Patents

Literature

34results about How to "Conducive to decay" patented technology

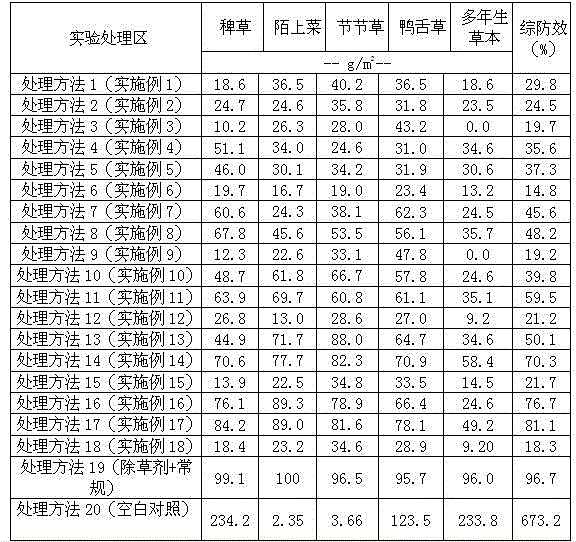

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

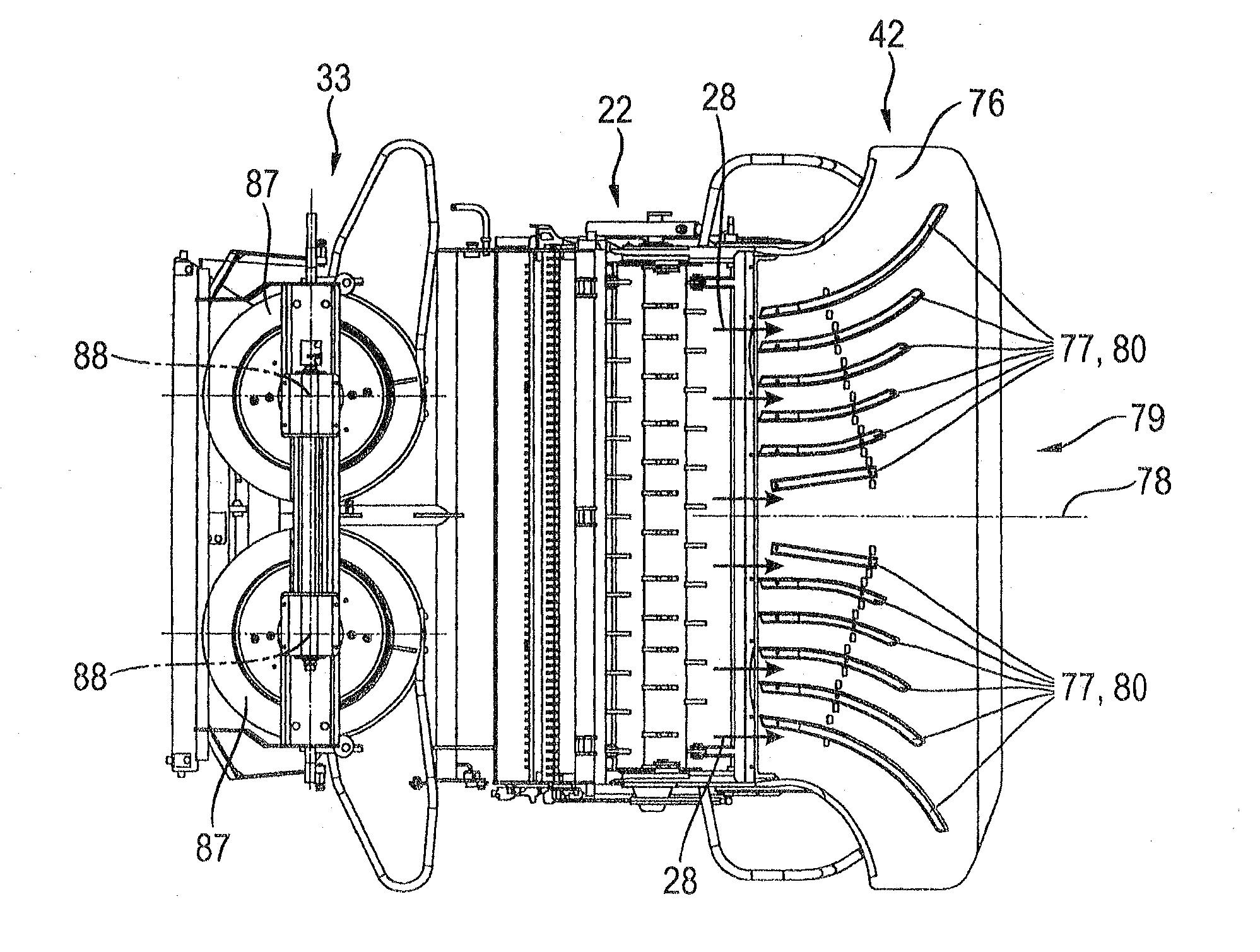

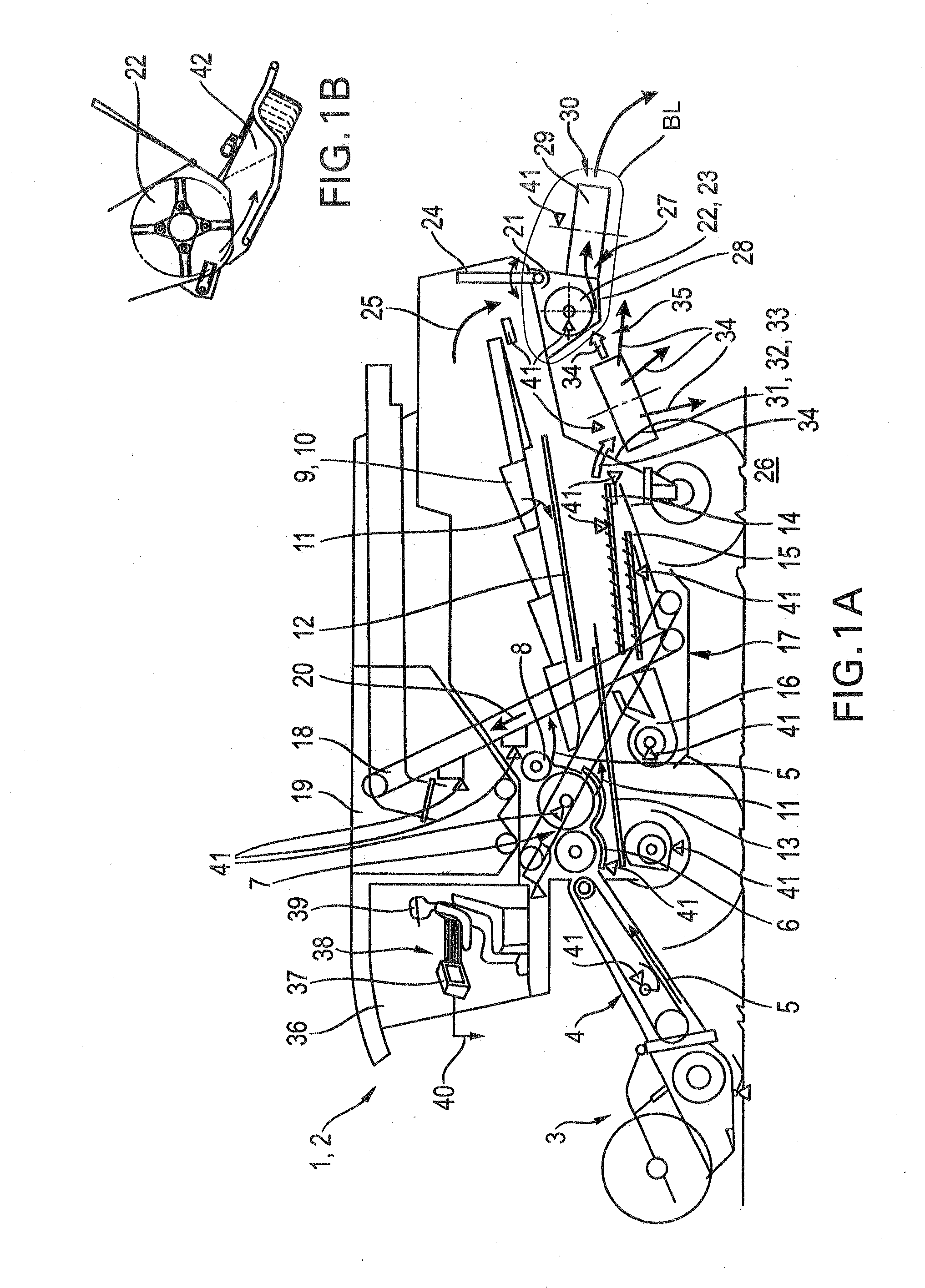

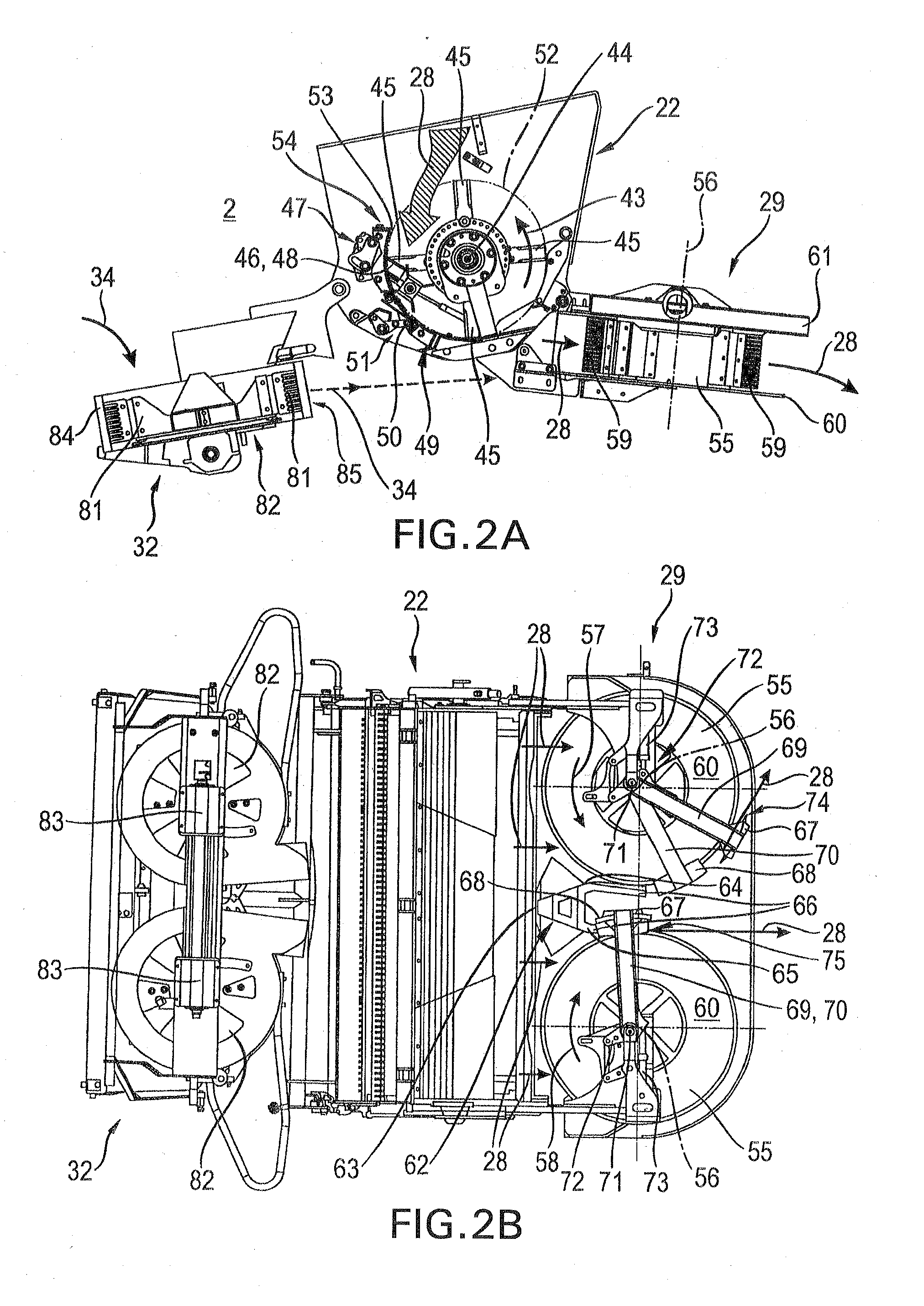

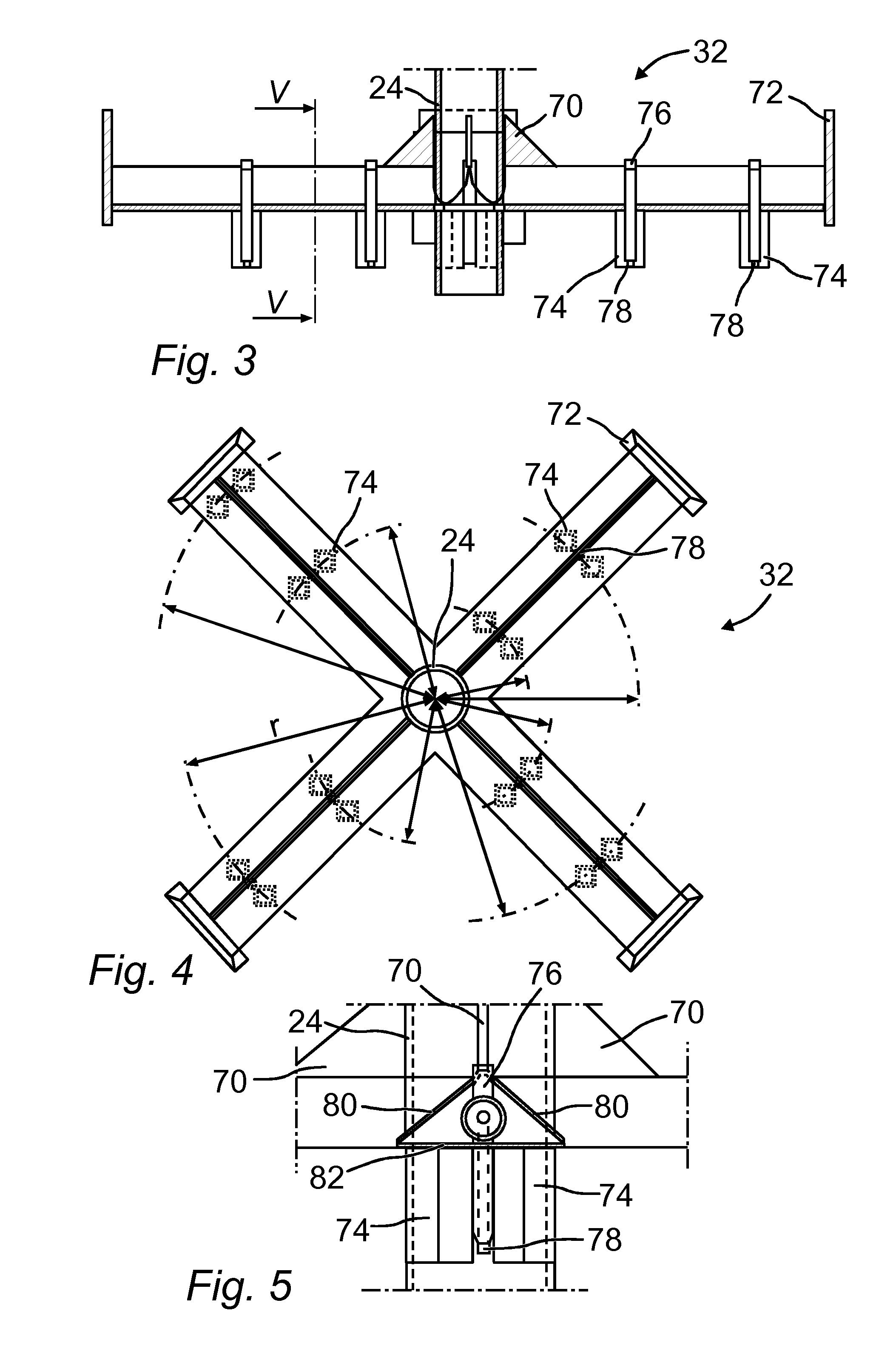

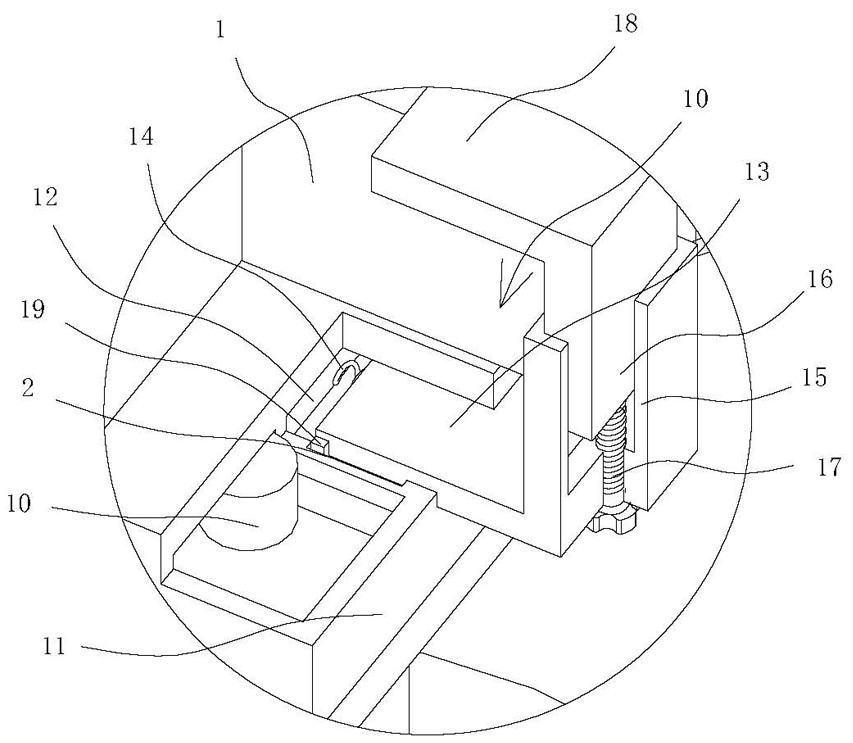

Combine harvester having a driver assistance system

ActiveUS20160088794A1Minimize energy demandConducive to decayMowersBalingCombine harvesterEmbedded system

A combine harvester includes a driver assistance system that regulates a spreading on the ground of a crop flow exiting the combine harvester. The driver assistance system includes spreading strategies that can be selected in order to regulate the spreading of the crop flow exiting the combine harvester.

Owner:CLAAS SELBSTFAHRENDE ERNTEMASCHINEN GMBH

Method for composting and returning crop straws to field

InactiveCN102417377AImprove soil nutrient contentIncrease productionBio-organic fraction processingFertilising methodsEngineeringOrganic matter

The invention provides a method for composting and returning crop straws to a field. The method comprises the following steps: digging a pit in suitable size at a corner of the field; stacking the straws in the pit in a layering way and treading down the straws; spreading a right amount of straw ageing agents and urea in each layer; after finishing stacking the straws, uniformly covering the top of the stack with the soil dug from the pit; after composting for several months, digging out the rotten straws from the pit and returning the straws to the field after harvesting crops in next season; and uniformly spreading the rotten straws in the field and using the rotten straws as base fertilizers, wherein organic matters got after the straws are rotten become clean green fertilizers. Under the condition of using the fertilizers, the hardened land becomes soft and loose, the fertilizer cost of peasants for farming is saved, and the environmental pollution problem caused by burning the straws is relieved.

Owner:FEIDONG AGRI TECH COMPREHENSIVE SERVICE CENT

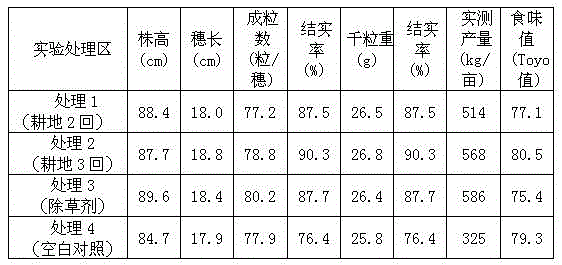

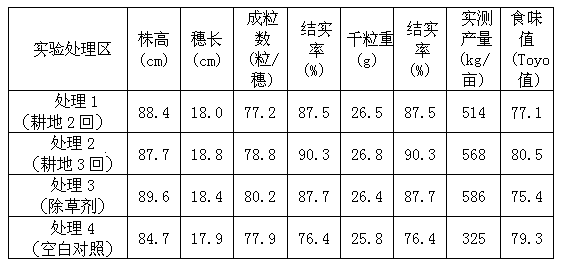

Paddy rice cultivation method

InactiveCN104521647AHigh organic contentNo pollutantsPlant protectionRice cultivationLate stageRice grain

The invention provides a paddy rice cultivation method comprising the steps of (1) shallow water field soaking, (2) plowing, (3) robust seedling transplanting, (4) water usage management, (5) rice bran spreading, (6) late-stage field management, and (7) paddy rice harvesting. With the method, problems of high weeding cost, non-thorough weeding, and high soil damage caused by the use of pesticides can be solved. Also, paddy rice yield can be improved, and the quality of rice grain produced by the paddy rice can be ensured.

