Omnidirectional profiling cutting table

An all-round, header technology, applied to headers, cutters, harvesters, etc., can solve the problems of not considering the flatness requirements of stubble cutting and difficulty in adapting to agricultural technical requirements, so as to avoid repeated operations and improve the comprehensive utilization of mechanization , to ensure the consistency of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

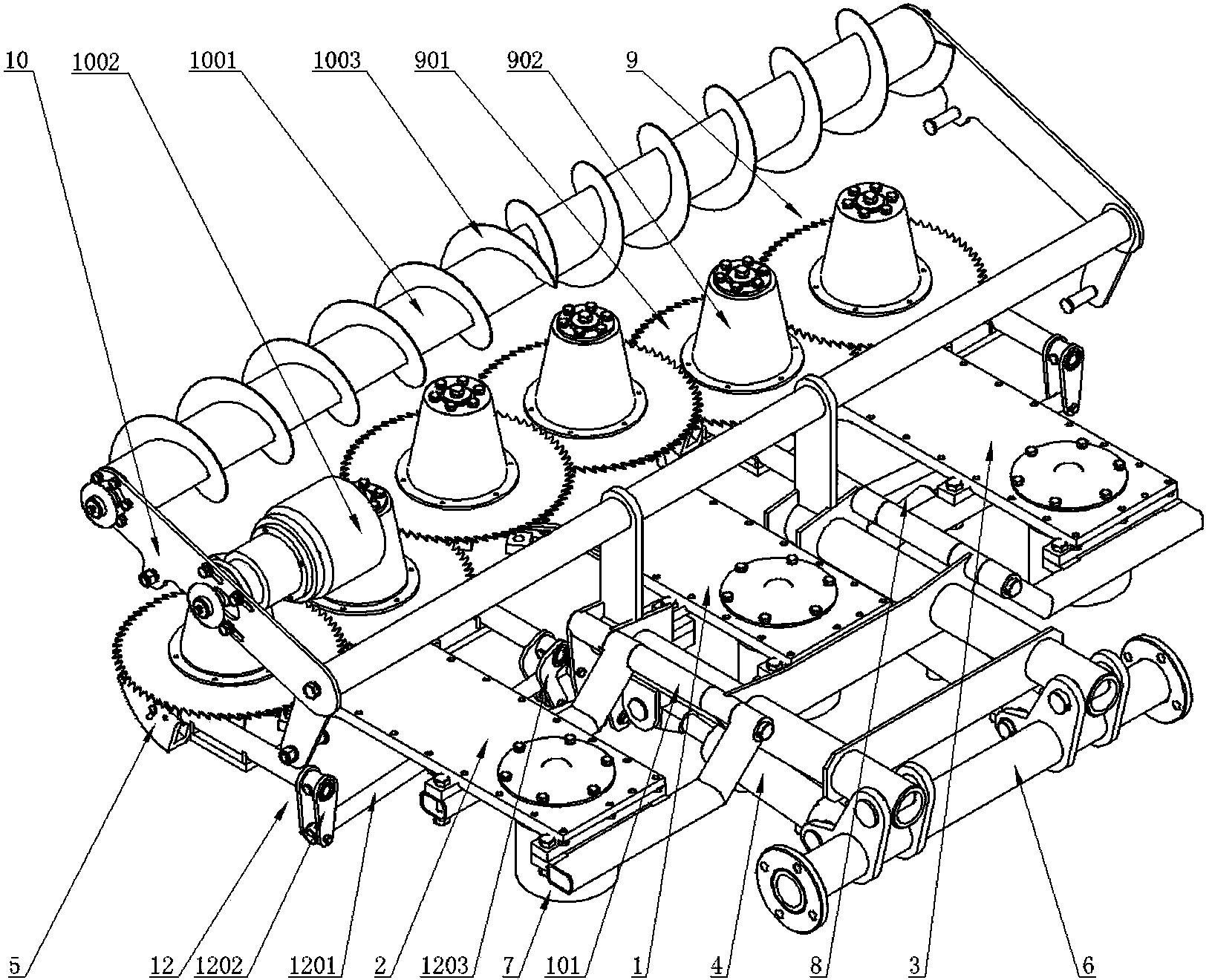

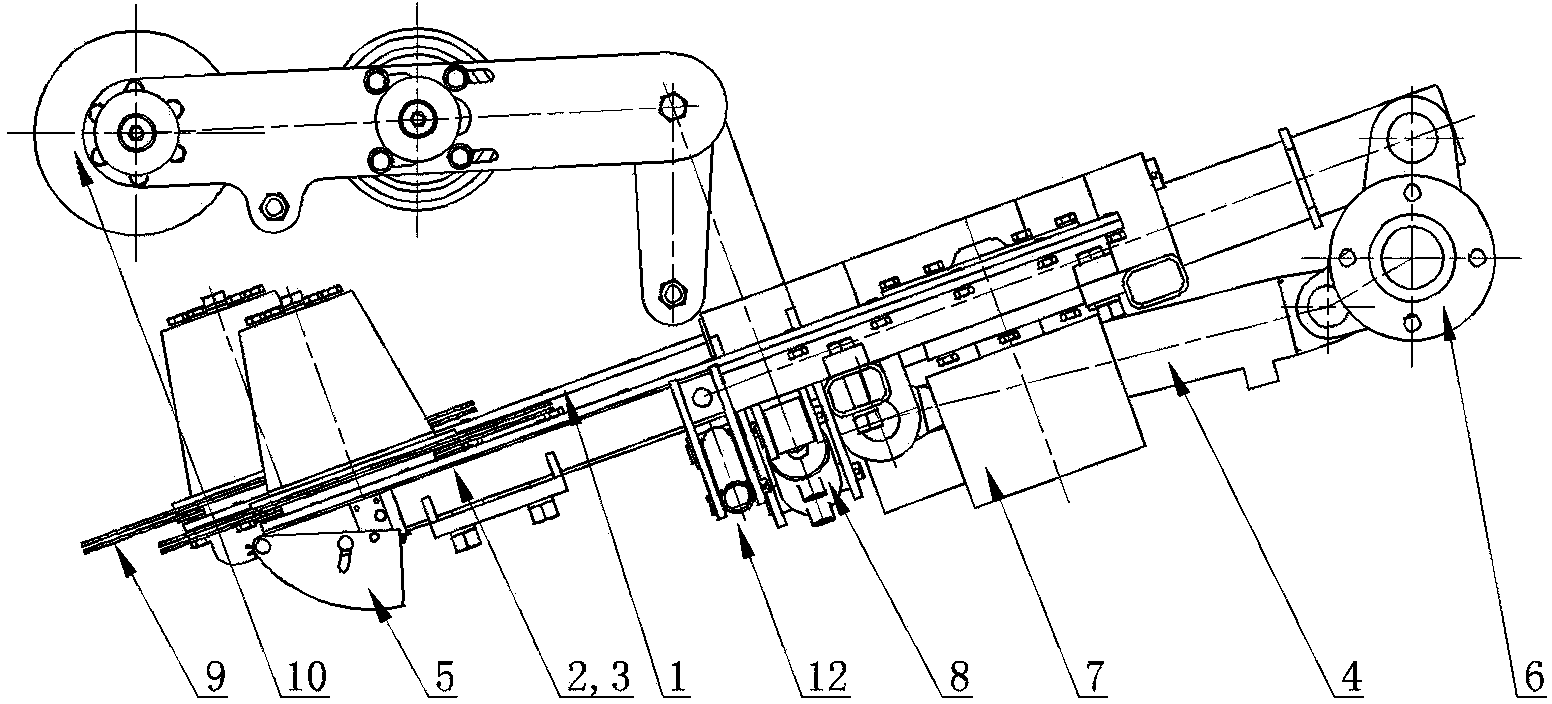

