Canopy regulation and control method for improving mechanical kernel harvesting quality and kernel commodity quality of corns

A technology of commodity quality and planting method, applied in the fields of botanical equipment and methods, horticultural methods, horticulture, etc., can solve the problems of missing key time points of technical operations, increased risk of mildew and lodging, and weakened ventilation and light transmission of groups, etc. Achieve the effect of promoting the reduction of lodging fold rate and grain moisture content, improving the quality of straw returning to the field, and improving quality and efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

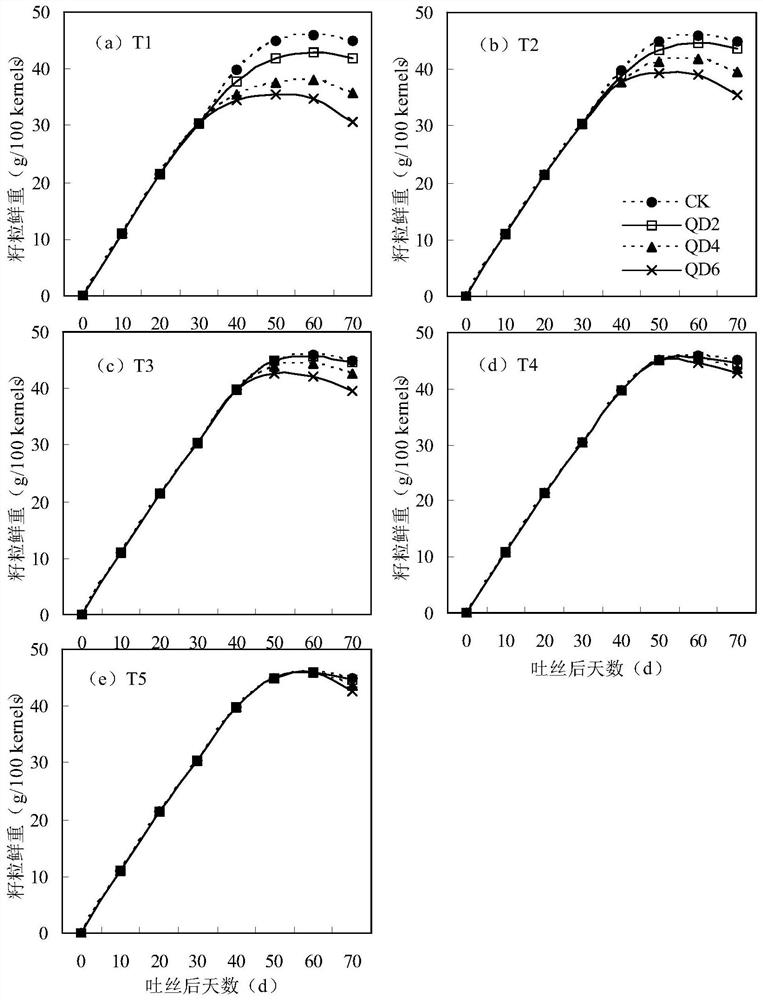

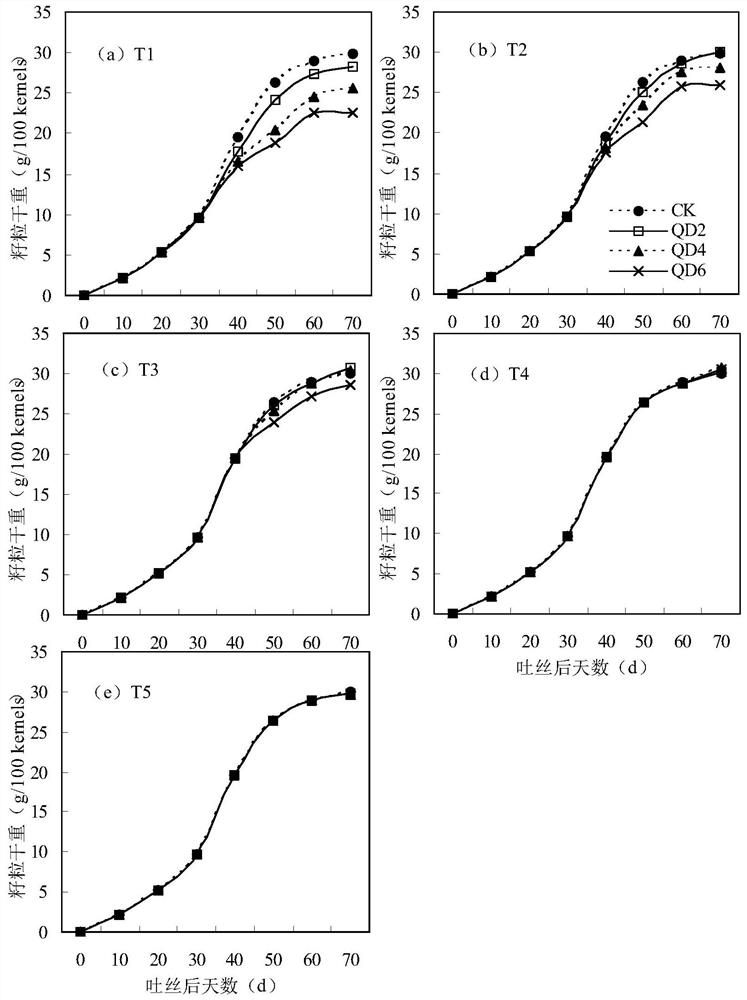

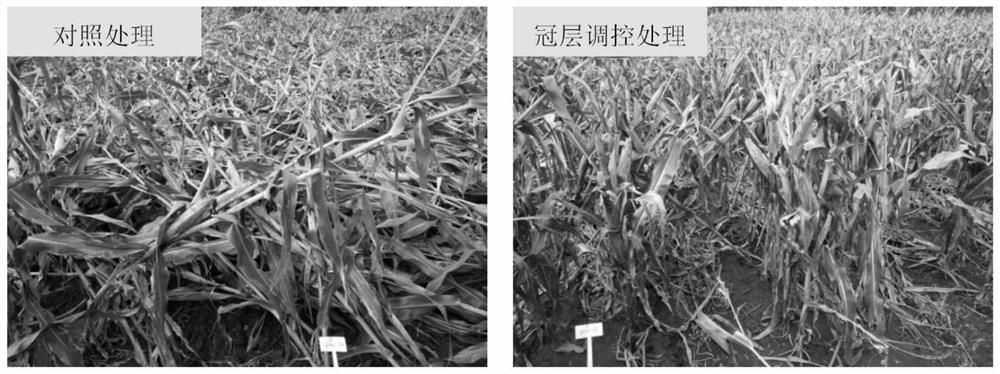

[0044]Example 1. Effects of different canopy control treatment combinations on corn grain filling, dehydration characteristics, yield and mechanical grain harvest quality

[0045]1. Test materials and methods

[0046]1. Test time and place

[0047]The experiment was carried out in the experimental practice base of Heilongjiang Bayi Agricultural University (46°37′N, 125°11′E) in 2018. The soil type is alkalized meadow soil. Before sowing, the organic matter content of 0-20cm soil layer was 10.71g / kg, the alkali hydrolyzed nitrogen was 117.27mg / kg, the available phosphorus was 3.69mg / kg, the available potassium was 94.59mg / kg, and the pH was 8.3.

[0048]2. Test materials

[0049]Xianyu 335, a corn variety with regional typicality and representativeness, was selected as the test material.

[0050]3. Experimental design

[0051]Finely prepare the ground before sowing, sowing on May 5, 2017, planting density 75,000 plants / hm2, Harvested on October 5, 2017. The experiment adopts a split zone design. The main...

Embodiment 2

[0121]Example 2. The effect of different canopy control measures on the mechanical grain harvest quality of Demeiya No. 3 corn and the quality of related commodities