Owner:CHANGSHA JINGMEI AGRI SCI & TECH

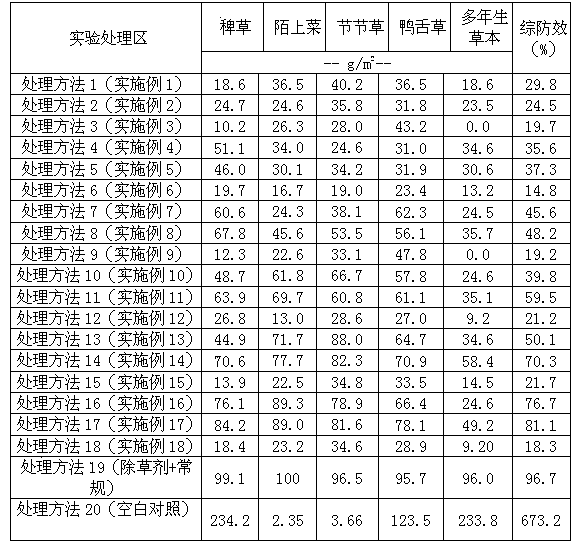

Organic rice cultivation method by utilizing farmland and rice chaff weeding

InactiveCN102715052APromote late growthRaise the ground temperatureRice cultivationWeedSite management

The invention discloses an organic rice cultivation method by utilizing farmland and rice chaff weeding, belonging to the technical field of rice production. The method comprises the steps of: soaking in shallow water; ploughing for two times or three times; transplanting strong seedlings; broadcasting rice chaff; conducting later field management and other steps. In the method, drainage is required at first and then ploughing is carried out each time, which aims at carrying away sheathed monochoria herb without spouting and floating on the surface of a water level and seeds of chufa through drainage; the rice chaff fertilization faster improve the field temperature so as to create a good sprouting environment for weed seeds, and also can reduce the oxygen content under the surface layer, thus preventing the normal growth of the weed roots and achieving purpose of killing weeds, further increasing the content of organic matters, being beneficial to improvement of rice quality. The organic rice cultivation method can be popularized and applied in rice cultivation regions.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

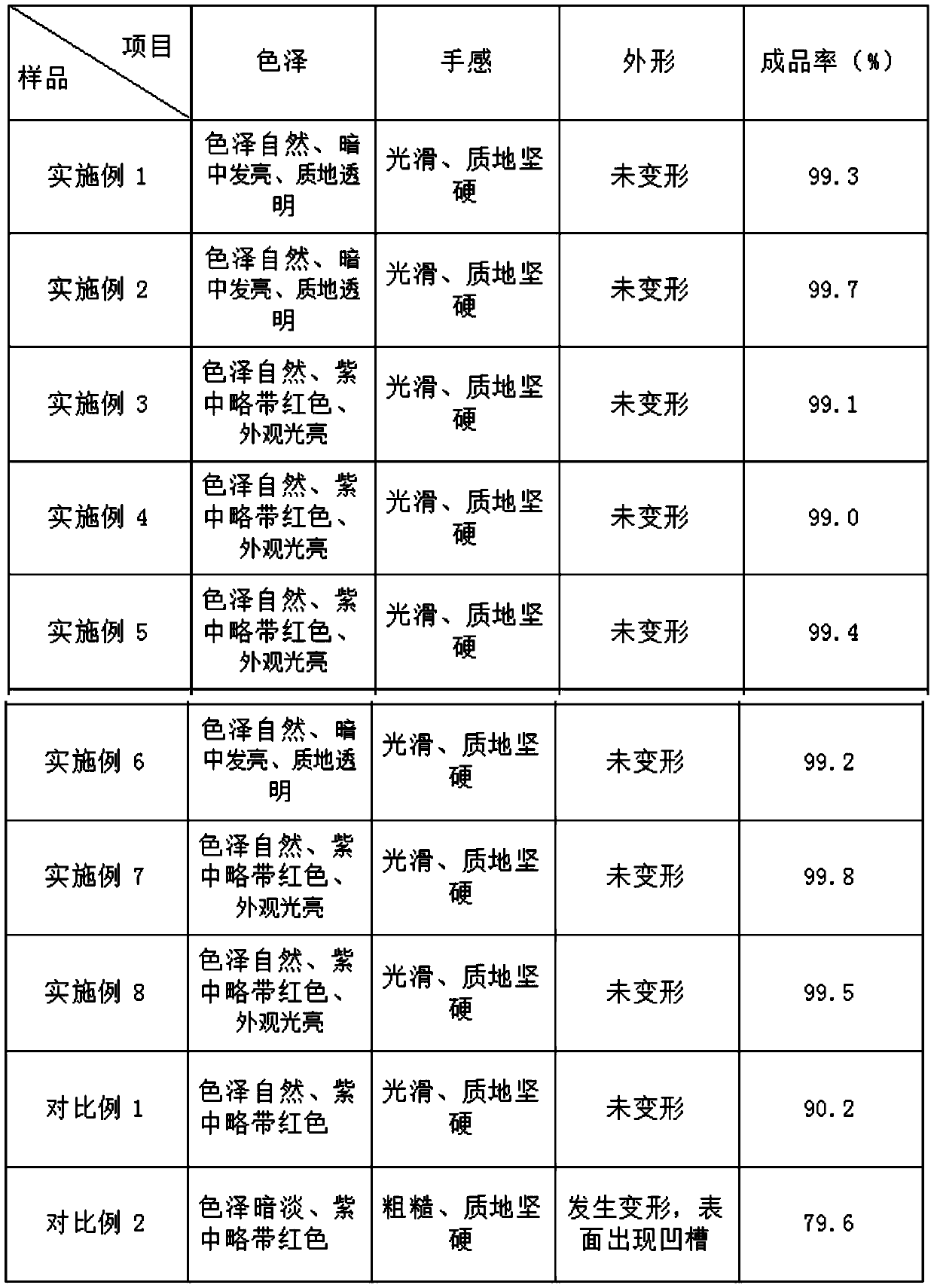

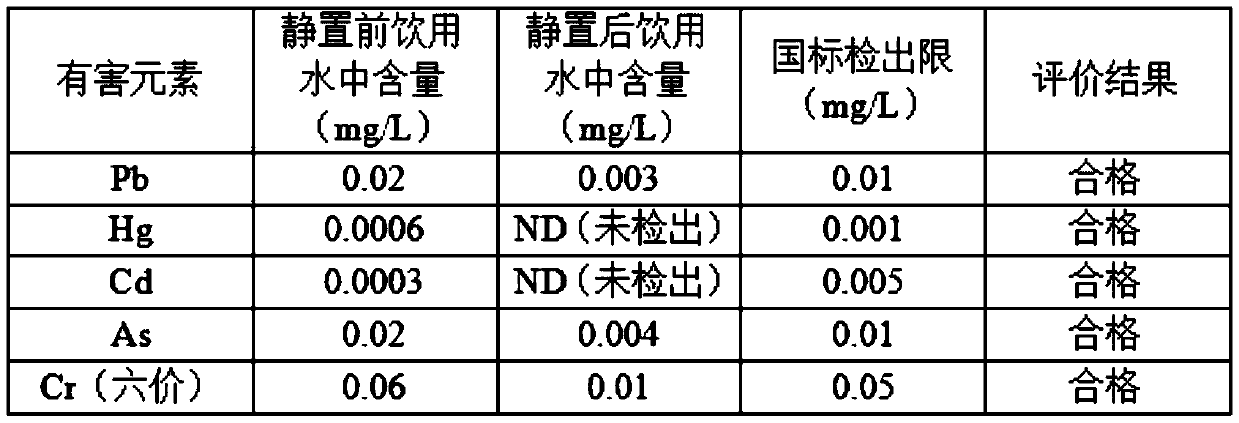

Selenium-enriched dark-red enameled pottery pug and preparation method thereof

InactiveCN111410511AGood health effectEnhance immune functionClaywaresPhysical chemistryDistilled water

The invention discloses a selenium-rich dark-red enameled pottery pug and a preparation method thereof. The dark-red enameled pottery pug comprises the following raw materials: dark-red enameled pottery pug, selenium powder, a selenium powder stabilizer, medical stone powder, tourmaline powder and mineral substance powder. The preparation method of the dark-red enameled pottery pug comprises the following steps: selecting a dark-red enameled pottery pug raw material; weathering the dark-red enameled pottery pug raw material; removing heavy metals; uniformly mixing the rest raw materials; uniformly mixing the dark-red enameled pottery pug raw material dry powder and the mixed powder, and soaking to obtain mixed pug; fishing out the mixed pug, and absorbing water; aging, hammering and pressing the mixed mud into mud blocks or mud strips for preparing the dark-red enameled pottery. The dark-red enameled pottery fired by the dark-red enameled pottery pug is high in yield, smooth in hand feeling, not easy to deform and natural in color; the distilled water brewed by the dark-red enameled pottery can dissolve out various trace elements, especially selenium elements, necessary for human bodies; the standing drinking water for the dark-red enameled pottery has the effect of remarkably reducing the content of toxic heavy metals.

Owner:JIANGSU BICHENG PURPLE SANDS TECH CO LTD

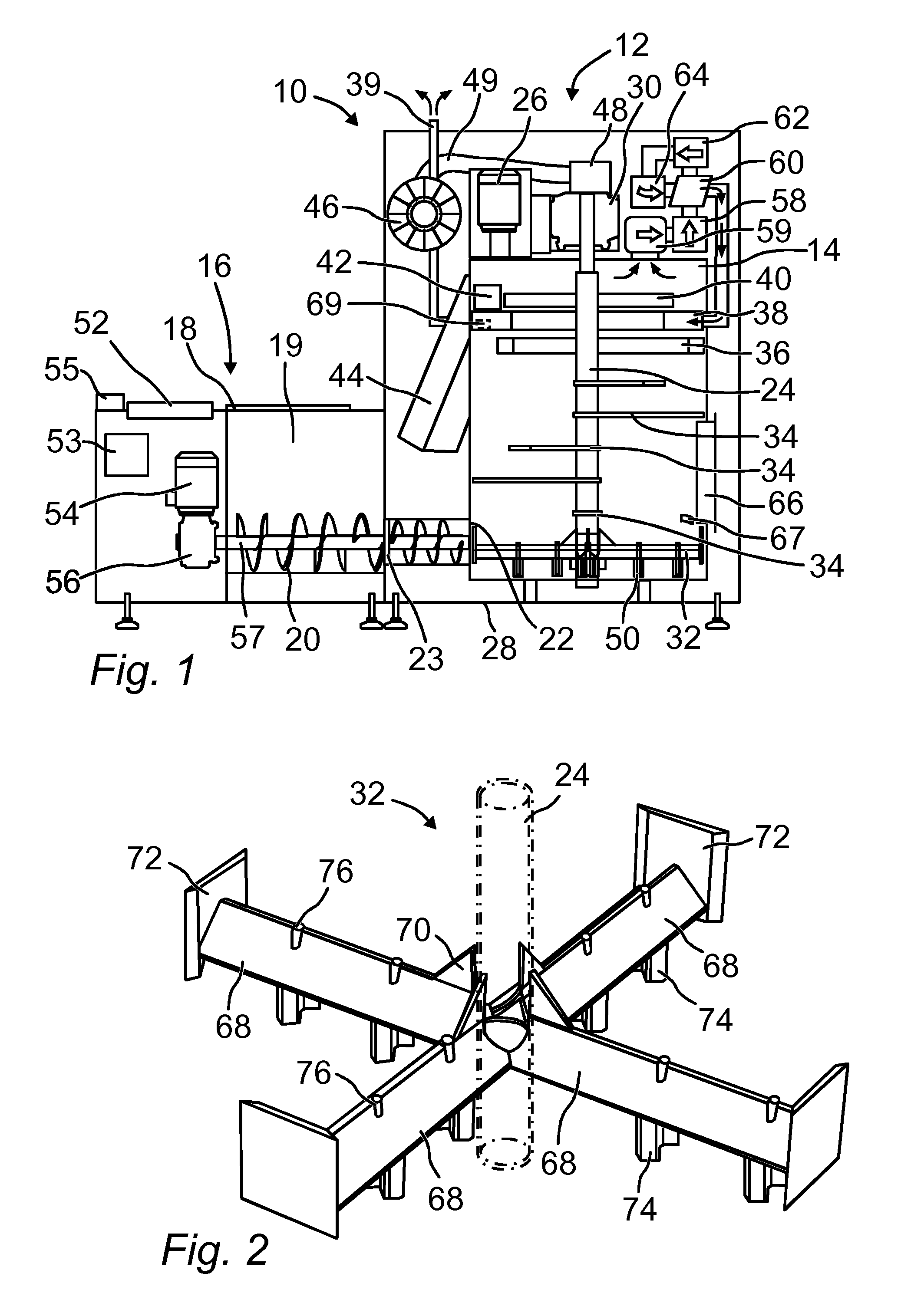

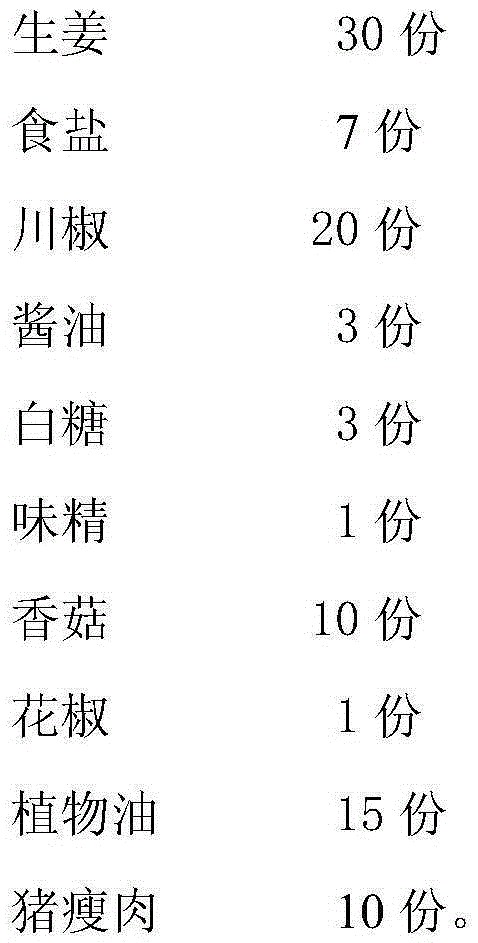

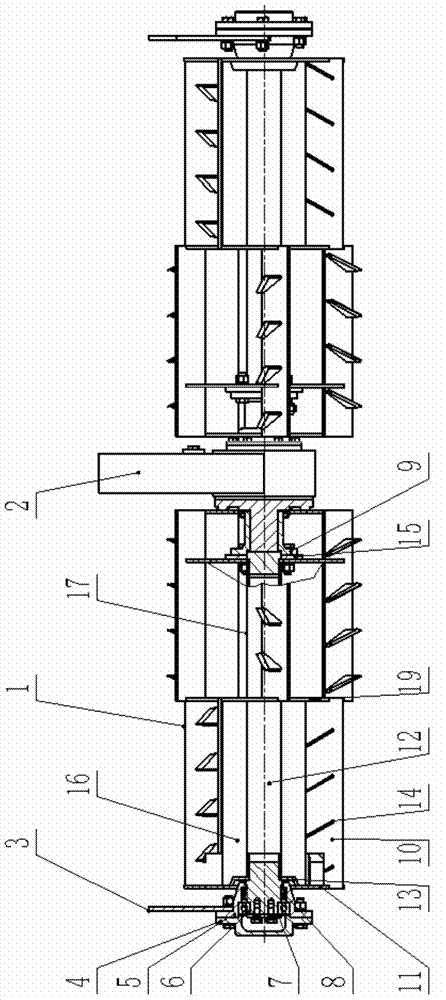

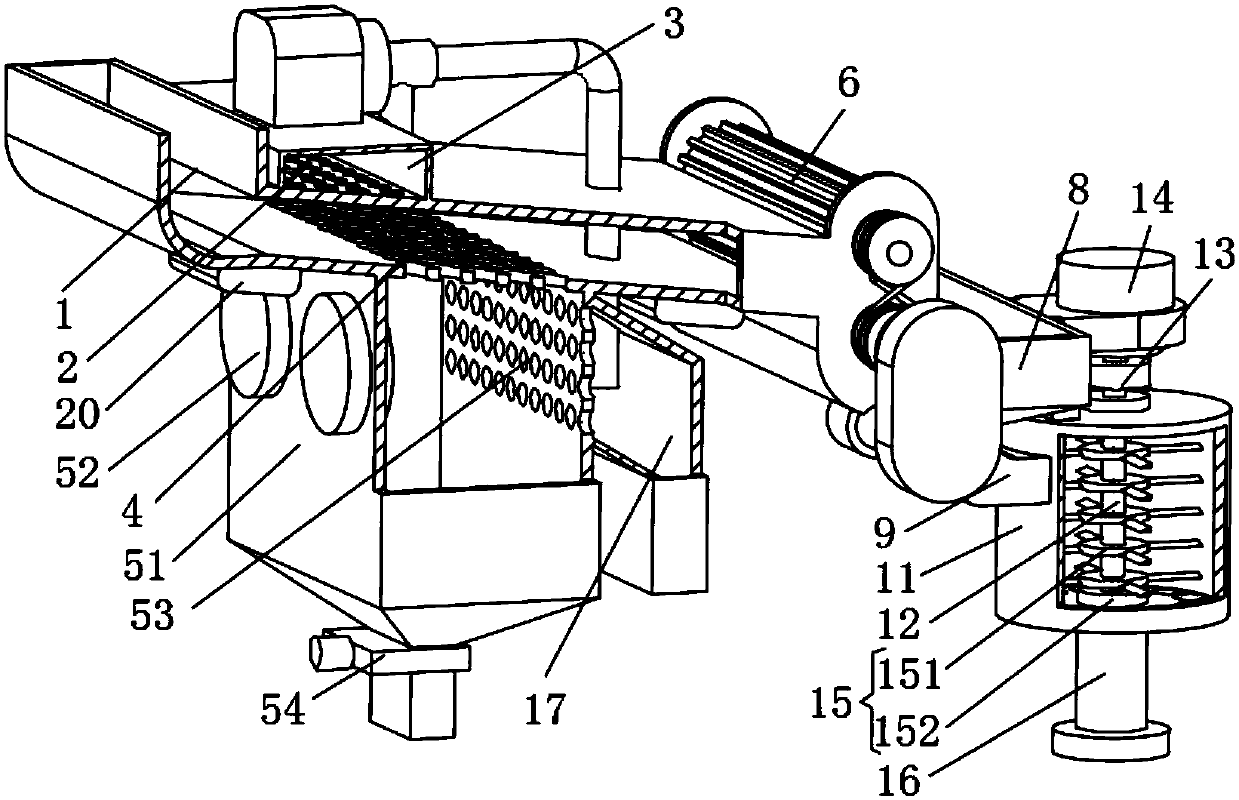

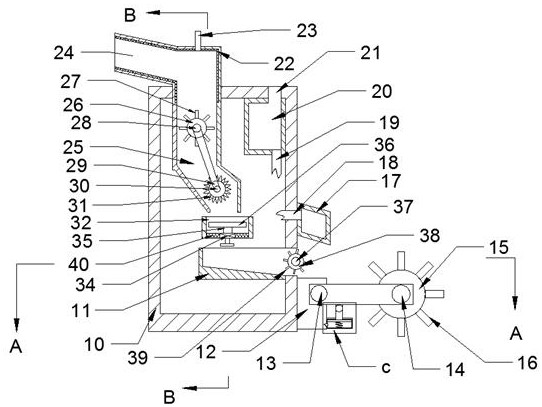

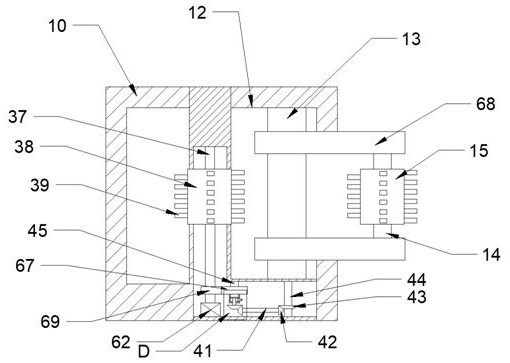

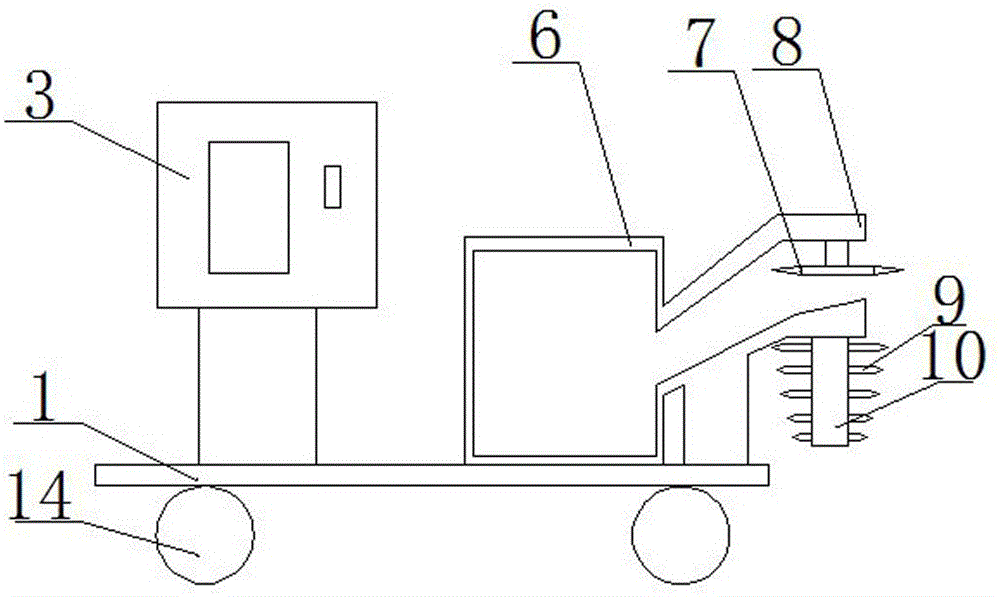

An organic waste composter and a method of composting organic waste material

InactiveUS20160122255A1Improve efficiencyEasy to operateBioreactor/fermenter combinationsBio-organic fraction processingCompostWaste material

An organic waste composter (10) comprising a processing vessel (14) having at least one heating unit, a stirring mechanism, a means (46) for injection of air for composting waste, a waste inlet hatch (18), a waste input receptacle (19), a rotating auger (20) arranged to receive waste from said waste input receptacle (19), to cut said waste and to transport said waste to a first end of said processing vessel, and a heating unit (38) located proximal to a second end of said vessel (14). Said rotating auger (20) is operatively connected to a control unit (53) arranged to activate said rotating auger (20) periodically during a rotation period extending at least 15 seconds and being shorter than 10 minutes every 60 minutes. A method of composting organic waste comprising a) receiving waste material, b) inputting waste material into a first end section of a vessel (14) by rotating said auger (20), c) stirring the waste material in said vessel (14), d) heating the composted material at a second end section of said vessel (14), e) outputting composted material from said vessel (14), and f) rotating said auger (20) periodically during a rotation period extending at least 15 seconds and being shorter than 10 minutes every 60 minutes.