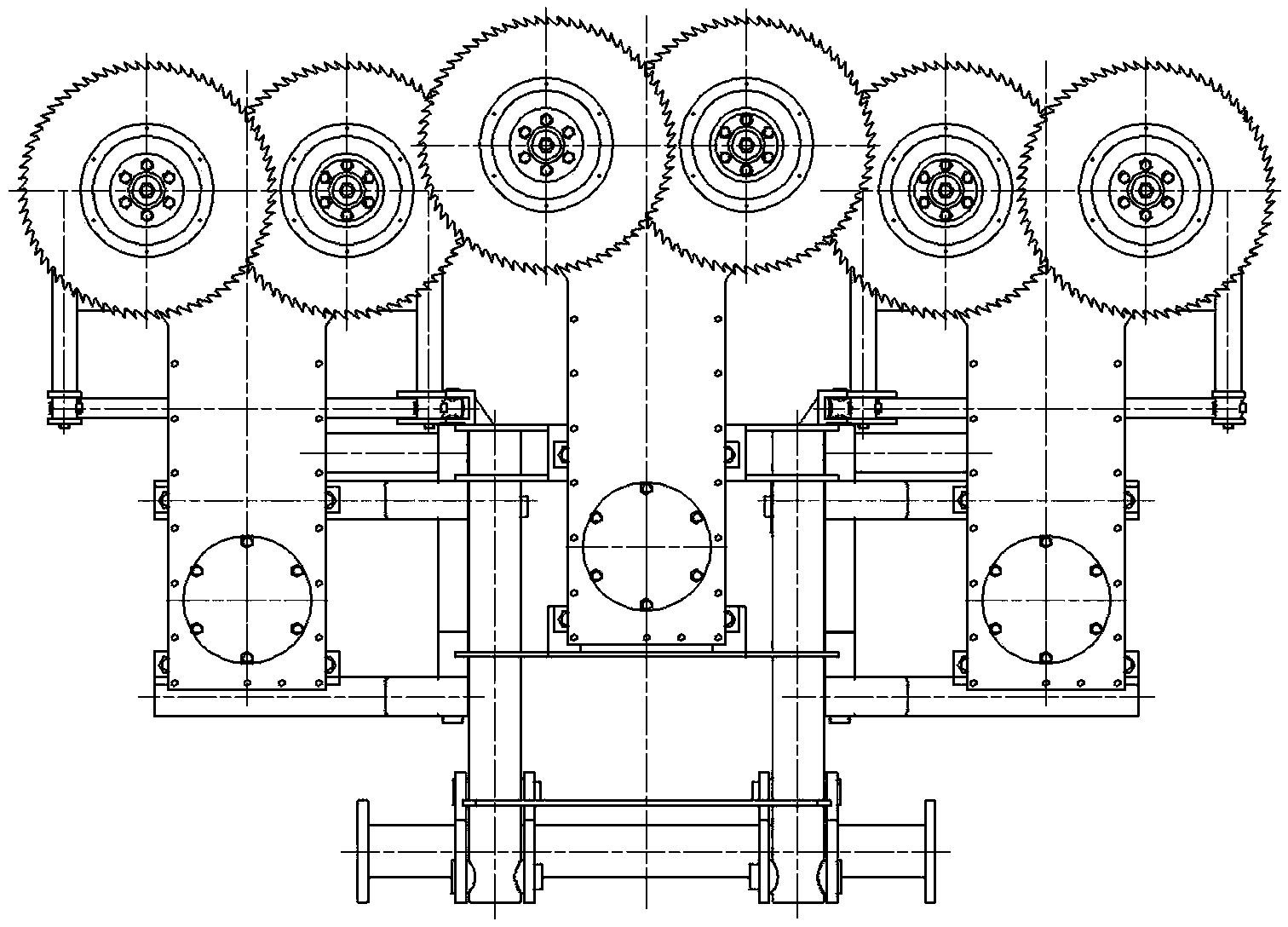

[0040] The structure of the all-round profiling header is as follows: figure 1 , figure 2 , image 3 As shown, it mainly consists of the middle profiling assembly 1, the left profiling component 2, the right profiling component 3, the longitudinal profiling cylinder 4, the profiling sensor 5, the connection frame 6, the hydraulic motor 7, the horizontal profiling cylinder 8, the circle Disc cutter 9, screw conveying device 10 and link mechanism 12 are formed.

[0041] The intermediate profiling assembly 1 is hinged with the connecting frame 6, and its relative position is controlled by the longitudinal profiling oil cylinder 4 to realize the pitching action and longitudinal profiling of the header relative to the connecting frame 6. The left profiling assembly 2 and the right profiling assembly 3 are respectively hinged with the middle profiling assembly 1 from both sides, and their relative positions are controlled by the lateral profiling oil cylinder 8 to realize the lat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com