Standing type machine for smashing and rubbing corn stalks and returning corn stalks to field

A corn stalk and rack technology, which is applied to the field of corn stalk returning machines and tools, can solve the problems of reduced seed germination rate, difficulty in exerting advantages, long time, etc., and achieves the effects of improving the returning quality, good operation quality and novel structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

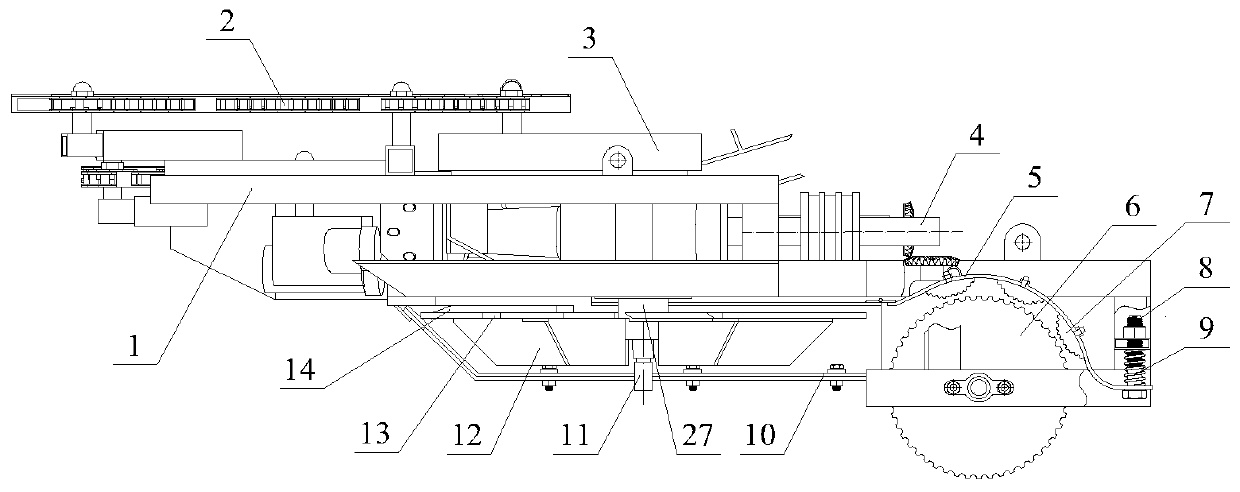

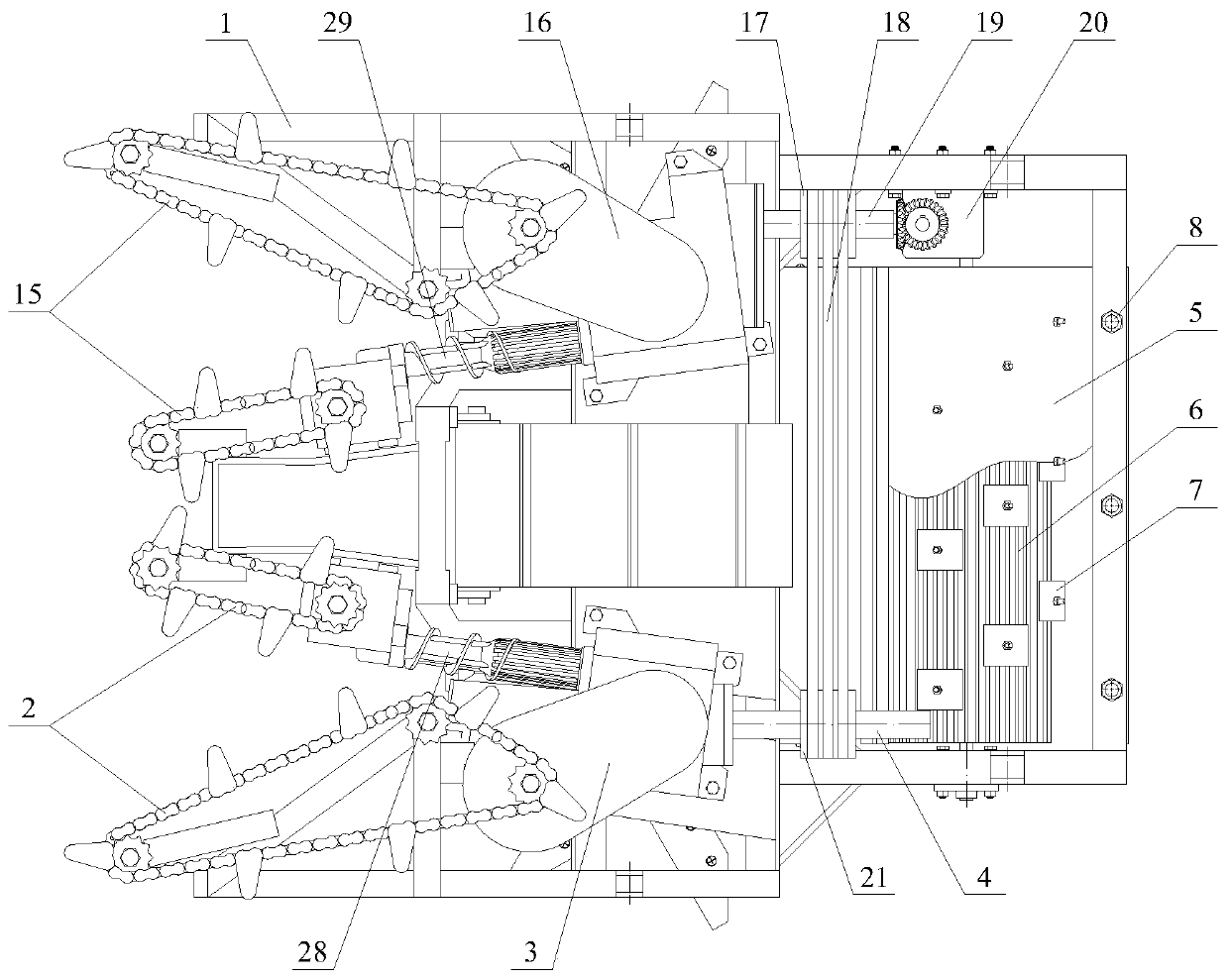

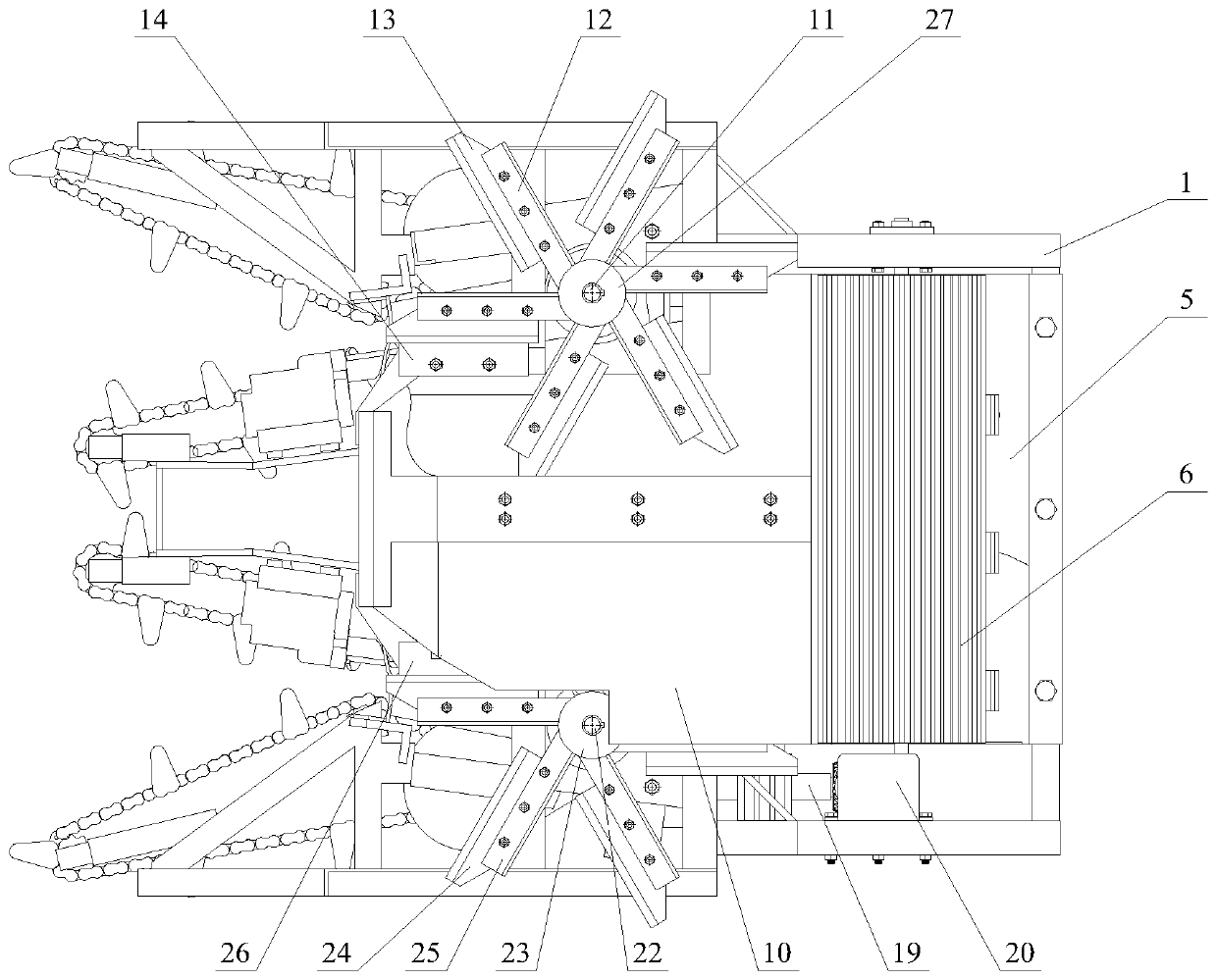

[0011] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A stand-up corn stalk crushing, kneading and returning machine includes a frame 1, on the left and right sides of the front end of the frame 1, a left rattle chain group 2, a left stem roller 28 and a right The reel chain group 15 and the right stem roller 29 are installed on the upper left side of the frame 1, and the left gear box 3 is installed at the rear side of the left reel chain group 2 and the left stem roller 28, and the left gear The box 3 is respectively connected with the left reel chain group 2 and the left stem roller 28, on the upper right side of the frame 1, at the rear side of the right reel chain group 15 and the right stem roller 29 from front to back Equipped with a right gear box 16 and a reversing transmission gear box 20, the right gear box 16 is connected with the right rattle chain group 15 and the right stem roller 29 respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com