Owner:GRACE ORGANIC

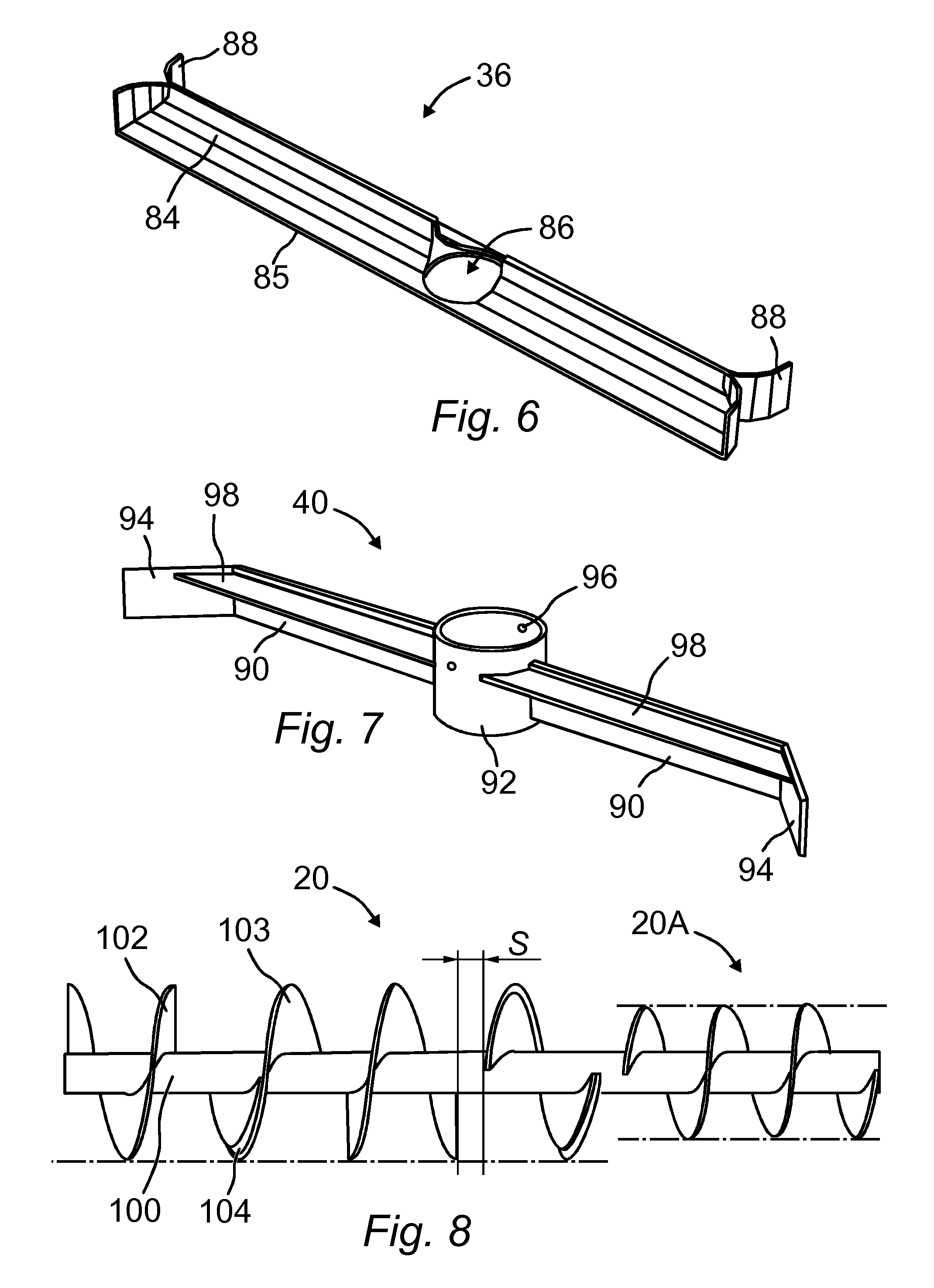

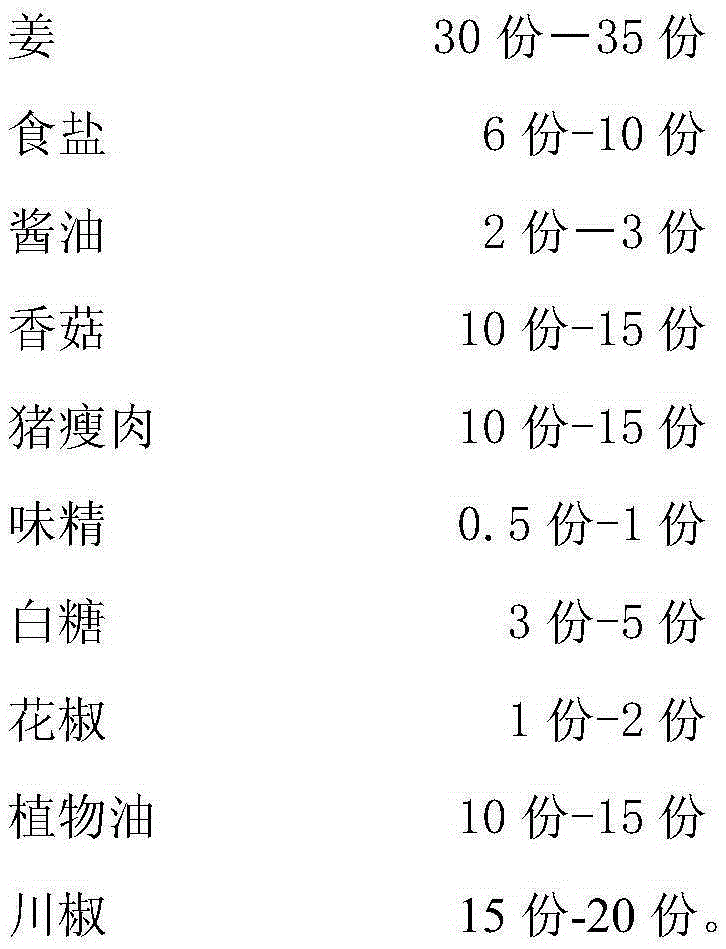

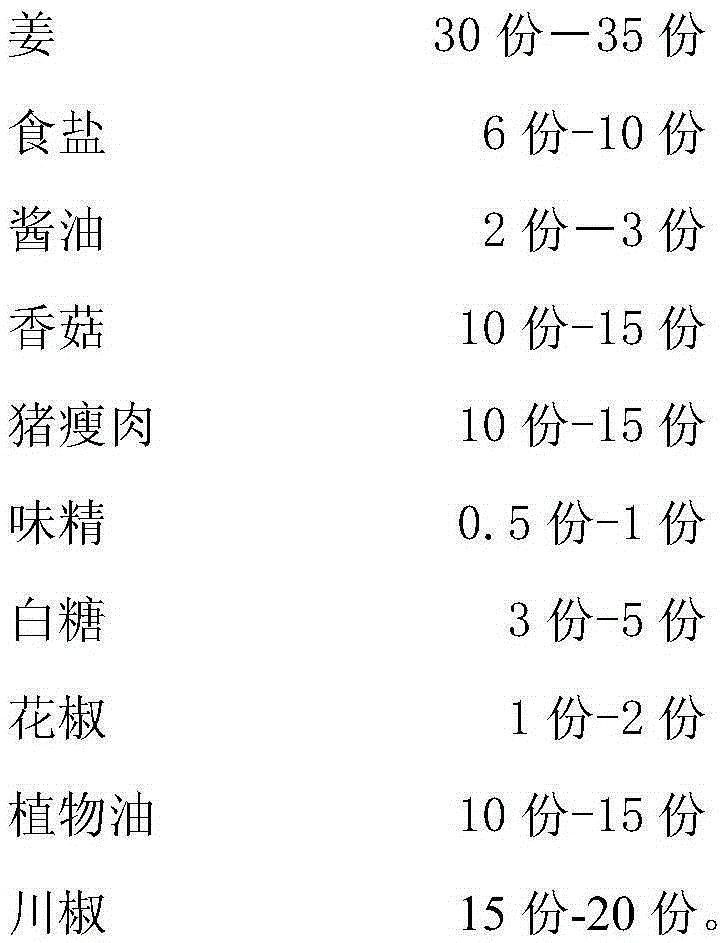

Ready-to-eat ginger appetizer and preparation method thereof

InactiveCN105310033AMarinated evenlyImprove palatabilityClimate change adaptationFood ingredient functionsMonosodium glutamateReady to eat

The invention discloses a ready-to-eat ginger appetizer and a preparation method thereof. The preparation method comprises the following steps: pickling ginger, dicing the pickled ginger, putting the diced ginger into an ultrasonic cleaner for ultrasonic treatment, and then removing water; drying the diced ginger without water in a drying box, and then cooling the dried diced ginger; carrying out primary roasting, and then cooling the roasted diced ginger; carrying out secondary roasting for 2-4 hours, and then taking out the finally obtained diced ginger for standby application; dicing shiitake, and frying the diced shiitake in hot vegetable oil till the fried diced shiitake becomes golden yellow; cleaning pork tenderloin, and dicing the cleaned pork tenderloin; cleaning Szechwan peppers, and dicing the cleaned Szechwan peppers; putting vegetable oil in a wok for heating, putting zanthoxylum in the hot vegetable oil for frying till the zanthoxylum aroma appears, taking out the fried zanthoxylum, and leaving the hot vegetable oil for standby application; mixing the following ingredients in parts by weight: 30-35 parts of the finally obtained diced ginger, 10-15 parts of the fried diced shiitake, 10-15 parts of the diced pork tenderloin, 1-2 parts of zanthoxylum, 15-20 parts of the diced Szechwan peppers, 2-3 parts of soy, 0.5-1 part of monosodium glutamate, 3-5 parts of white sugar and 6-10 parts of table salt; pouring 10-15 parts of the standby hot vegetable oil for uniform mixing and bottling, and then carrying out sterilization and cooling, so as to obtain the ready-to-eat ginger appetizer. No any artificially synthesized preservative and essence are added in the preparation process, so that the ready-to-eat ginger appetizer has a good taste, and the problem of a difficulty in ginger storage is solved.

Owner:BOHAI UNIV

Grape planting method

InactiveCN106386373AConducive to decayReduce planting costsBioloigcal waste fertilisersCultivating equipmentsVitis viniferaShoot

The invention provides a grape planting method, and relates to the field of agricultural planting. The grape planting method comprises the following steps: preparing cutting shoots of grapes, constructing a seedbed, planting the cutting shoots, accelerating germination of the grapes, performing topdressing management, performing shaping and trimming, and harvesting the grapes. According to the grape planting method, when the seedbed is constructed, distillers' grains generated in long-term grape wine production, and grape twigs left in the preparing process of grape cutting shoots are stirred and mixed, the grape twigs can be treated by zymophyte in the distillers' grains when being stirred and mixed, the stirred twigs can be rotted and converted into a base fertilizer, and meanwhile plants and weeds generated in the process of soil preparation can be poured into furrows to be adhered to the surface of the base fertilizer, so that a fertilizer needed by the grapes to grow can be formed, the amounts of chemical fertilizers which are additionally applied in later topdressing management can be reduced, the planting cost can be reduced for fruit farmers, the operation amount of agricultural operators can be reduced, and the economic benefits of the fruit farmers can be increased.

Owner:株洲果美生态农业有限公司

Polyolefin dispersion compositions for making high vapor transport hydrophobic coatings

The present invention provides compositions for water vapor permeable hydrophobic coating comprising a blend of (i) a primary polyolefin dispersion of one or more large particle size polyolefins having a melting point of at least 95° C., and an average particle size of from 1 to 5 microns, and containing a volatile base and a 14 to 40 carbon long chain linear carboxylic acid dispersing agent, and (ii) a film forming second dispersion of one or more polymers having an average particle size of from 0.1 to 1.0 microns chosen from one or more polyolefins having a melting point from 50 to 90 ° C. further containing an at least partially neutralized olefin containing dispersing agent, one or more alkyl celluloses which further contain a plasticizer having a boiling point of 250° C. or greater and containing an at least partially neutralized olefin containing dispersing agent, and one or more acrylic emulsion polymers having a Tg of from 0 to 60° C. wherein the particle size ratio of the primary polyolefin dispersion to the second dispersion ranges from 3:1 to 29:1.

Owner:DOW GLOBAL TECH LLC

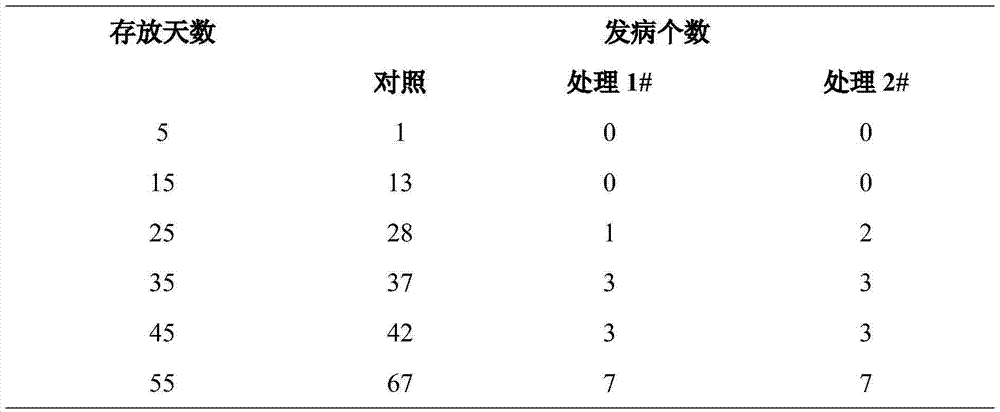

Method for storing and fresh keeping of ginkgo biloba

ActiveCN105230779ALow toxicityNot easy to absorbSeed preservation by freezing/coolingChemistryRelative humidity

The invention discloses a method for storing and fresh keeping of ginkgo biloba. The method comprises the following steps: (1) sorting ginkgo biloba in an optimum gathering period, peeling the sorted ginkgo biloba, cleaning and disinfecting the peeled ginkgo biloba with a polyhexamethylene guanidine hydrochloride solution, drying the cleaned and disinfected ginkgo biloba at a room temperature by airing, and removing ginkgo biloba with mechanical damages, empty ginkgo biloba, wormy ginkgo biloba and decomposed ginkgo biloba; (2) placing the ginkgo biloba processed in the step (1) in the condition of controlling the humidity with dry fog, controlling the relative humidity to be 93-98%, controlling the moisture content atomized granules to be 2-10 mum without falling water wetting / dew condensation phenomena, and storing the ginkgo biloba at the temperature of 0-4 DEG C. According to the method disclosed by the invention, the phenomena of mildew and rot and calcification caused by dehydration in the storage process of the ginkgo biloba can be effectively avoided. The method disclosed by the invention is used for storing the ginkgo biloba, after being stored for 360 days, the mildew and rot rate of the ginkgo biloba is below 5%, the ginkgo biloba does not dehydrate, the glutinous performance of the ginkgo biloba does not fall, and the quality of the ginkgo biloba is maintained better.

Owner:SUZHOU FULL FORTUNE FOOD CO LTD +1

Organic rice cultivation method by utilizing farmland and rice chaff weeding

The invention discloses an organic rice cultivation method by utilizing farmland and rice chaff weeding, belonging to the technical field of rice production. The method comprises the steps of: soaking in shallow water; ploughing for two times or three times; transplanting strong seedlings; broadcasting rice chaff; conducting later field management and other steps. In the method, drainage is required at first and then ploughing is carried out each time, which aims at carrying away sheathed monochoria herb without spouting and floating on the surface of a water level and seeds of chufa through drainage; the rice chaff fertilization faster improve the field temperature so as to create a good sprouting environment for weed seeds, and also can reduce the oxygen content under the surface layer, thus preventing the normal growth of the weed roots and achieving purpose of killing weeds, further increasing the content of organic matters, being beneficial to improvement of rice quality. The organic rice cultivation method can be popularized and applied in rice cultivation regions.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

