Combine harvester gas blowing type divider suitable for coarse grain harvesting

A technology for combine harvesters and crop splitters, applied to harvesters, external crop splitters, cutters, etc., which can solve problems such as ear shedding, prevent hanging grass and entanglement of straw, and reduce the loss of headers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

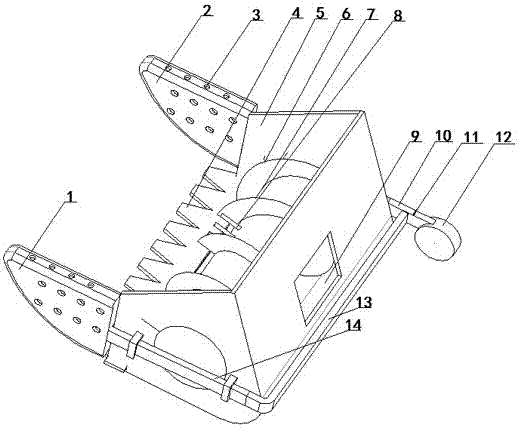

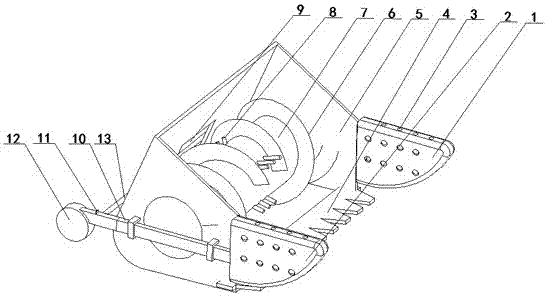

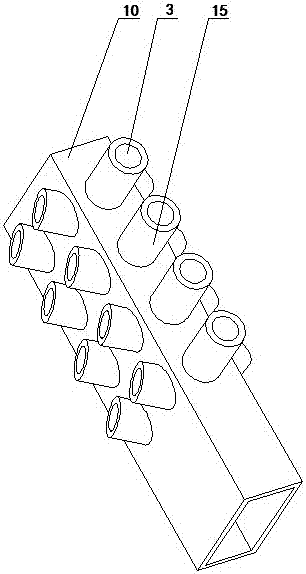

[0018] As shown in the figure, the specific implementation method is as follows:

[0019] An air-blown grain divider device for a combine harvester suitable for harvesting miscellaneous grains, comprising a header frame 5, a cutting knife 4 for harvesting miscellaneous grains is installed on the front end of the header frame 5, and a feeder is provided at the rear end of the header frame 5 Mouth 9, the frame body of header frame 5 is provided with the screw auger 7 that is used for conveying the miscellaneous grains harvested by cutter 4 to feeding port 9, and the outer circumference of screw auger 7 is provided with spirally distributed The blades 6 and some telescopic racks 8 distributed at intervals also include an air blowing and dividing grain mechanism. The air blowing dividing grain mechanism includes a blower fan 12, an air flow pipe I10, an air flow pipe II13, and an air flow pipe III14, which are used to pass through the ground to be separated. The left grain divider...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com