inspected product 6 means: (1) the conveying capacity of the conveying device 3 matches the conveying capacity of the production line, that is, All inspected products 6 produced per unit time on the production line can be carried by the transmission device 3 through the X-ray product quality online inspect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com