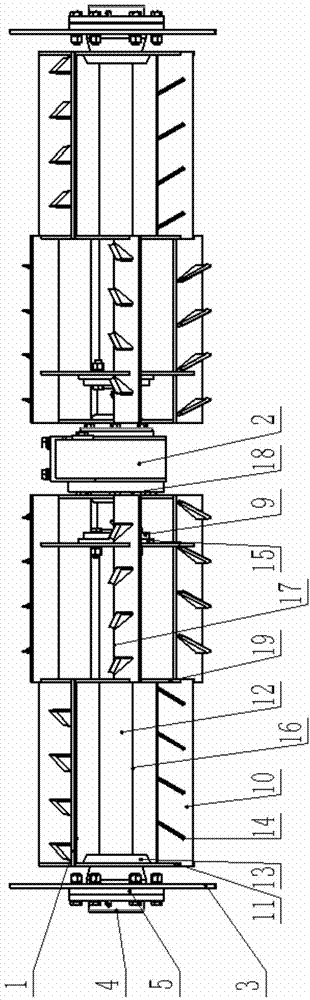

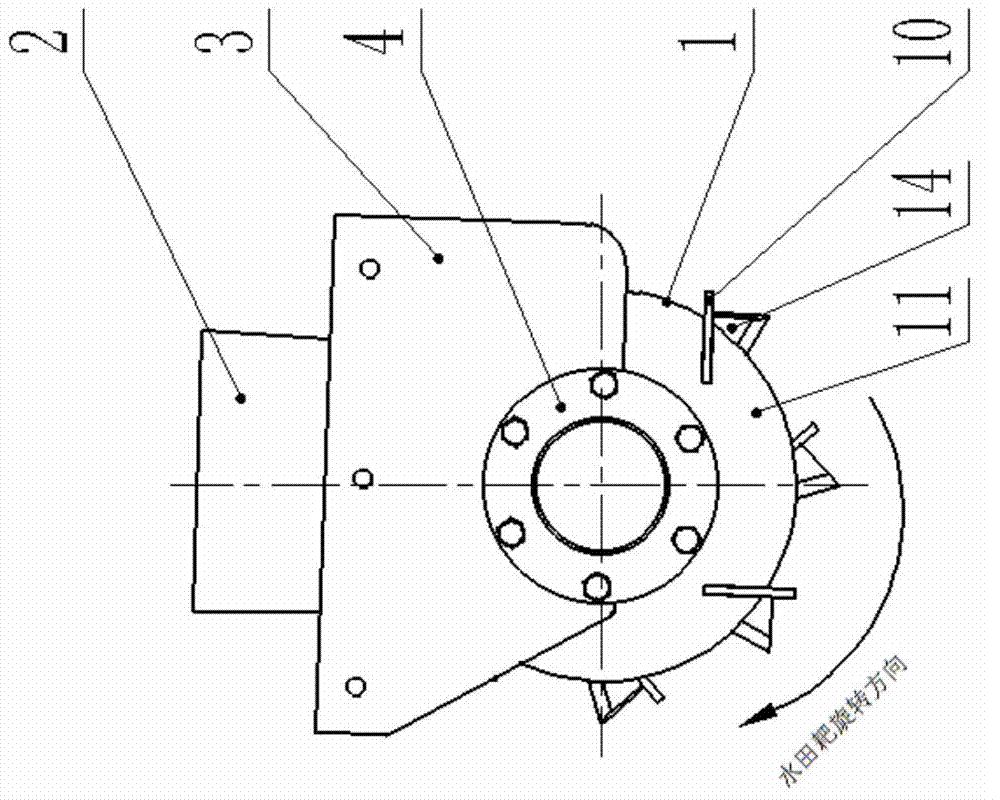

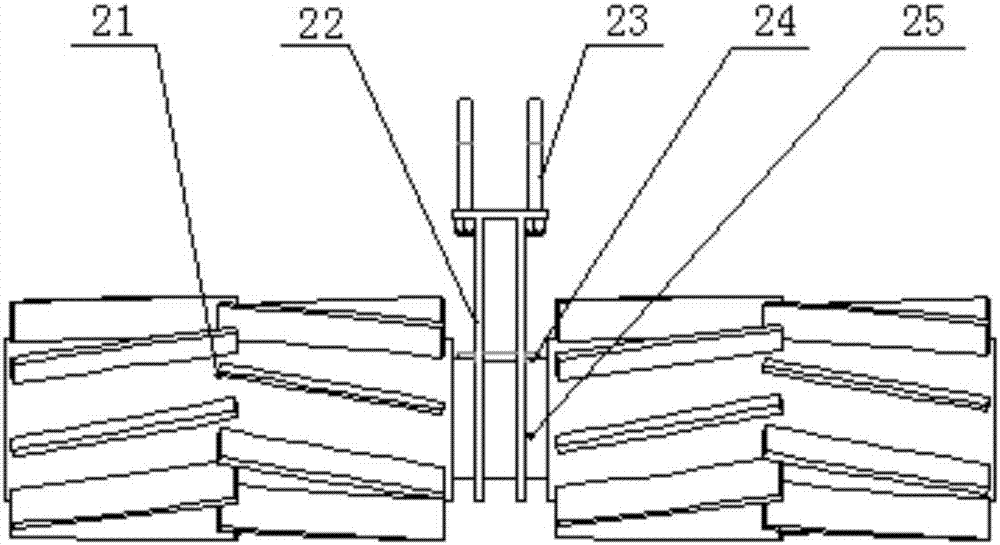

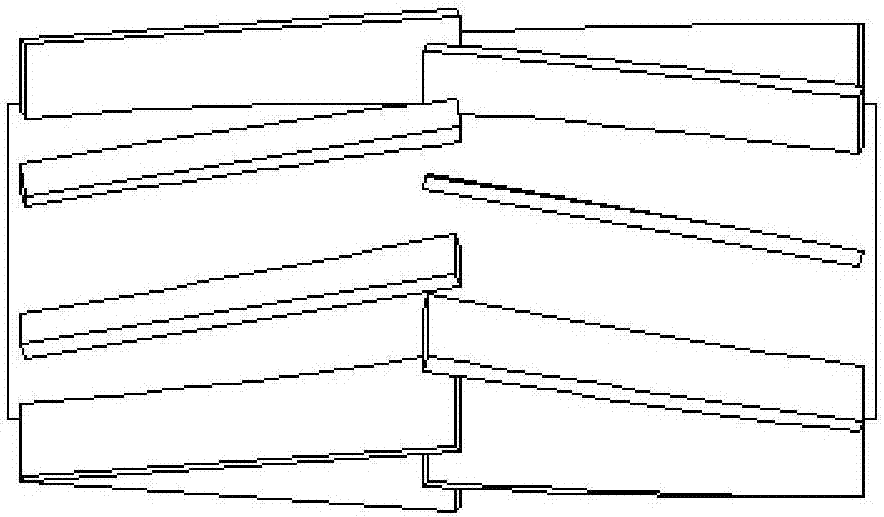

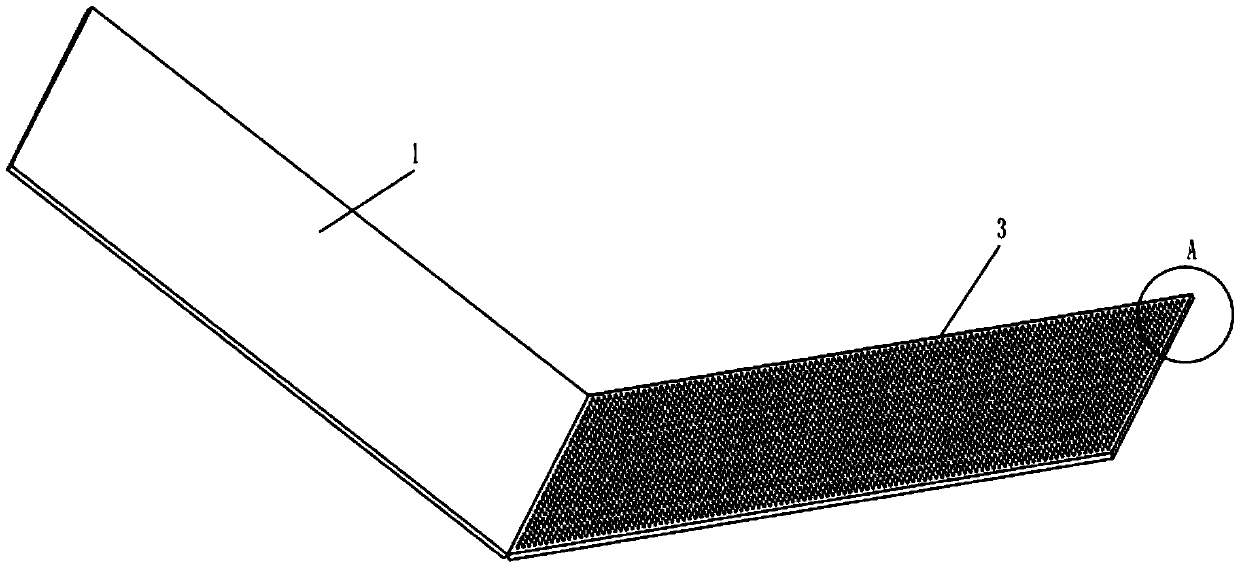

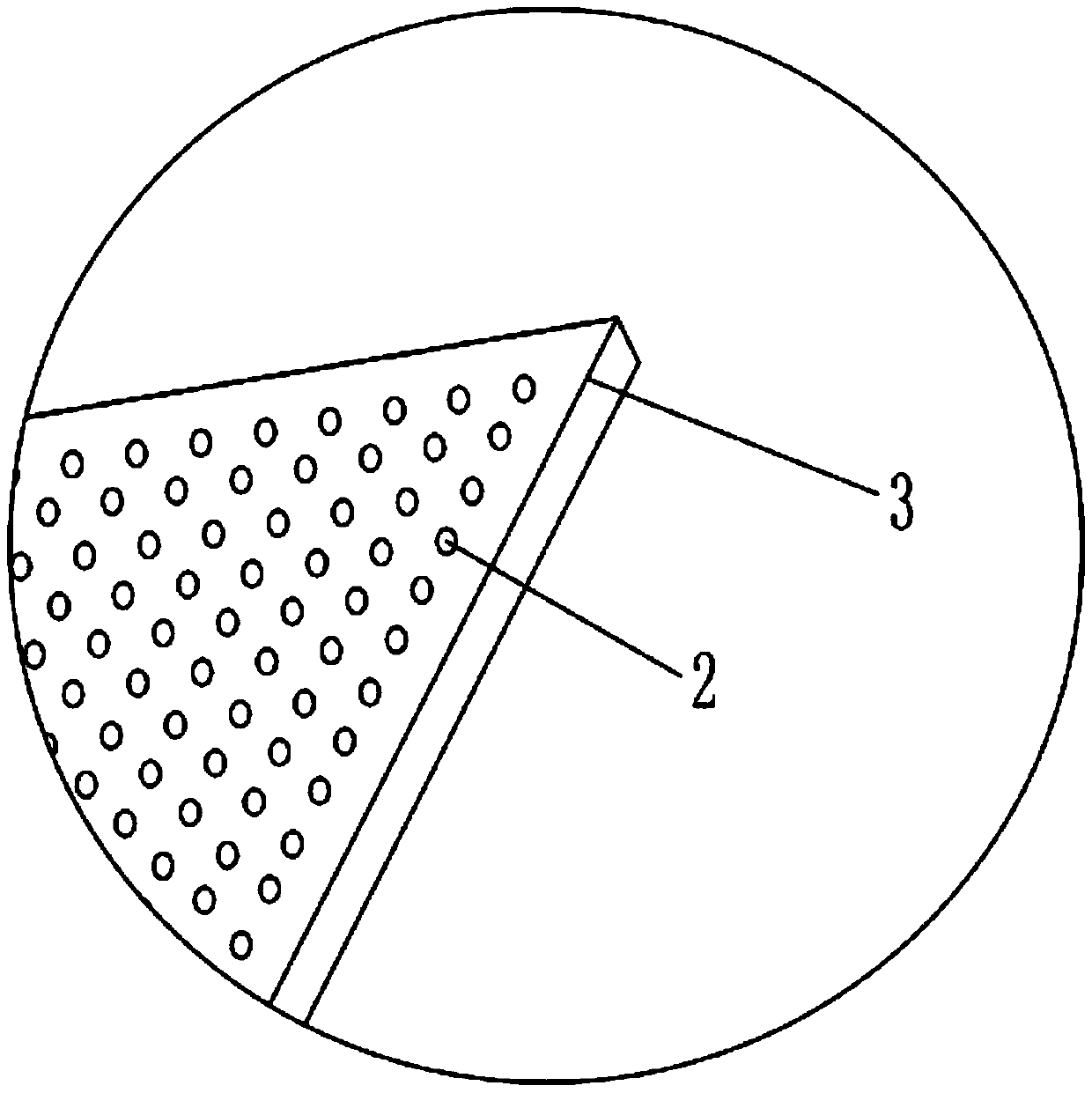

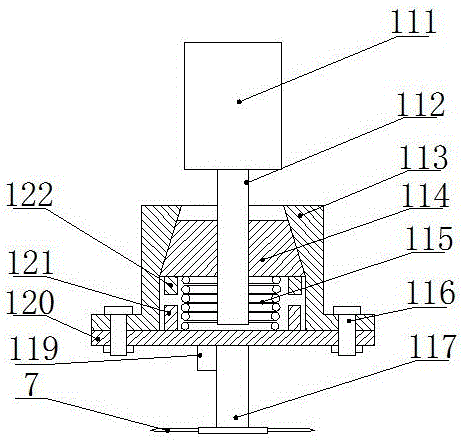

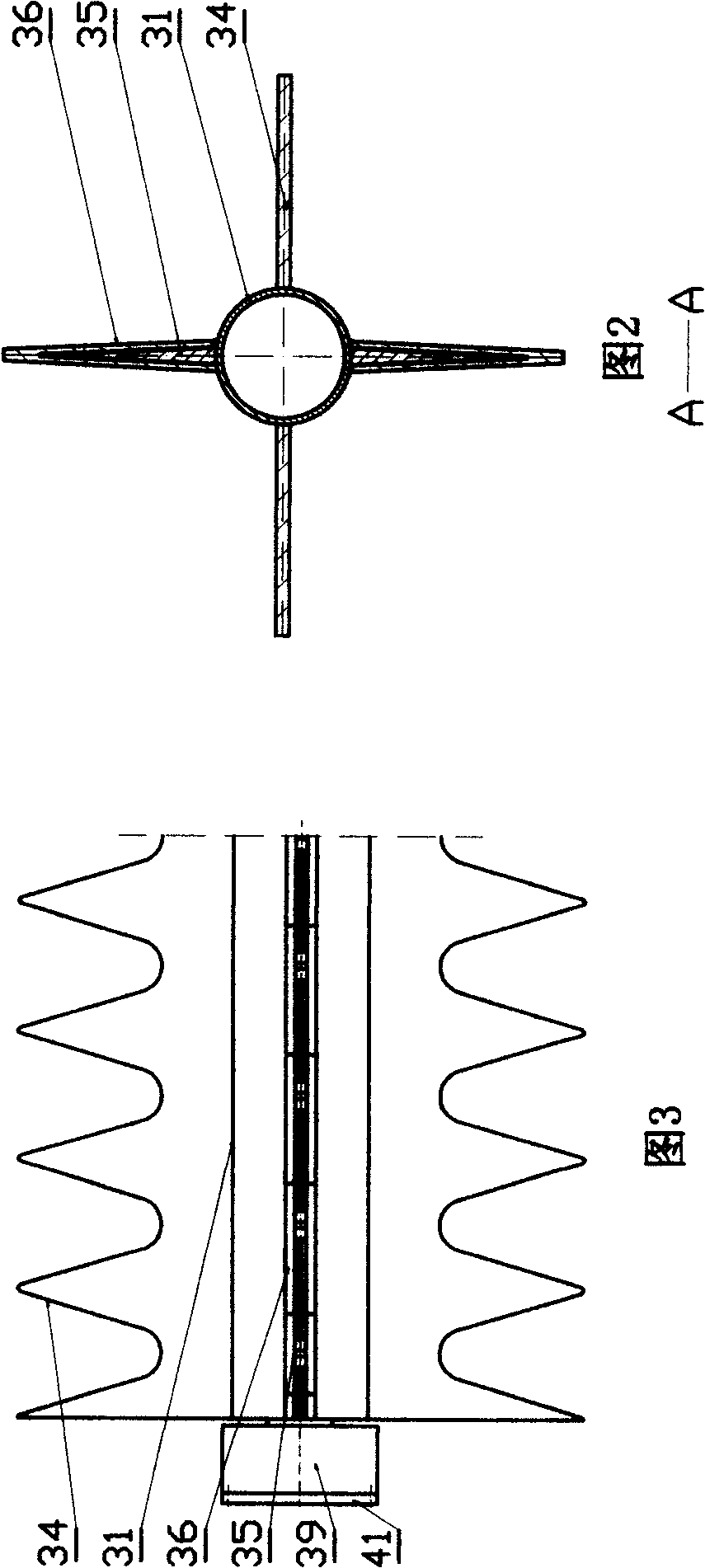

Paddy field harrow with cutting toothed plates

The invention discloses a paddy field harrow with cutting toothed plates. The paddy field harrow comprises two groups of rolling harrows, a power transmission box and main framework suspension plates. The two groups of rolling harrows are symmetrically arranged on two sides of the power transmission box, each group of rolling harrows comprises support-side circular plates, a support shaft, the corresponding cutting toothed plates and cutters, one end of the support shaft of each group of rolling harrows is connected with an output shaft of the power transmission box, the other end of the support shaft of each group of rolling harrows is mounted on a bearing block, the bearing blocks are mounted on the main framework suspension plates, the corresponding support-side circular plates are mounted at two ends of each support shaft, the corresponding cutting toothed plates which are uniformly arranged are arranged between the support-side circular plates of each group of rolling harrows in a fixedly connected manner, and the cutters are transversely uniformly distributed on the cutting toothed plates. The paddy field harrow has the advantages that the paddy field harrow can be divided into a front-rake paddy field harrow and a rear-rake paddy field harrow according to difference of relative welded positions and directions of cutting edges of the cutters on the cutting toothed plates, and the front-rake paddy field harrow and the rear-rake paddy field harrow can be selectively utilized according to difference of paddy field operation environments; the paddy field harrow is simple in structure, excellent soil crushing, pulping and green manure returning effects can be realized, agricultural requirements can be met by operation effects to a great extent, and accordingly the paddy field harrow has certain economical efficiency and practicality.

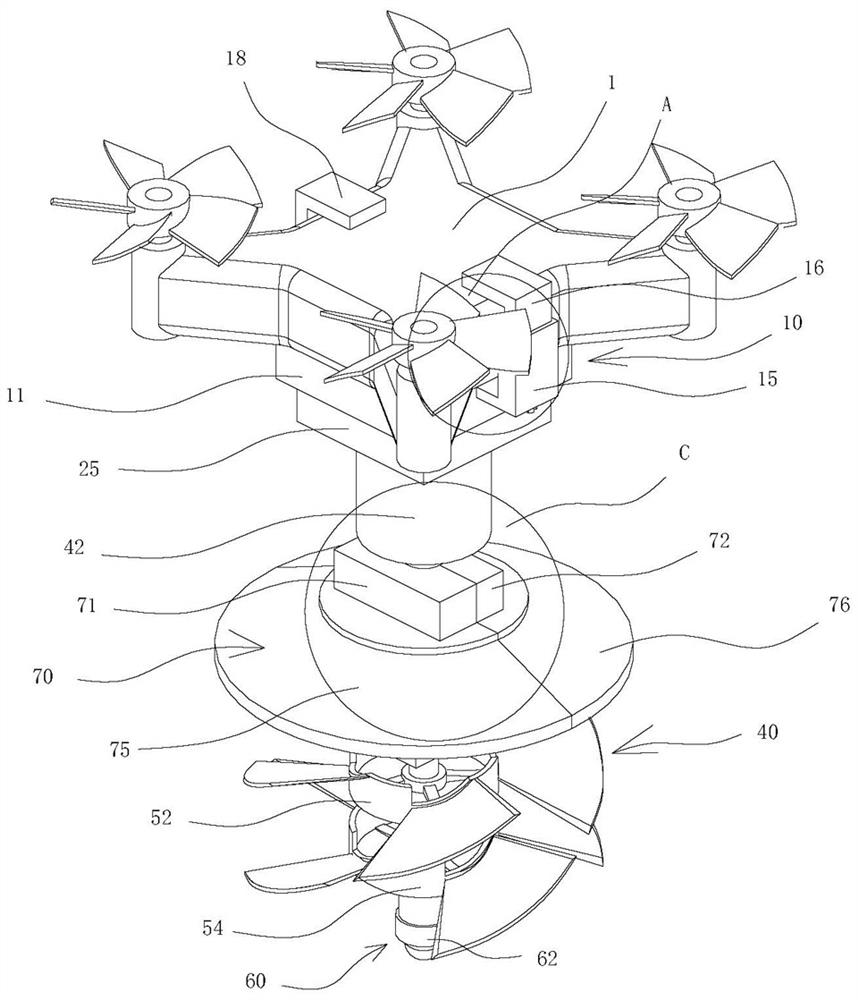

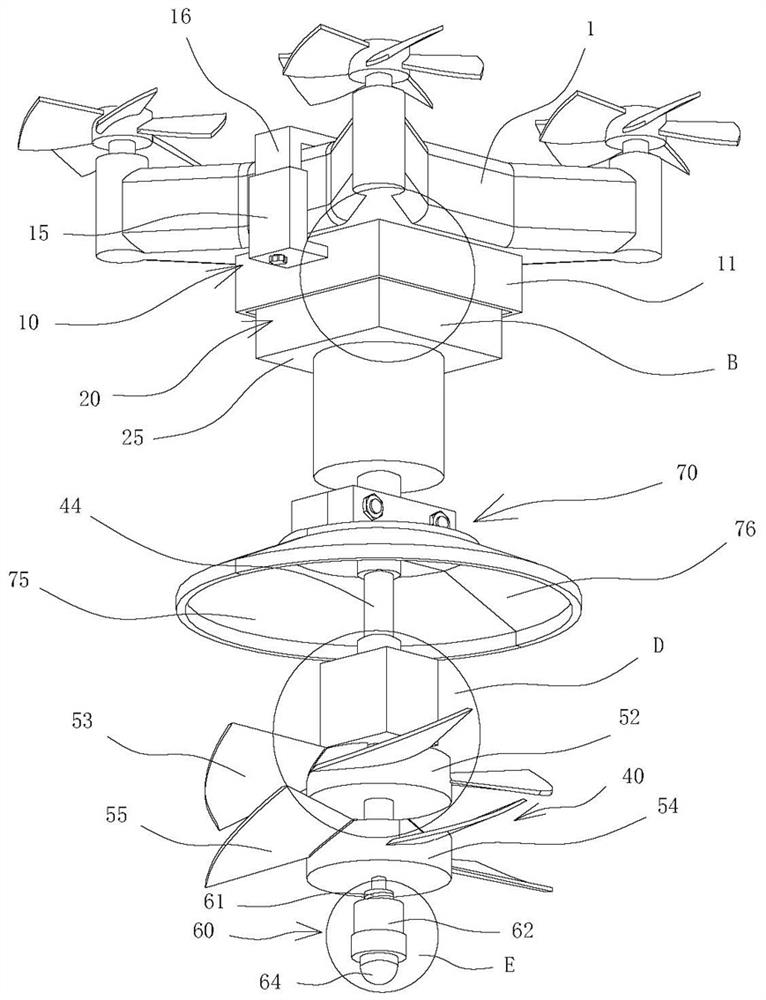

Lawn trimming device of unmanned aerial vehicle

ActiveCN111758370AFlexible connectionEasy to separateAircraft componentsMowersAgricultural scienceAgricultural engineering

The invention discloses a lawn trimming device of an unmanned aerial vehicle. The lawn trimming device comprises the unmanned aerial vehicle, wherein a clamping mechanism is arranged on the lower sideof the unmanned aerial vehicle; a balance mechanism for maintaining the level is arranged at the lower end of the clamping mechanism; a weeding mechanism is arranged at the lower end of the balance mechanism; an auxiliary mechanism for maintaining the height of the weeding mechanism is arranged at the bottom end of the weeding mechanism; and a material blocking mechanism is arranged at the upperend of the weeding mechanism. The lawn trimming device disclosed by the invention has the beneficial effects that upward airflow is generated by blades, and grass clippings are cut up by the second blade after rising, so that the grass clippings are convenient to rot on a lawn to provide nutrients for other crops, the grass clippings do not need to be cleaned by a user, and the labor intensity isreduced.

Owner:泰安正豪物业管理有限公司

Polyolefin dispersion compositions for making high vapor transport hydrophobic coatings

The present invention provides compositions for water vapor permeable hydrophobic coating comprising a blend of (i) a primary polyolefin dispersion of one or more large particle size polyolefins having a melting point of at least 95° C., and an average particle size of from 1 to 5 microns, and containing a volatile base and a 14 to 40 carbon long chain linear carboxylic acid dispersing agent, and (ii) a film forming second dispersion of one or more polymers having an average particle size of from 0.1 to 1.0 microns chosen from one or more polyolefins having a melting point from 50 to 90 ° C. further containing an at least partially neutralized olefin containing dispersing agent, one or more alkyl celluloses which further contain a plasticizer having a boiling point of 250° C. or greater and containing an at least partially neutralized olefin containing dispersing agent, and one or more acrylic emulsion polymers having a Tg of from 0 to 60° C. wherein the particle size ratio of the primary polyolefin dispersion to the second dispersion ranges from 3:1 to 29:1.

Owner:DOW GLOBAL TECH LLC

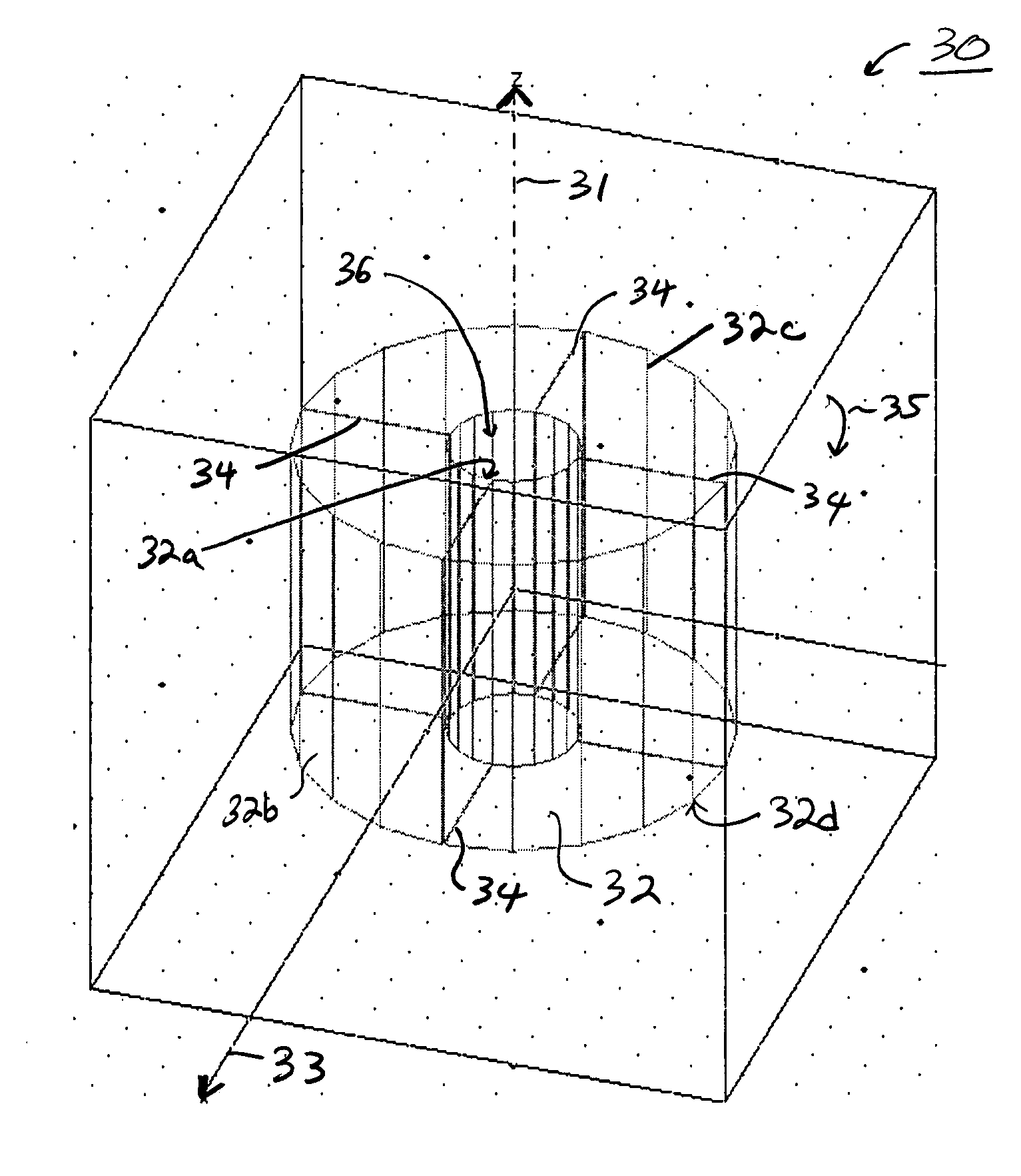

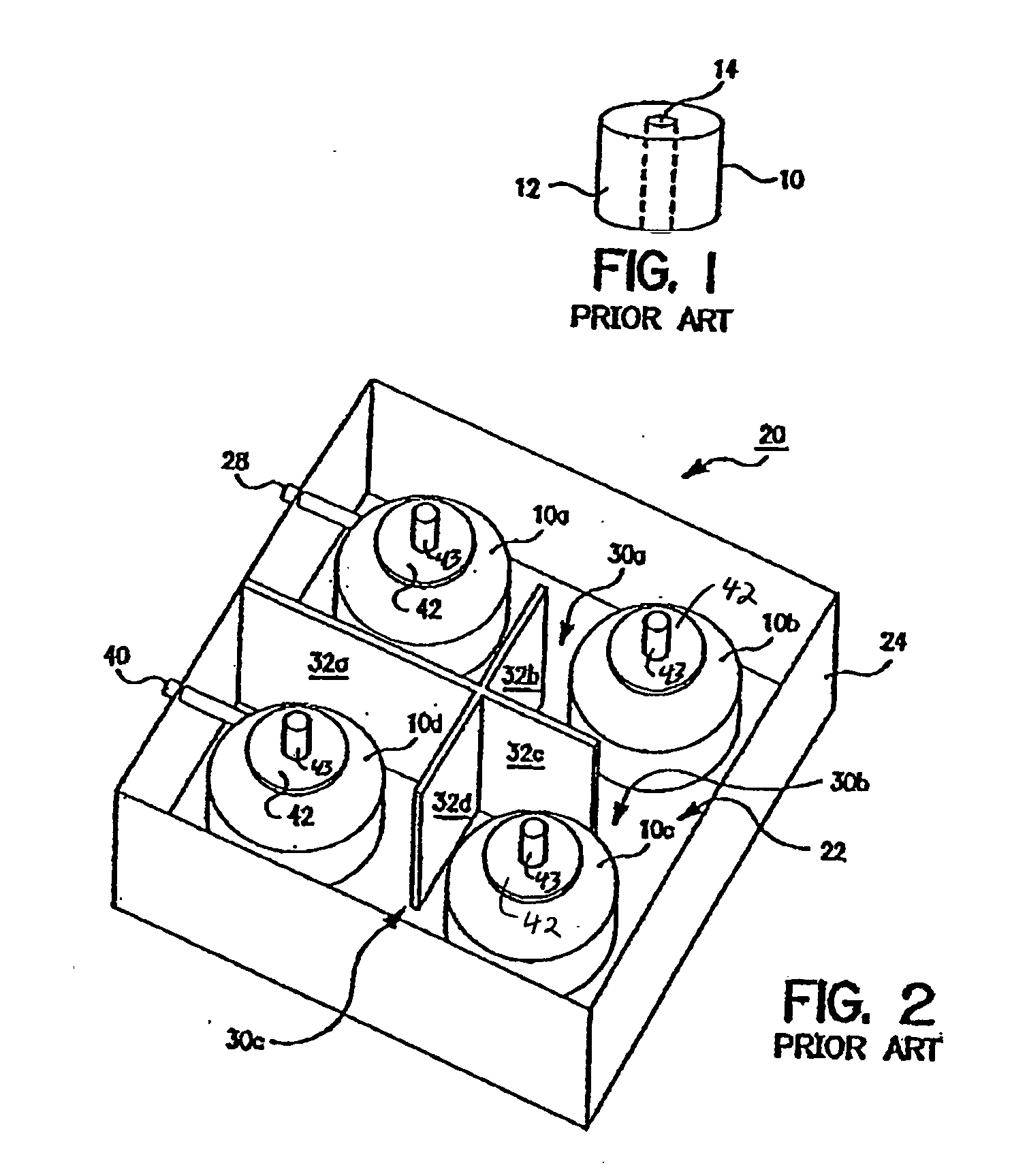

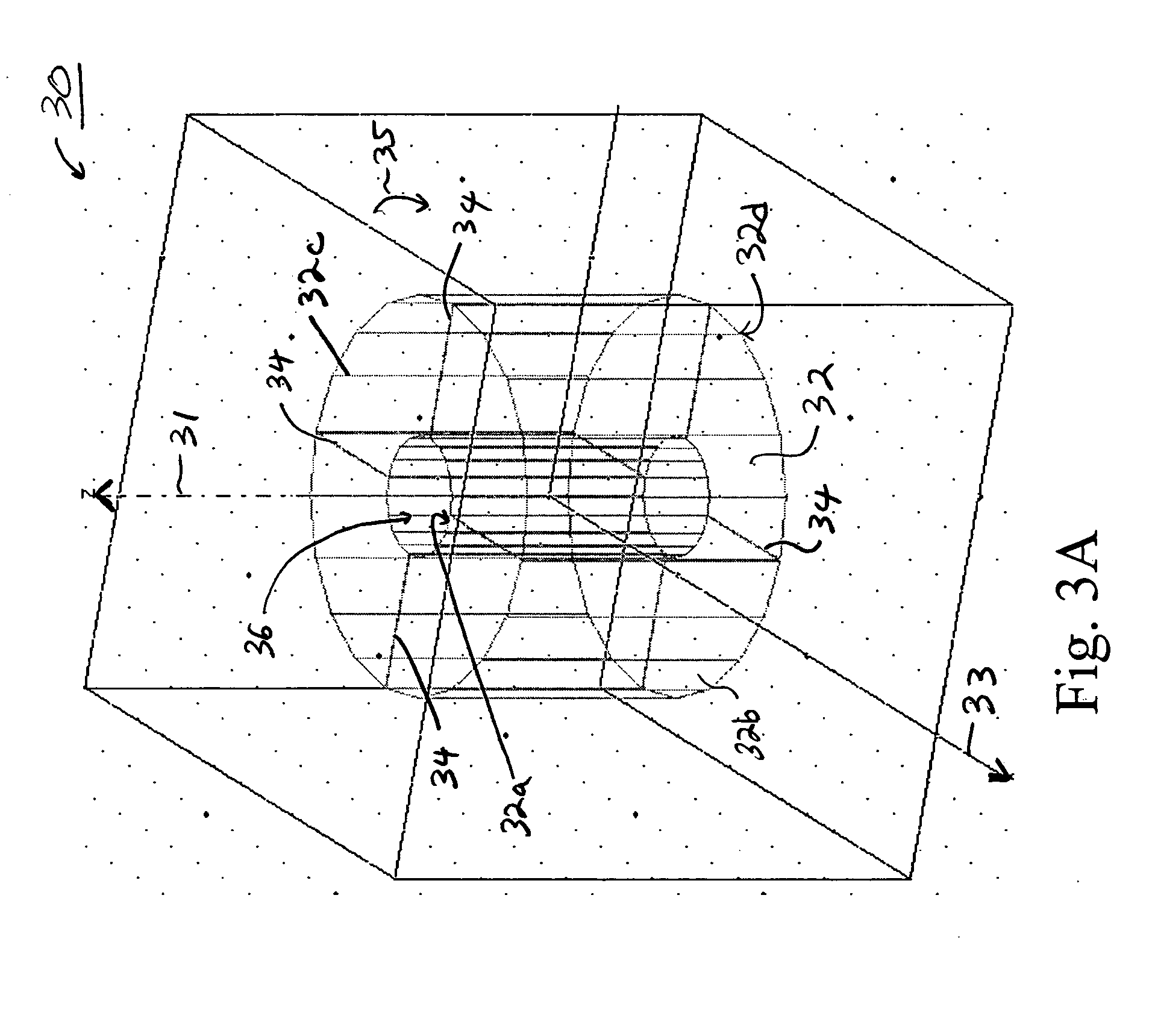

Slotted dielectric resonators and circuits with slotted dielectric resonators

InactiveUS20050237135A1Improving QIncreasing center frequency of resonatorResonatorsDielectric resonatorEngineering

In accordance with the principles of the present invention, a resonator puck is provided with one or more vertical and / or horizontal, radial slits that improve the quality factor, Q, of circuits constructed from the resonators. Preferably, the slits are very narrow and, more preferably, about 100 to 1000 atoms wide. In some preferred embodiments of the invention, the surfaces of the resonators that define the slit are left relatively rough and may even contact each other such that the slit is not of uniform thickness, but essentially comprises a plurality of pockets between the two portions of the resonator.

Owner:COBHAM DEFENSE ELECTRONICS SYST CORP

Rice plating method

InactiveCN108200844ALow oxygenGrowth inhibitionAnimal repellantsWeed killersGround temperatureSurface layer

The invention discloses a rice planting method. A layer of rice chaff is applied in the paddy field after transplanting, a water layer of 5-8 cm is maintained in the field to promote the fermentationof the rice chaff which can rapidly increase the ground temperature, the oxygen content of the surface layer is reduced, a higher ground temperature germination environment is created for weed seeds,simultaneously the growth of weed roots is inhibited, and the decay of aboveground parts is promoted to achieve the purpose of eliminating weeds.

Owner:田跃庆

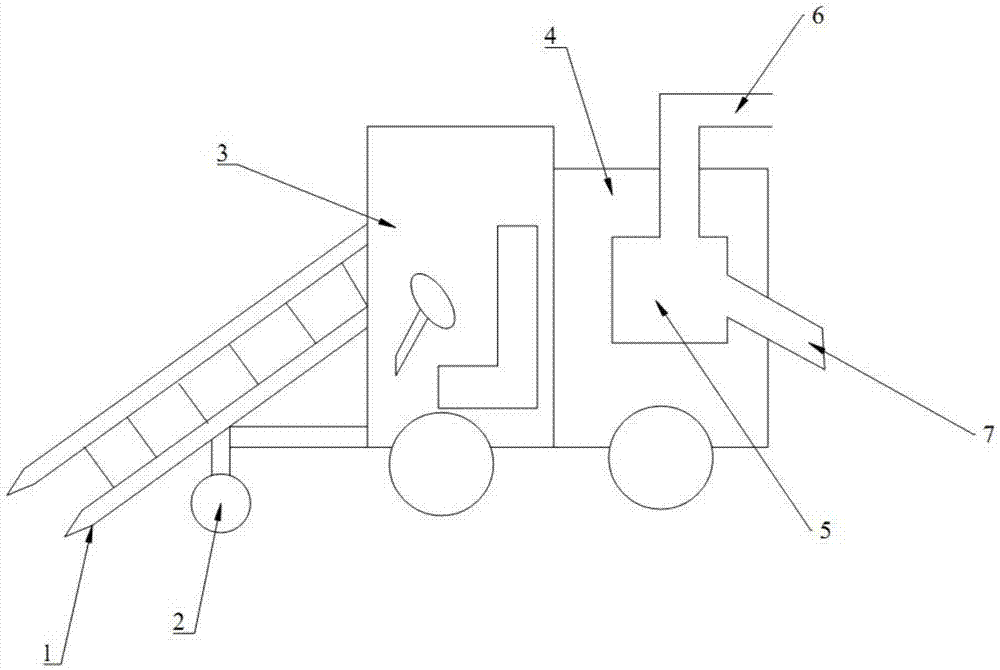

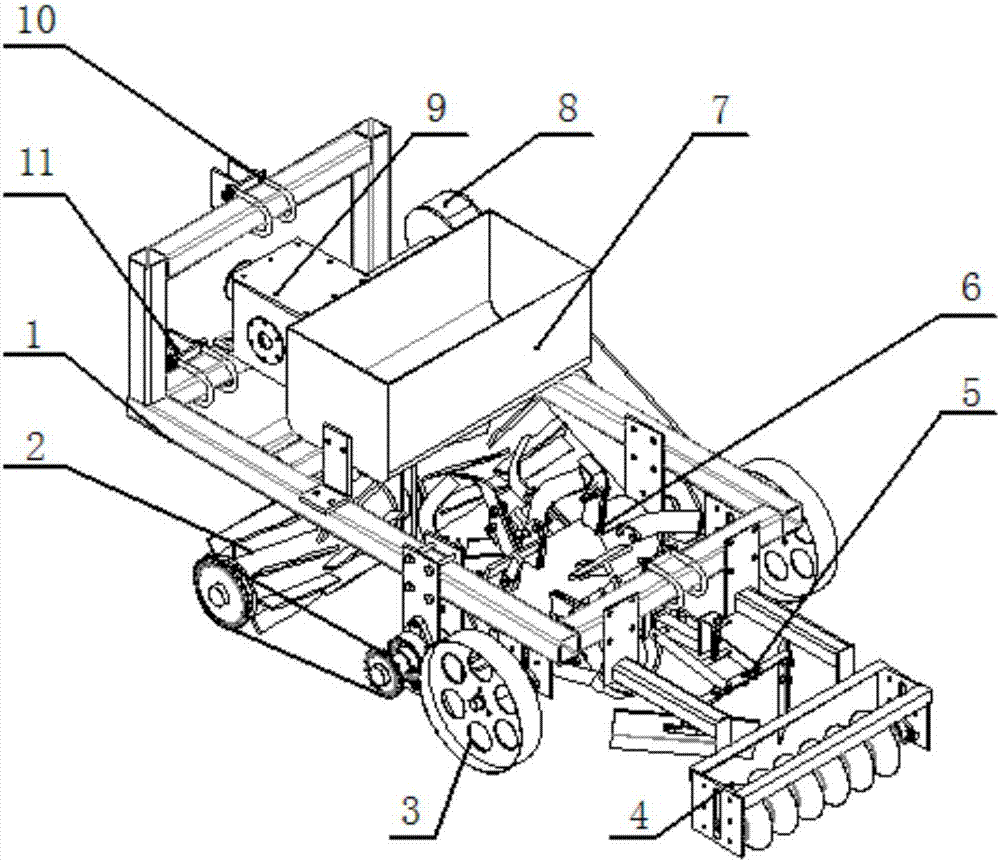

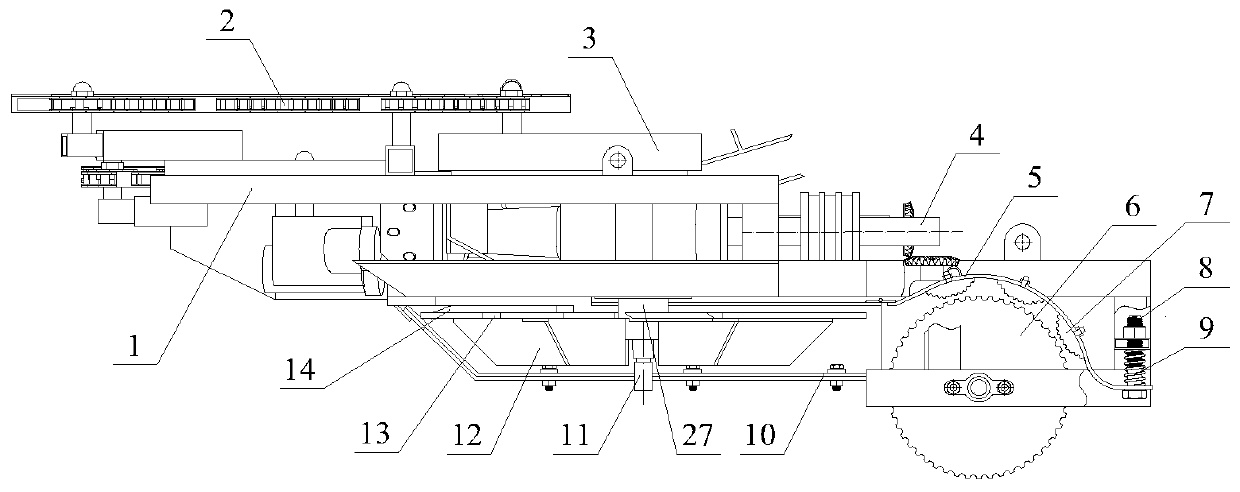

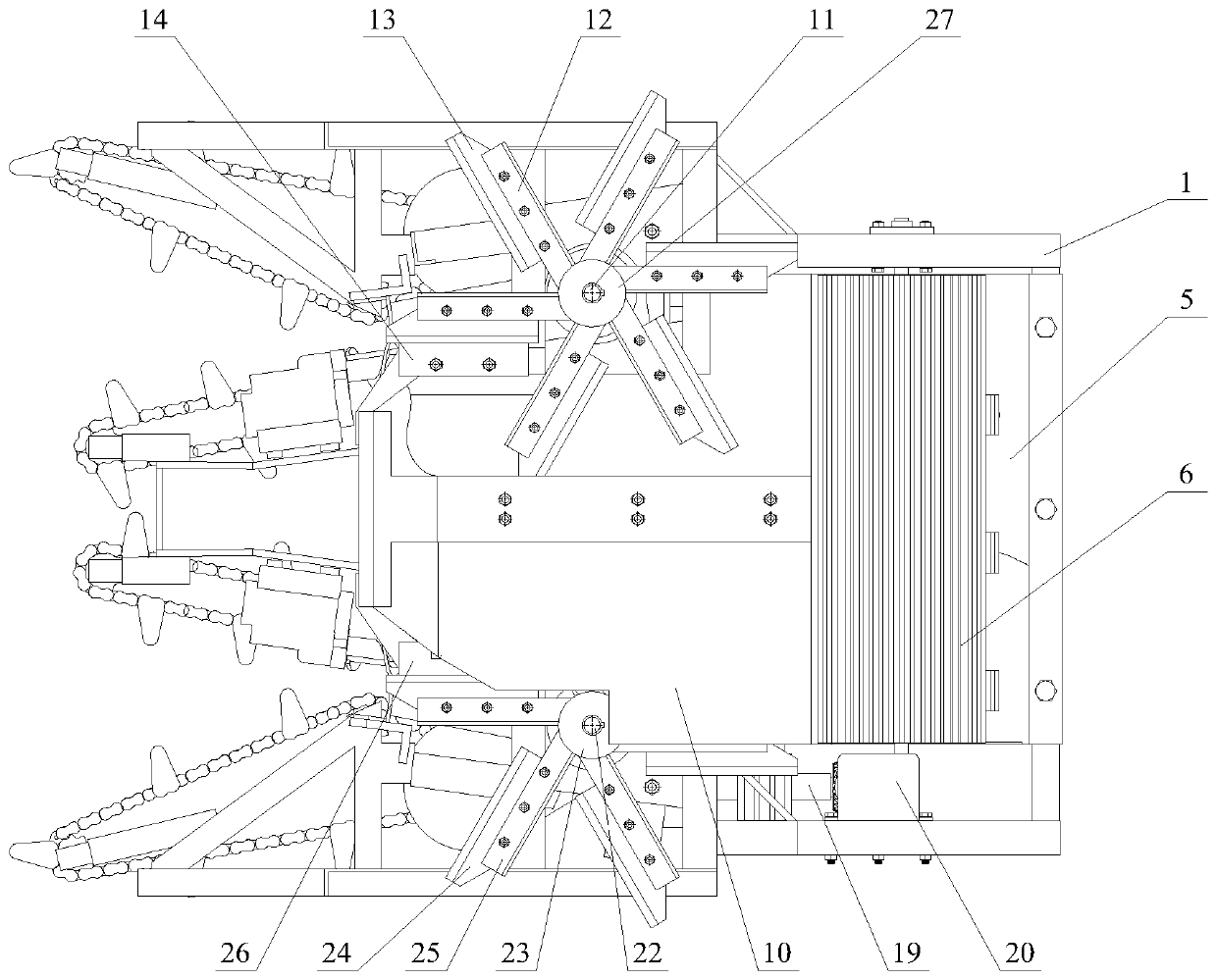

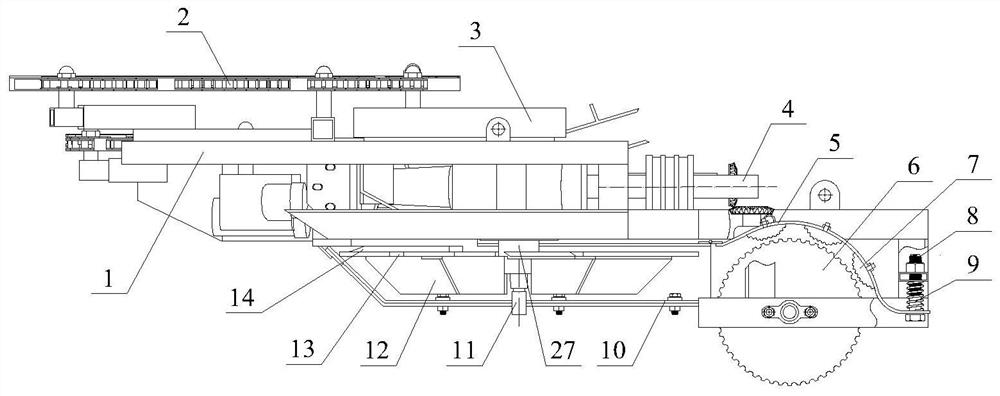

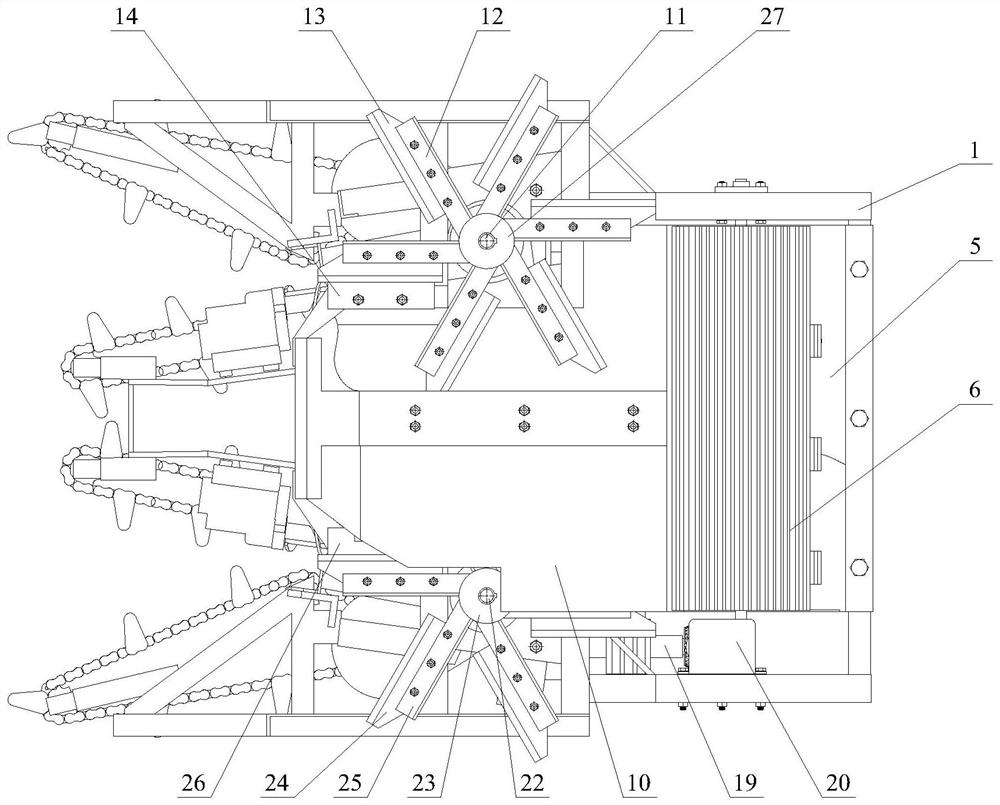

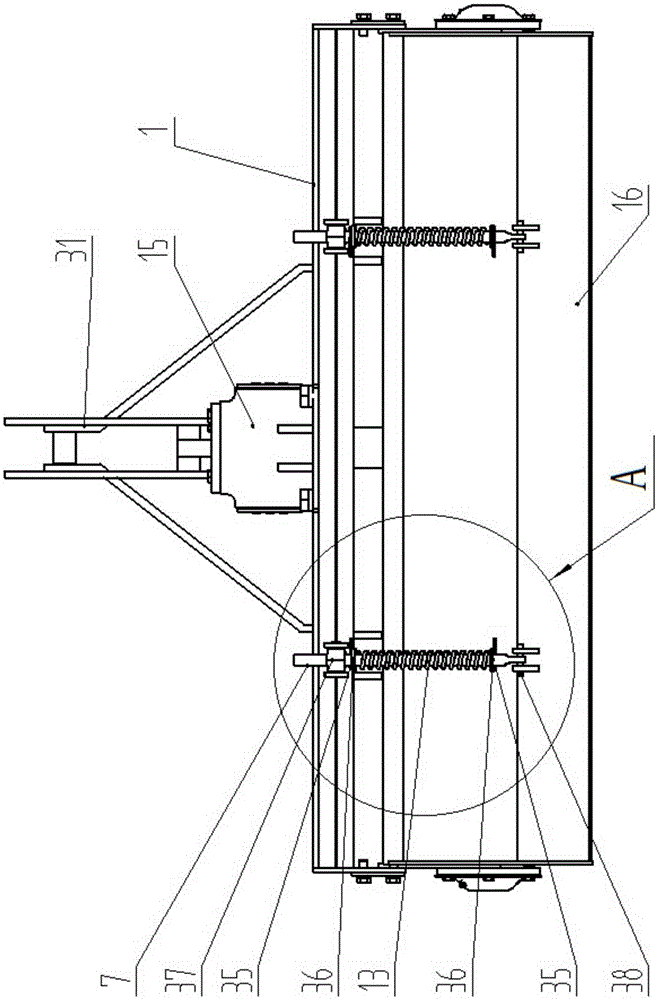

Peanut fruit-harvesting and straw-returning integrated machine

InactiveCN106912244AReduce cumbersomeConducive to decaySpadesCrop conditionersAgricultural engineeringOrganic fertilizer

The invention discloses a peanut fruit-harvesting and straw-returning integrated machine, belongs to the field of agricultural mechanical apparatuses, which can be used for solve the problem that the conventional peanut harvesters on a market cannot process leaves of peanuts. A soil loosening conveying device includes two vertical rods which are connected through conveying belts; bottom ends of the two vertical rods of the soil loosening conveying device are shovel-shaped; an upper end of the soil loosening conveying device is connected to one end of a fruit collection device through a hinge; a support wheel is arranged on a lower end surface of the soil loosening conveying device; the support wheel is connected to a driving compartment through a connection rod; the driving compartment is of a square structure; a root and stem smashing machine is arranged in the fruit collection device; an air outlet is formed in the upper end of the root and stem smashing machine; the air outlet communicates with the upper end of the root and stem smashing machine through welding; a discharging opening is formed in one side surface of the root and stem smashing machine, and the discharging machine is inclined; and one end of the discharging opening communicates with one side surface of the root and stem smashing machine through welding. The integrated machine can achieve fruit harvesting and smashing at the same time, is conductive to rot of returned straw, thereby providing a high efficient organic fertilizer for later crops.

Owner:广州成航信息科技有限公司

Efficient harvesting machine for myotonin

InactiveCN107535178AImprove harvesting efficiencyEasy to sit and harvestMowersEngineeringConveyor belt

The invention discloses an efficient harvesting machine for myotonin. The harvesting machine comprises a harvesting table, multiple feeding ports are formed in the harvesting table, multiple rows of smashing wheels are arranged inside the feeding ports and fixed to rotating shafts inside the harvesting table, the two ends of each rotating shaft are fixed to the top end and the bottom end of the harvesting table respectively, a conveyor belt is arranged on the lower sides of the smashing wheels at the top end inside the harvesting table, and is communicated with the inlet end of a threshing boxthrough a power roll, a threshing roll is arranged inside the threshing box, multiple cutters are evenly arranged on the outer side wall of the threshing roll and are perpendicular to the tangentialline of the threshing roll, a threshing box discharging port is formed in the bottom end of the threshing box, one side of the lower end of the threshing box discharging port is connected with the inlet end of a lifter, and a discharging port is formed in the outlet end of the lifter. Cost for labor investment is reduced; due to adopted mechanical harvesting, working efficiency is greatly improved, meanwhile, resources are saved, and the environment is protected.

Owner:贵州安顺顺达机械服务有限公司

Impurity removal and cutting device for corn grain machine

InactiveCN107930753ASmooth rotationEasy to transportDirt cleaningGrain treatmentsEngineeringImpurity

The invention discloses a miscellaneous and chopping device for a corn grain machine, which comprises a feeding pipe, the left end of the upper surface of the feeding pipe is provided with a first through hole, and the upper surface of the feeding pipe corresponding to the first through hole is provided with an impurity removing device. device, the left end of the lower surface of the feeding pipeline is provided with a second through hole, and the second through hole is located on the right side of the first through hole, and the lower surface of the feeding pipeline corresponding to the second through hole is provided with a collecting device, so The right end of the feeding pipeline is provided with an extruding device, and the front end of the extruding device is provided with a driving mechanism, the right end of the feeding pipeline is provided with a collecting funnel, and the outlet of the collecting funnel is provided with a conveying pipe. The corn grain machine discharge and chopping device can transport the corn with impurities, can screen and collect the corn grains, and can also extract, squeeze and crush the impurities in the corn grains, which is convenient for the rot of impurities and convenient The growth of crops is simple and easy to use.

Owner:何欣

Pre-harvest sweet persimmon preservative

InactiveCN103609554ASimple preparation processLow costBiocideDead plant preservationThiophanate-methylPreservative

The invention discloses a pre-harvest sweet persimmon preservative. The pre-harvest sweet persimmon preservative is characterized in that natamycin, sec-butylamin and thiophanate-methyl are taken as main agents, one or more components of methyl pyrilamine, chlorothalonil, trichloroisocyanuric acid, sodium dichloroisocyanurate, potassium dichloroisocyanurate, dichlord isocyanurice acid, sodium dichloroisocyanurate, potassium dichloroisocyanurate, sodium chlorite and potassium chlorite are taken as strengthening components to uniformly mix according to a certain proportion. An application method of the pre-harvest sweet persimmon preservative comprises the following steps of: diluting the preservative and water in a weight ratio of 1:100; and spraying the preservative on carpopodium within 24 hours-48 hours before harvesting the sweet persimmons. The pre-harvest sweet persimmon preservative disclosed by the invention is simple in preparation process, low in cost and less in investment. Moreover, the pre-harvest sweet persimmon preservative is convenient to apply, and convenient to operate and apply in production practice. Besides, the pre-harvest sweet persimmon preservative has effects of reducing mildew and decay in storage and transportation of the sweet persimmons, delaying ageing, and keeping the original quality, and further has characteristics of being safe, efficient, free from residues, and good in freshness-keeping effect.

Owner:BAOSHAN YINGSHANHONG FRUIT & VEGETABLE DEV

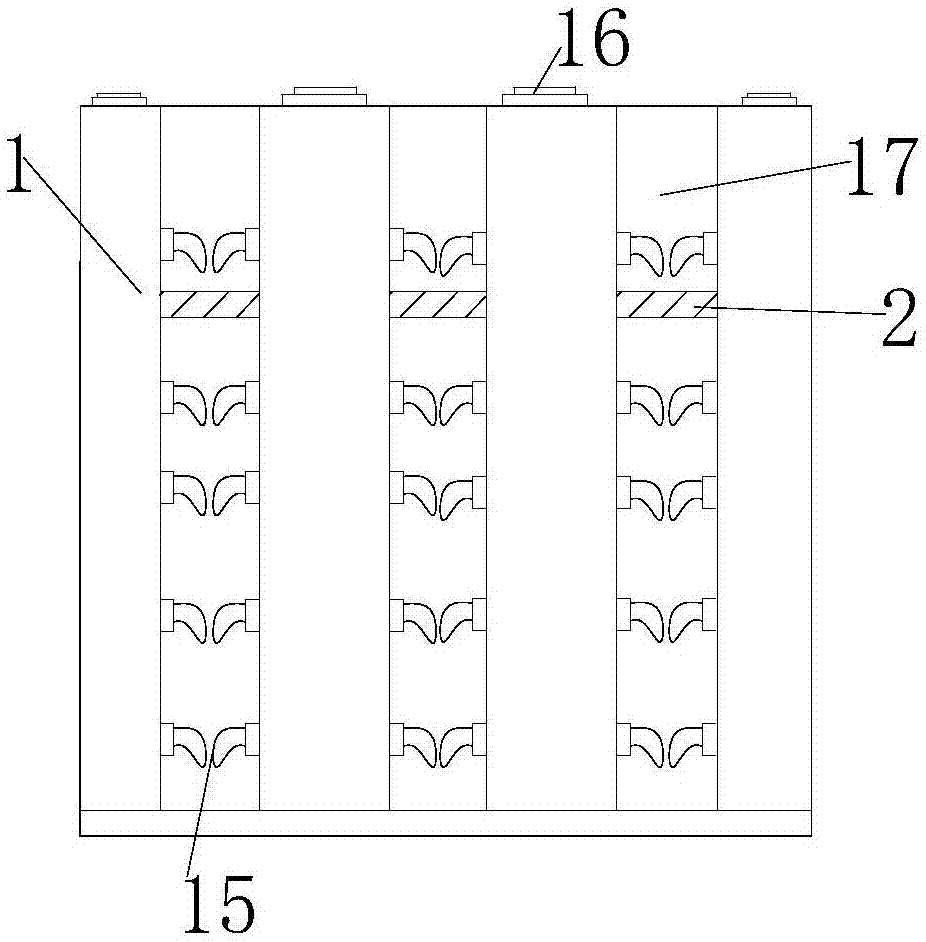

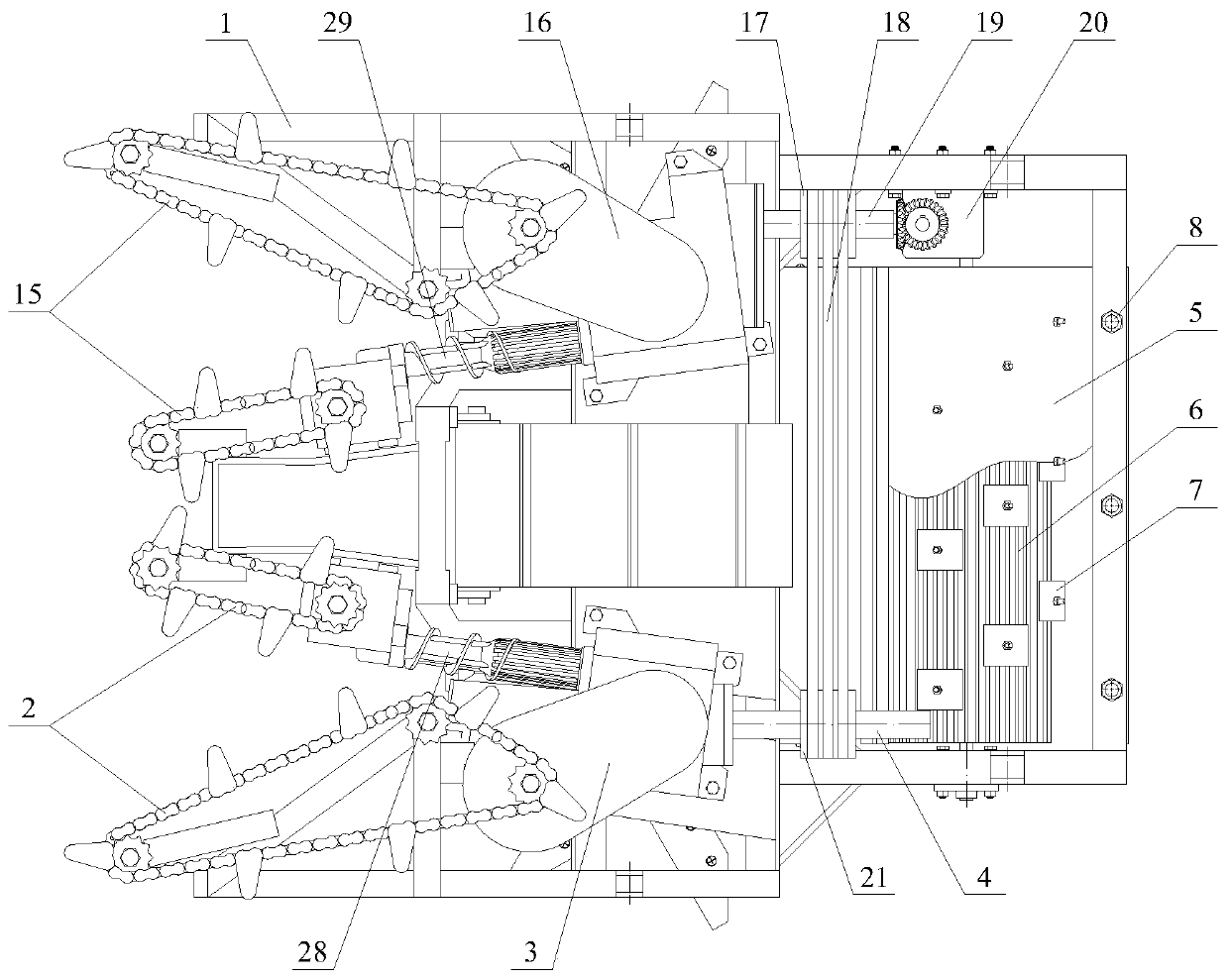

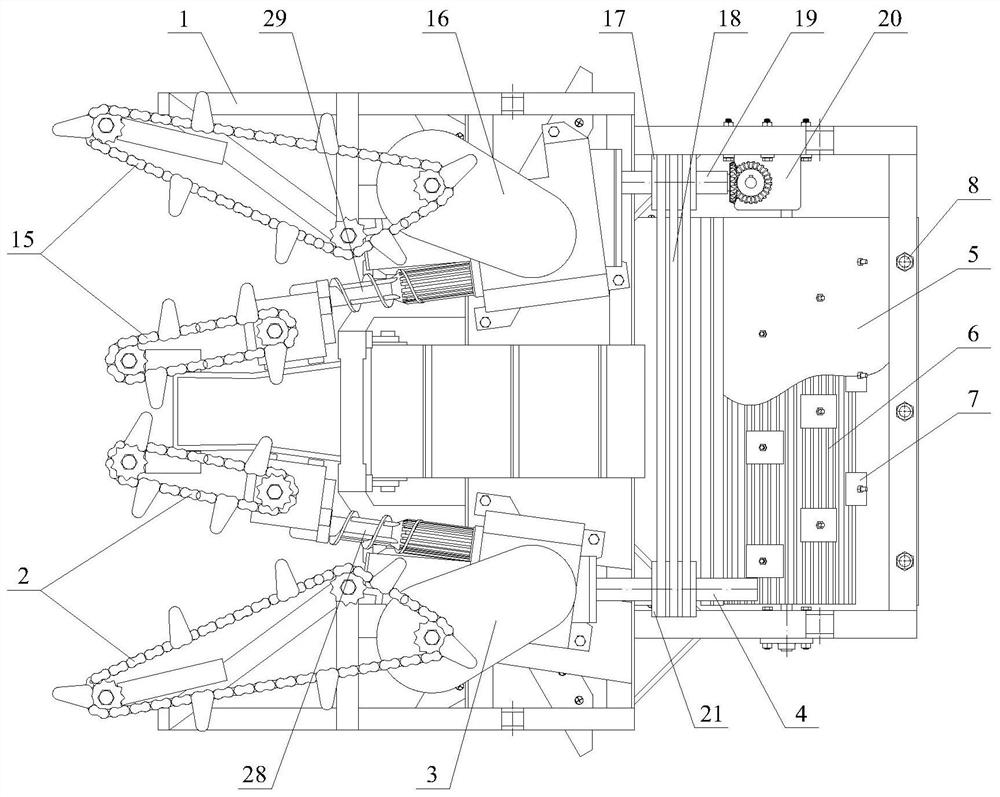

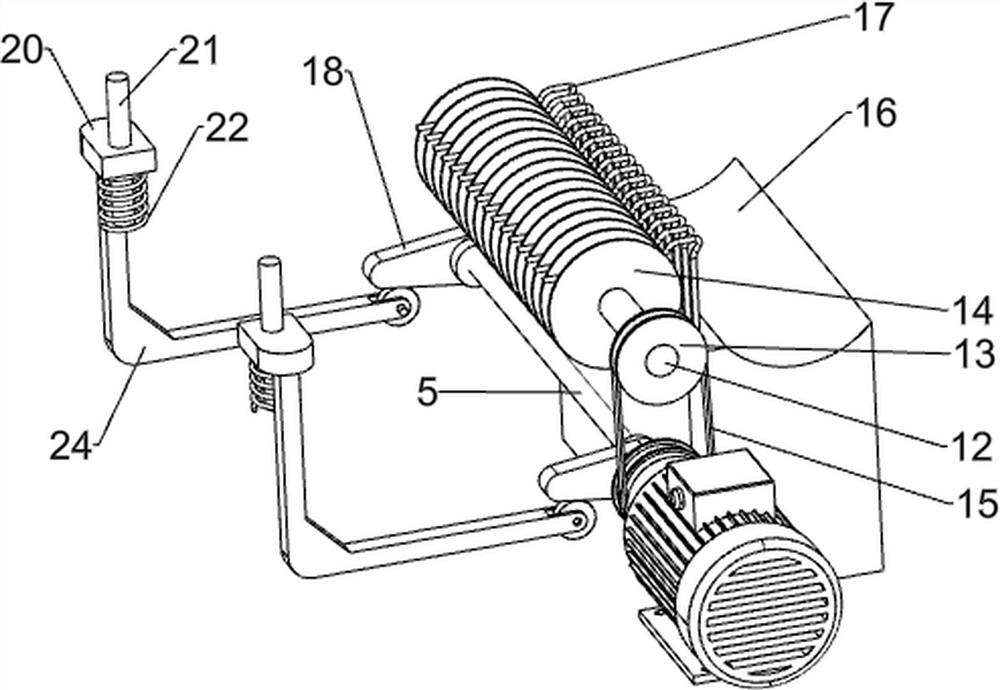

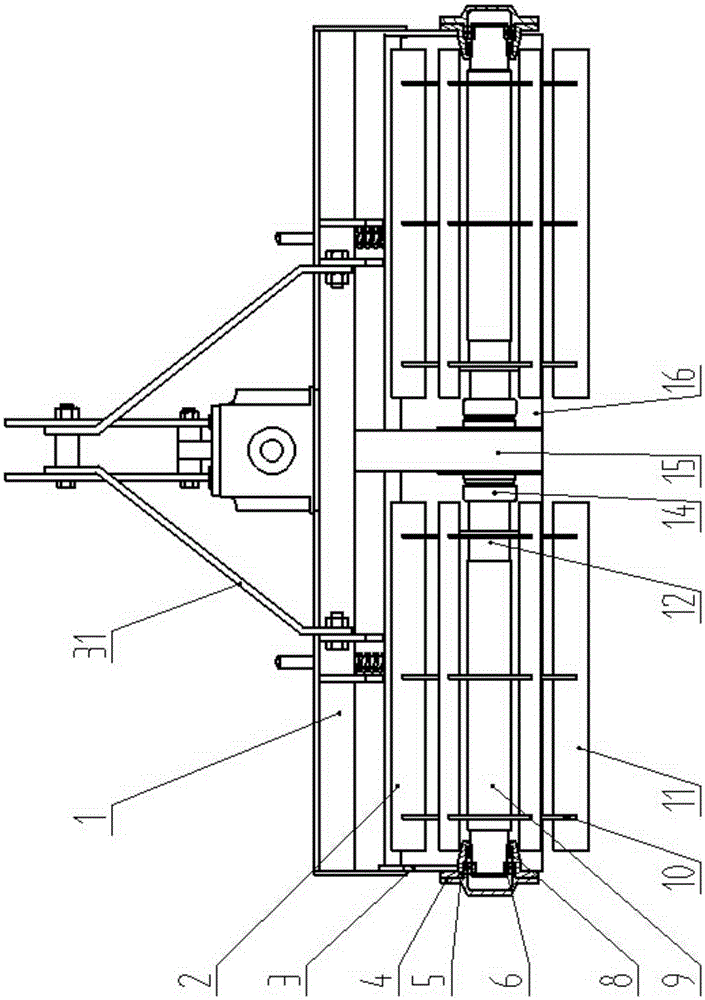

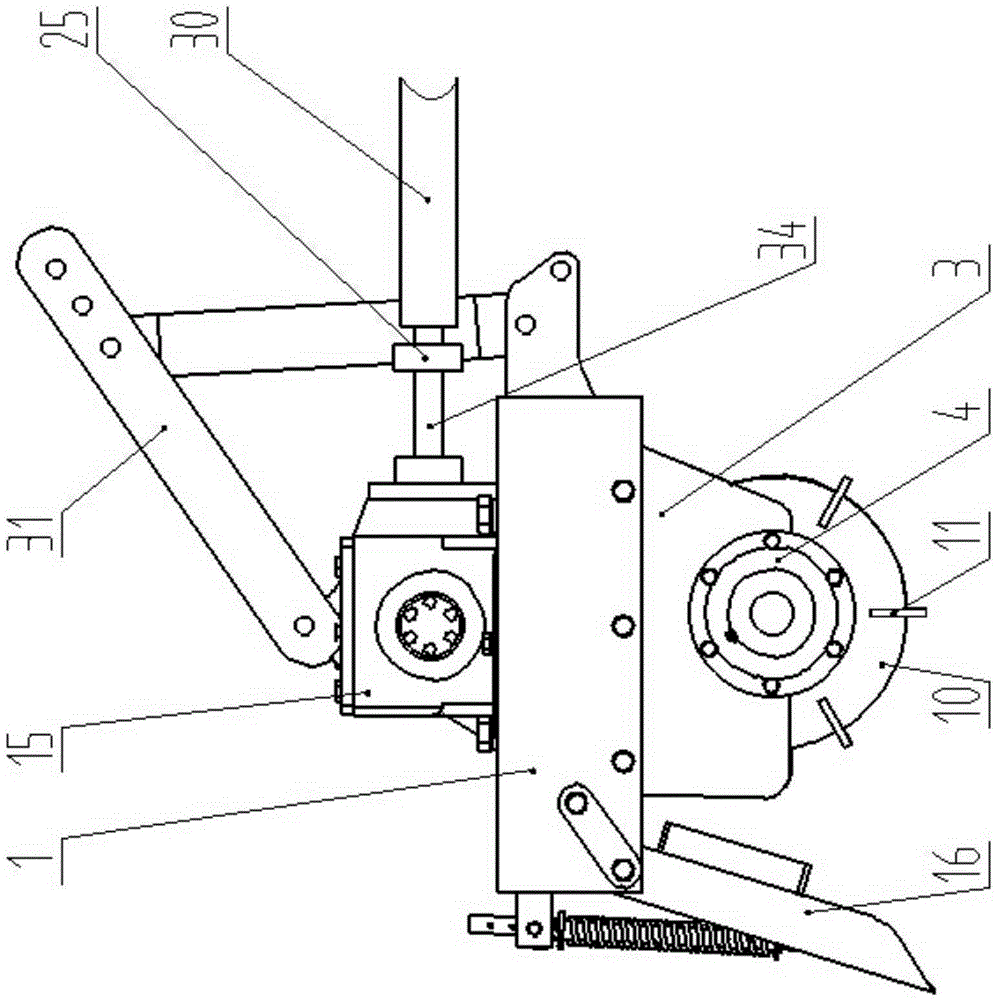

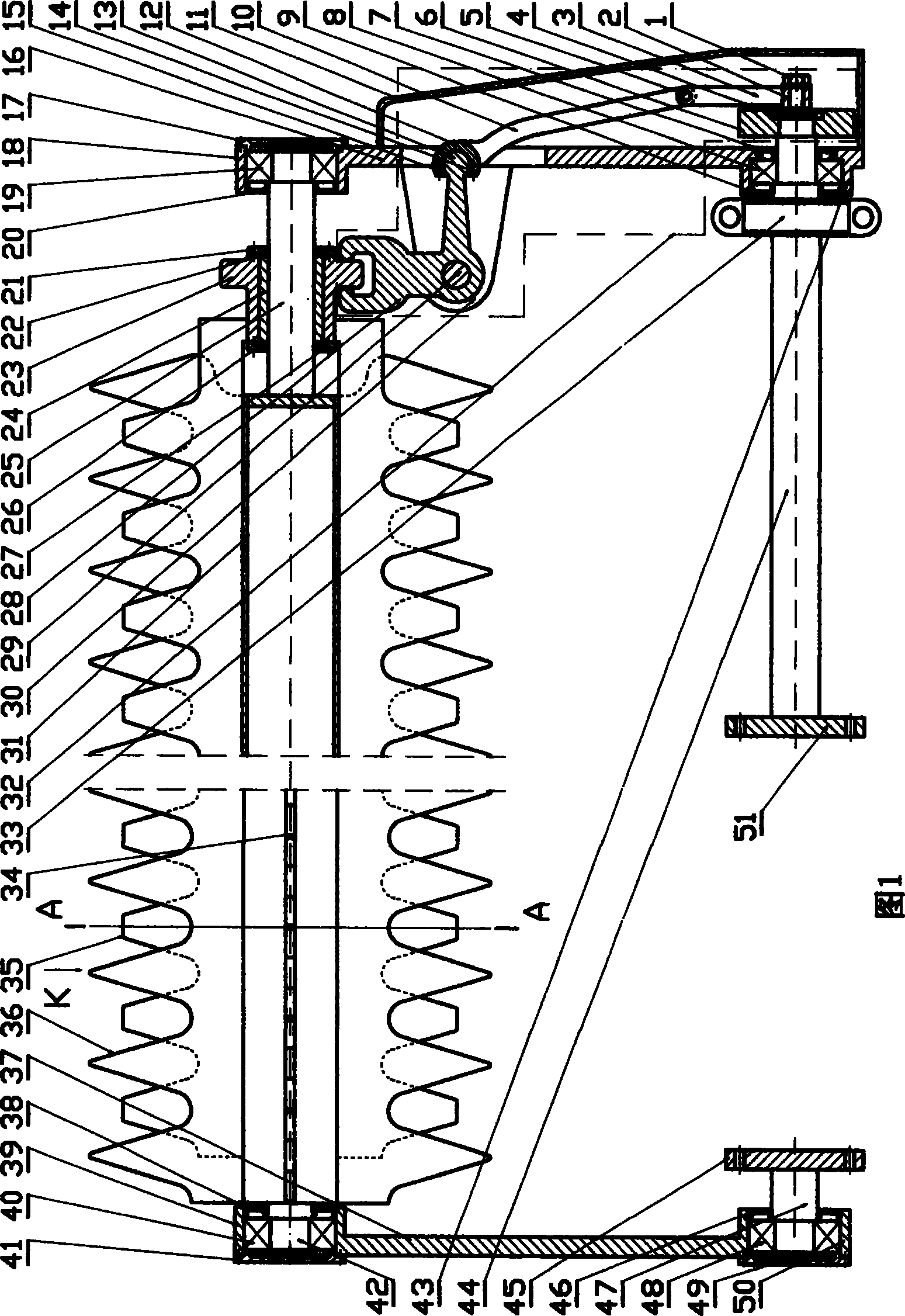

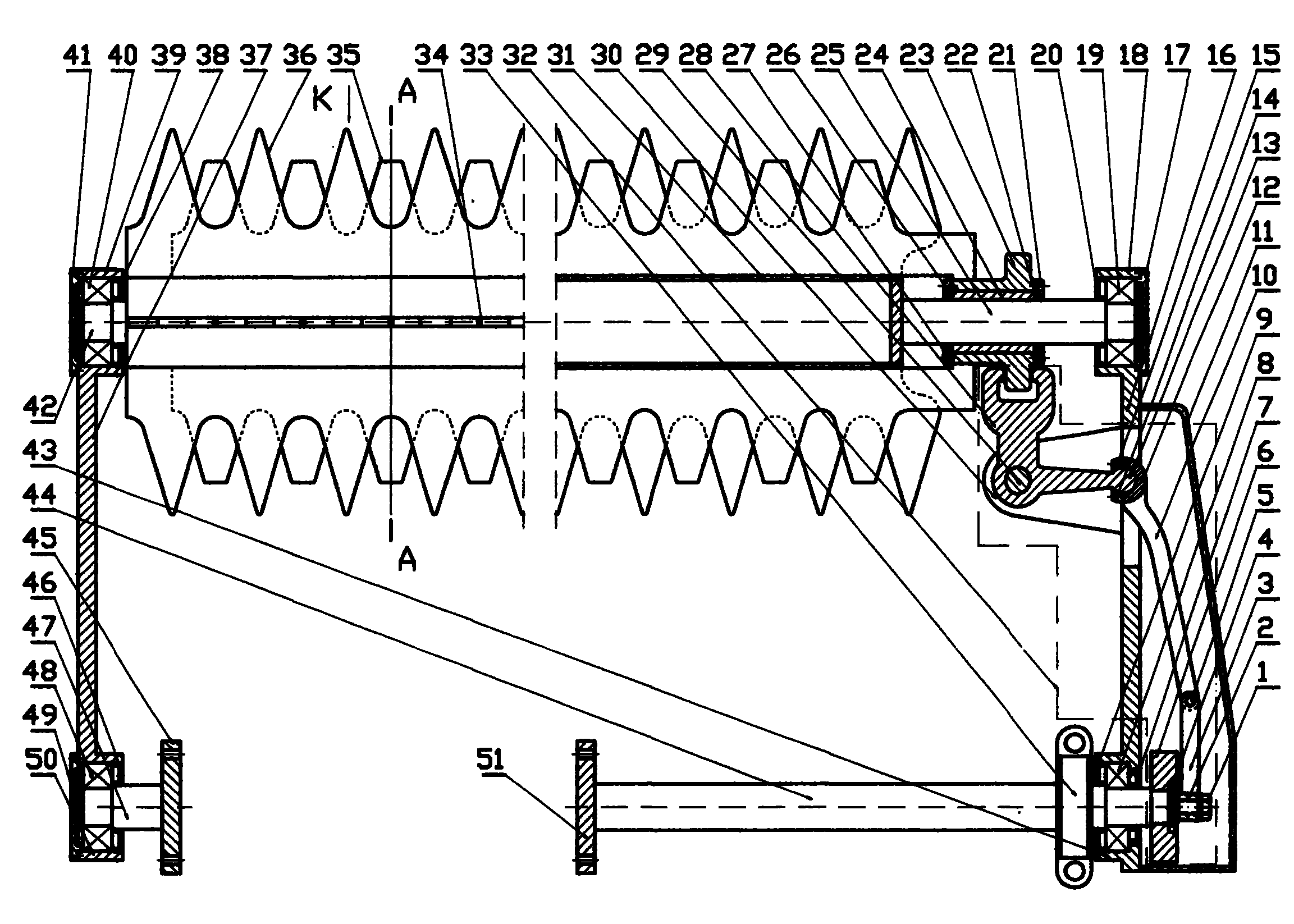

Wide-ridge double-line straw deep burying returning machine

ActiveCN106954431ADeep burialIncrease organic matterCrop conditionersMowersSoil organic matterAgricultural engineering

The invention provides a wide-ridge double-line straw deep burying returning machine and belongs to the technical field of agricultural machinery. The wide-ridge double-line straw deep burying returning machine comprises a rack, a gearbox, a drive device as well as a straw collecting device, a chemical box device, a burying device, a soil covering device and a pressing device which are mounted on the rack from a working front end to a working rear end sequentially, wherein the straw collecting device is formed by symmetrically connecting two groups of spiral rollers through connecting shafts, the connecting shafts are fixed on the rack through connecting plates, each group of spiral rollers are formed by symmetrically and obliquely arranging two groups of blades, and straw and weeds are cutup and collected from two sides to the middle; a rotary shaft tube of the burying device is connected with an output shaft of the gearbox through the drive device and is in drive connection with the straw collecting device, a rotary spade blade of the burying device is arranged in a furrow, and chemical discharge devices of the chemical box device are arranged behind the straw collecting device. The wide-ridge double-line straw deep burying returning machine has the advantages that stubble cleaning, straw collecting, burying, pressing and other work can be completed simultaneously in a working process, deep burying returning of straw is realized, soil fertility is improved, and soil organic matter is increased.

Owner:SHENYANG AGRI UNIV

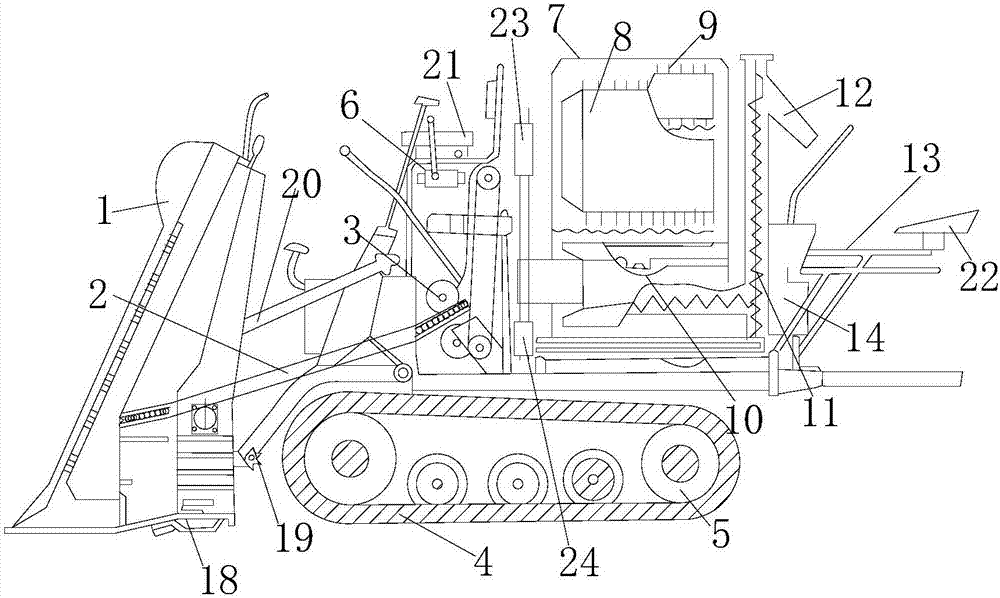

Standing type machine for smashing and rubbing corn stalks and returning corn stalks to field

The invention relates to a standing type machine for smashing and rubbing corn stalks and returning the corn stalks to field and belongs to agricultural machinery. The machine comprises a corn stalk guiding mechanism composed of poking chain groups and stem pulling rolls; a corn stalk cutting and smashing mechanism composed of moving knifes, fixed knifes, material conveying side plates and knife hubs; a rubbing, squeezing and crushing mechanism composed of a tooth-type rubbing roll, tooth-type rubbing blocks, a roll shield plate, a rubbing gap adjusting bolt group and a pressure spring; and apower driving system composed of an external power input shaft, a driving belt pulley, a driven belt pulley, a driving belt, a transfer shaft, a gear box, a reversing driving gear box, knife hub driving shafts and knife hubs. The machine has the beneficial effects that through the combined compound operation mode of cutting, smashing, squeezing, tearing, rubbing and crushing the corn stalks, the quality of smashing the corn stalks and returning the corn stalks to field is increased, the rot and the degradation of the corn stalks are benefitted and the advantages of returning the corn stalks tofield is fully played; and the machine is novel and reasonable in structure, good in operating quality, high in efficiency and reliable in use.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

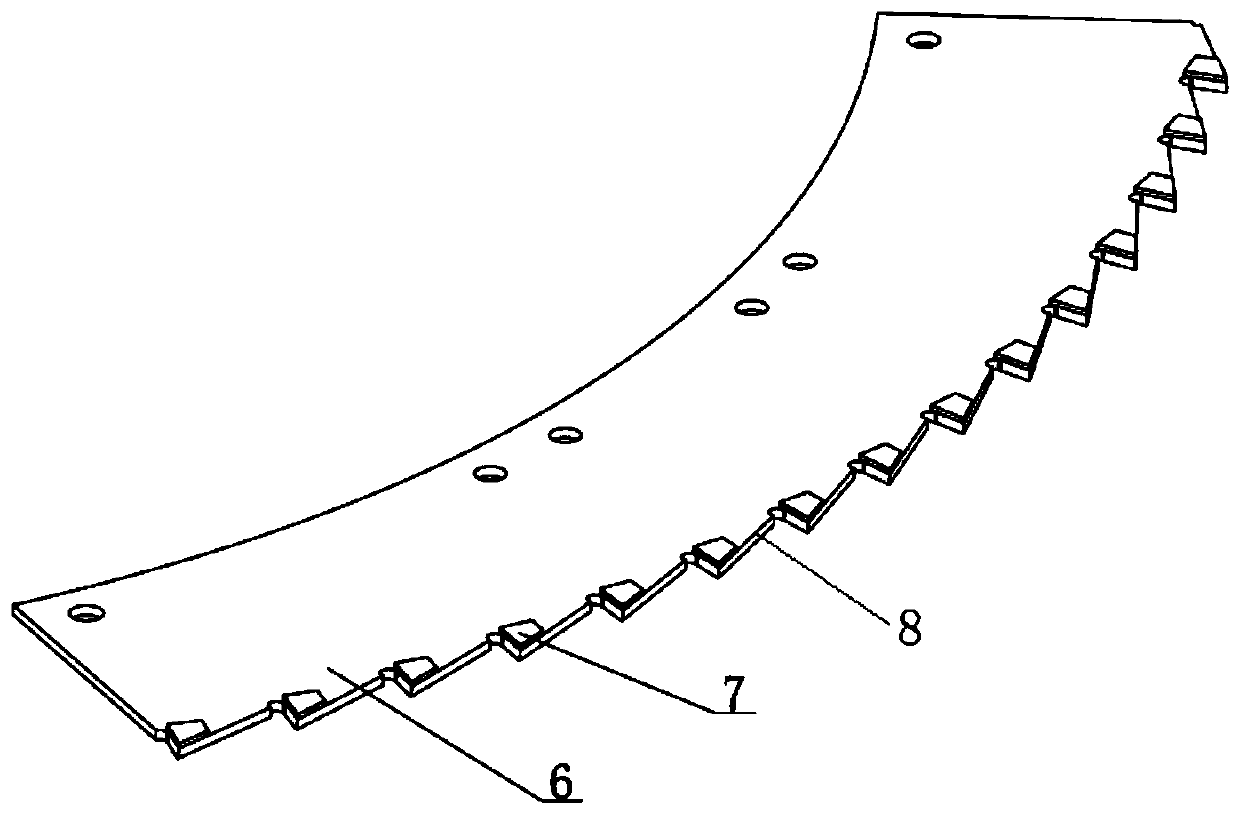

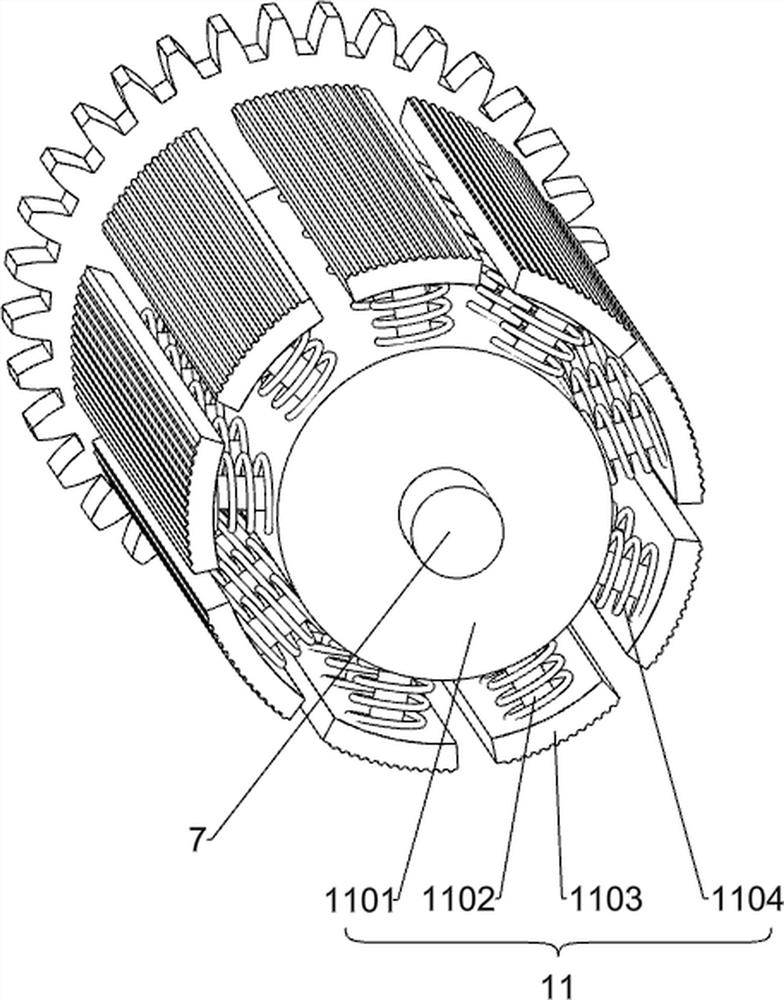

Silage maize harvester, and cutting tool and cutting cutterhead for silage maize harvester

The invention discloses a silage maize harvester, and a cutting tool and a cutting cutterhead for the silage maize harvester. The cutting tool comprises a cutting tool body in the shape of a fan ring.A toothed structure is arranged at the working end of the outer edge of the fan ring of the cutting tool body. A blocky cutting blade is arranged on the upper surface of the tip of each tooth of thetoothed structure, and the hardness of each cutting blade is greater than that of the cutting tool body to achieve automatic blade sharpening of the cutting tool during operation. During long-term operation of the cutting tool, the cutting tool body wears rapidly, the cutting blades wear slowly to naturally form cutting blades of cutting portions, and accordingly, automatic blade sharpening is achieved; the wear resistance and sharpness durability of the cutting tool are improved, and operation power consumption of the silage maize harvester is reduced.

Owner:SHANDONG ACADEMY OF AGRICULTURAL MACHINERY SCIENCES +1

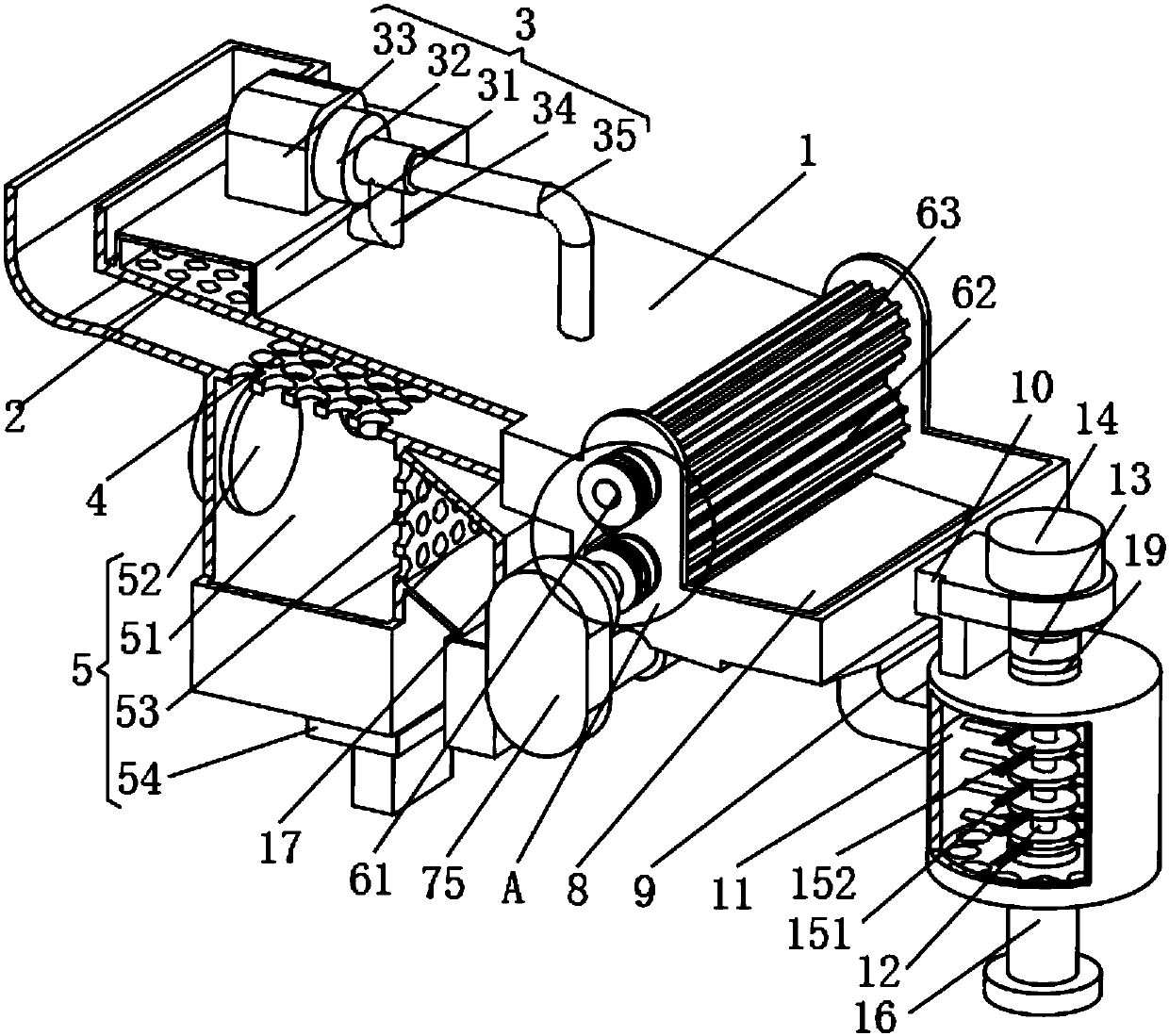

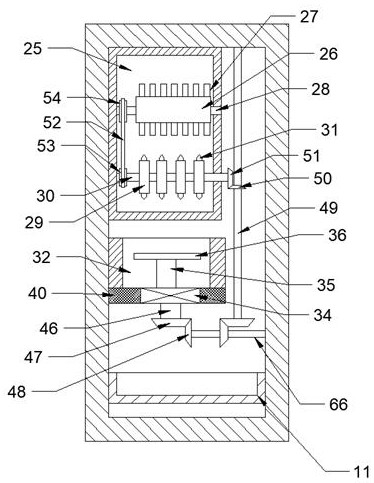

Straw smashing and throwing device

InactiveCN112136483APrevent wandering aroundConducive to decayUsing liquid separation agentMowersAgricultural scienceAgricultural engineering

A straw smashing and throwing device comprises a straw smashing and throwing device body. A straw connecting channel is fixedly arranged on the upper end face of the straw smashing and throwing devicebody, a drying layer is fixedly arranged on the periphery of the wall face of an inner cavity of the straw connecting channel, and an air outlet pipe is fixedly arranged on the upper end face of thestraw connecting channel. A smashing chamber is fixedly arranged on the front wall surface of an inner cavity of the straw smashing and throwing device body. According to the straw smashing and throwing device, straw collected during harvesting can be smashed, in the smashing process, the straw is cut up and then ground into powder, and in this way, the straw can be decomposed into nourishment byland as soon as possible; and in the discharging process, a throwing device is used for throwing out the powder to enable the powder to be evenly thrown into the land, water is sprayed to the powder to prevent the powder from drifting around in the throwing process, after the powder is thrown out, the powder is buried in the soil through a later ploughing device, the straw powder returning to theland is better rotted, and efficient organic fertilizer is provided for subsequent crops.

Owner:广州尼为亚科技有限公司

Standing corn stalk crushing, kneading and returning machine

The standing corn stalk crushing, kneading and returning machine belongs to agricultural machinery; the machine includes a corn stalk introduction mechanism composed of a reel chain group and a stalk roller, a corn stalk composed of a moving knife, a fixed knife, a material conveying side plate, and a knife hub. Straw cutting and crushing mechanism, rubbing and crushing mechanism composed of toothed rubbing roller, toothed rubbing block, roller cover plate, rubbing gap adjustment bolt group, pressure spring, external power input shaft, driving pulley, driven The power transmission system composed of pulley, transmission belt, transfer shaft, gearbox, reversing transmission gearbox, cutter hub drive shaft, and cutter hub; through the combination of cutting and crushing of corn stalks and extrusion, cutting, tearing, kneading and crushing combined operations, the Improve the quality of corn stalk crushing and returning to the field, which is beneficial to the rot and degradation of corn stalks, and give full play to the advantages of corn stalk returning to the field. The structure of the machine is novel and reasonable, the operation quality is good, the efficiency is high, and the use is reliable.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

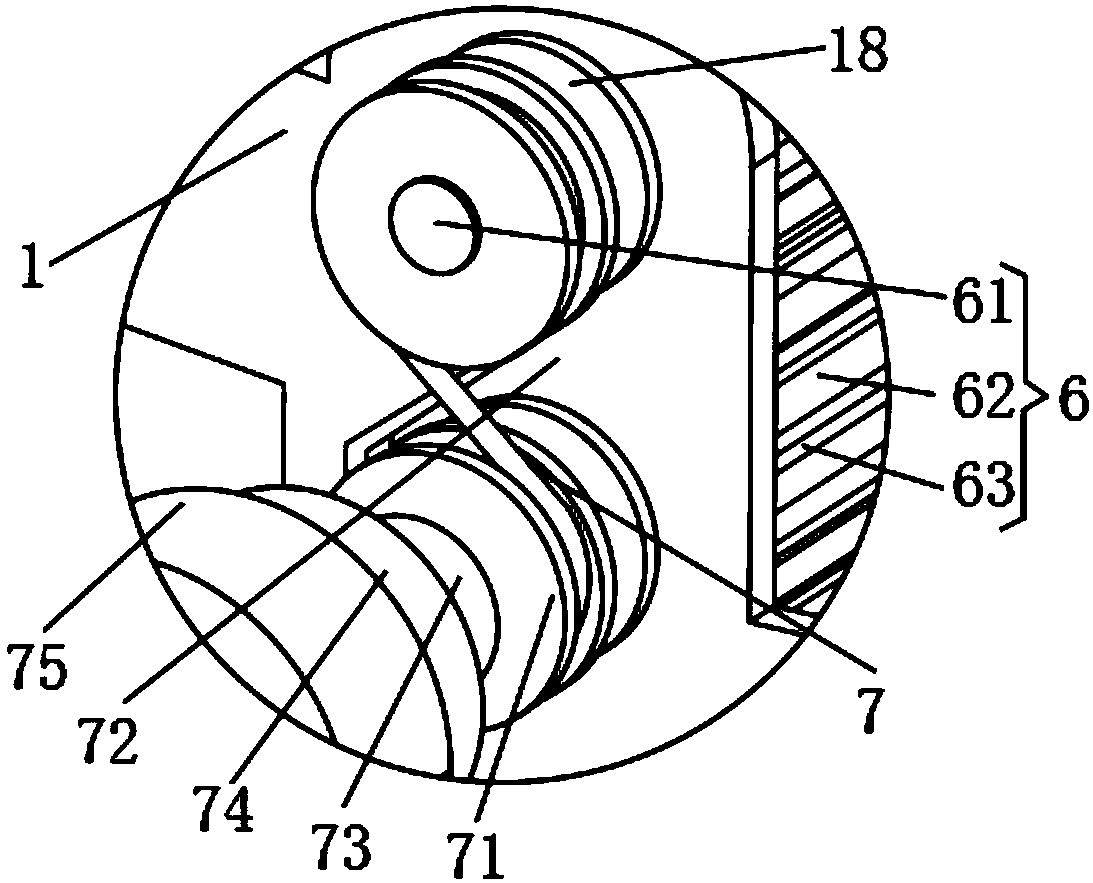

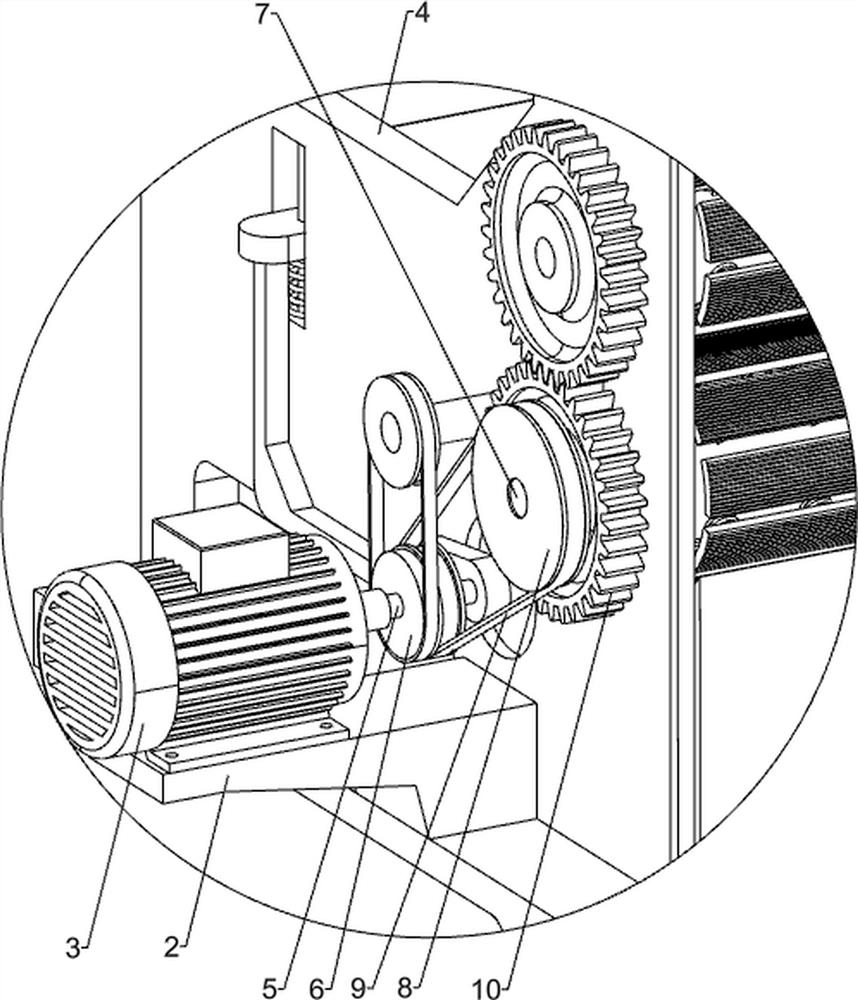

Loofah collateral taking and shell breaking process

ActiveCN113275078AMeet breaking requirementsConducive to decayGrain treatmentsMetal working apparatusElectric machineGear wheel

The invention relates to a loofah collateral taking process, in particular to a loofah collateral taking and shell breaking process. The invention provides a loofah collateral taking and shell breaking process, The loofah collateral taking and shell breaking process comprises a base, a mounting base, a motor, bin plates, a bin hopper, a first shaft rod, a multi-groove belt wheel, a second shaft rod, a large belt wheel, a first belt, a gear and the like, wherein the mounting base is fixedly connected to one side of the base, the motor is mounted on the mounting base, the first shaft rod is connected to an output shaft of the motor through a coupler, and a pair of bin plates is mounted on the base. Loofah is put into the bin hopper, passes through a buffer conveying roller to form a first shell breaking process, passes through a rotating circular blade to realize a second shell breaking process, passes through a bearing sliding plate and is close to the bearing sliding plate by using the pressing plate to realize a third shell breaking process, and three shell breaking processes of the loofah skin are performed to realize the shell breaking process, so that the surface of the loofah meets the shell breaking requirement, and the loofah is more convenient to soak to rot the loofah skin.

Owner:重庆何航鞋业有限公司

Machine-transplanted staple cotton seedling strengthening agent seedling raising body and preparation method thereof

PendingCN111567385ASolve problems such as difficulty in soil extraction and complex matrix compounding processThe method of raising seedlings is simpleSuperphosphatesGrowth substratesHorticultureBotany

The invention discloses a machine-transplanted staple cotton seedling strengthening agent seedling raising body and a preparation method thereof. The machine-transplanted staple cotton seedling strengthening agent seedling raising body comprises an upper staple cotton seedling raising body, a seedling strengthening agent and a lower staple cotton seedling raising body, wherein the seedling strengthening agent is uniformly spread on the upper surface of the lower staple cotton seedling raising body; the upper staple cotton seedling raising body and the lower staple cotton seedling raising bodyare connected into a whole; a crease is arranged at the joint of the upper staple cotton seedling raising body and the lower staple cotton seedling raising body; and the upper staple cotton seedling raising body is folded along the crease and covers the lower staple cotton seedling raising body. Materials of the seedling raising body are easy to obtain, the seedling raising method is simple, and the seedling raising efficiency is high.

Owner:武汉世纪金辉农业科技有限公司

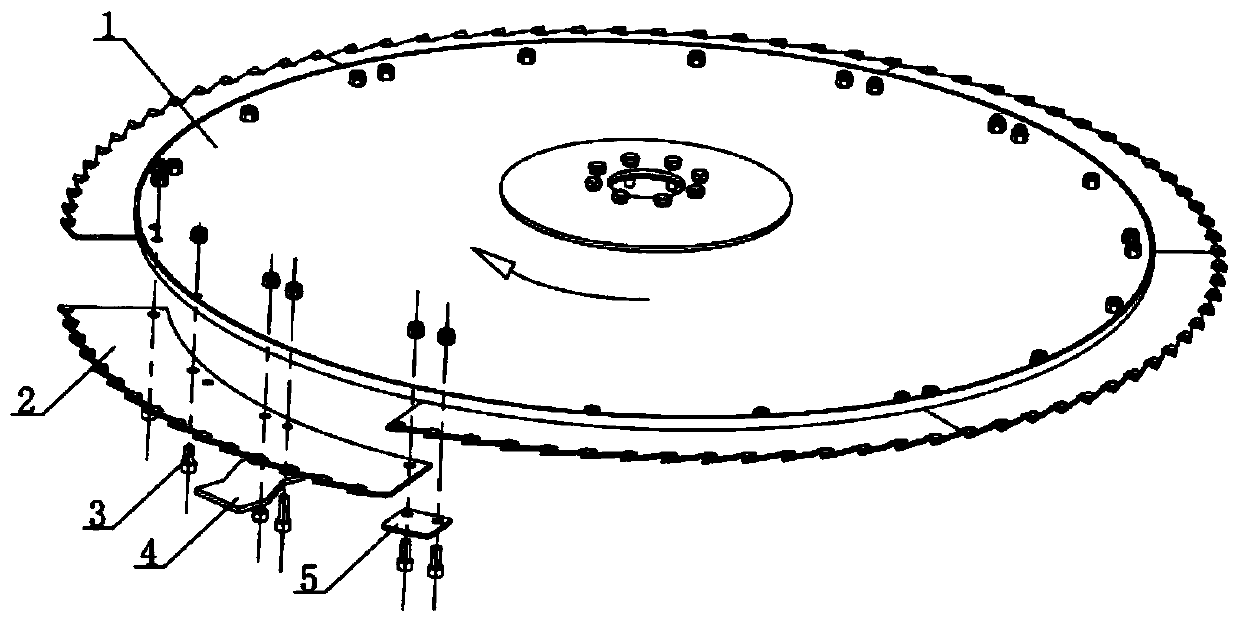

High-speed and high-efficiency paddy field harrow

The invention discloses a high-speed and high-efficiency paddy field harrow. Suspending boards are arranged on the two sides of a main machine frame. A power output box is arranged in the middle of the main machine frame. A transmission shaft I, a transmission shaft II and a transmission shaft III are installed on the power output box. A gear I and a driven bevel gear are arranged on the transmission shaft I. A gear II is arranged on the transmission shaft II. A gear III is installed on the transmission shaft III. One end of a power input shaft is provided with a spline coupler and the other end of the power input shaft is provided with a driving bevel gear meshed with the driven bevel gear. The gear II is meshed with the gear I and the gear III at the same time. The transmission shaft III serves as a power output shaft. The two ends of the transmission shaft III extend out of a box body and are respectively provided with a spline flange disc. The two spline flange discs are respectively connected with a driving harrow connector of a rolling harrow body. One end of a rolling harrow supporting shaft of each rolling harrow body is connected with the corresponding driving harrow connector and the other end of the rolling harrow supporting shaft of each rolling harrow body is installed on a bearing block through a bearing. The bearing blocks are fixed to the suspending boards. According to the high-speed and high-efficiency paddy field harrow, the cultivation efficiency is high, operation, maintenance and repair are convenient, and the requirements of various paddy field cultivation environments and the cultivation requirements of crops such as water chestnuts and sagittaria sagittifolia can be satisfied.

Owner:GUANGXI LANGUANG TECH

Automatic protecting harvesting machine

The invention discloses an automatic protecting harvesting machine which comprises a frame, wherein a cab and a harvesting device are arranged on the frame, and walking wheels are arranged at the lower end of the frame; the harvesting device comprises a harvesting opening; a harvesting cutter is arranged at the harvesting opening; a rotary drum is arranged at the lower end of the harvesting opening; a cutter is arranged on the rotary drum; a storage box is arranged on the frame; the harvesting opening is communicated with the storage box. According to the automatic protecting harvesting machine, the working efficiency can be improved.

Owner:新津县宝龙生态家庭农场

Rotary drum type cutter for micro combine

The present invention discloses a kind of rotary drum type cutter for micro combine, and relates to rice harvesting machinery. The rotary drum type cutter consists of static blades, dynamic blades, drum, left shaft, left fixing frame, left bearing seat, right shaft, sliding sleeve, right fixing frame, right bearing seat, and shift fork unit. The cutter can cut rice straw into short sections and press the straw sections into mud with less power consumption. The micro combine with the cutter may be used in both hilly area and flat land to harvest rice.

Owner:GAOKE INNOVATION TECH INST QIYANG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com