[0122]1. Test materials and methods

[0123]1. Test time and place

[0124]The experiment was carried out in the 850 Farm in Heilongjiang Province in 2019.

[0125]2. Test materials

[0126]The corn variety Demeiya No. 3 with regional typicality and representativeness was selected as the test material.

[0127]3. Experimental design

[0128]Planting density is 82,500 plants / hm2.

[0129]Four treatment groups were set up in the experiment: T31QD2 was cutting 2 stalks at 31d after spinning, T38QD4 was cutting 4 stalks at 38d after spinning, T45QD5 was cutting 5 stalks at 45d after spinning, and T52QD6 was spinning Cut 6 stalks after 52 days. At the same time, no canopy regulation was used as the control group (CK).

[0130]2. Test results

[0131]It can be seen from Table 8 that compared with CK and T52QD6 treatments, the incidence of lodging in Dem...

Embodiment 3

[0134]Example 3. The effect of different canopy control measures on the quality of mechanical grain harvest of Zhengdan 958 corn and the quality of related commodities in Zhaozhou County

[0135]1. Test materials and methods

[0136]1. Test time and place

[0137]The trial was conducted in Zhaozhou County, Daqing City, Heilongjiang Province in 2019.

[0138]2. Test materials

[0139]Zhengdan 958, a corn variety with regional typicality and representativeness, was selected as the test material.

[0140]3. Experimental design

[0141]Planting density is 67,500 plants / hm2.

[0142]Four treatment groups were set up in the experiment: T35QD2 was cutting 2 stalks at 35d after spinning, T41QD4 was cutting 4 stalks at 41d after spinning, T49QD6 was cutting 6 stalks at 49d after spinning, and T55QD6 was spinning Cut 6 stalks after 55 days. At the same time, no canopy regulation was used as the control group (CK).

[0143]2. Test results

[0144]It can be seen from Table 9 that compared with CK and T52QD6 treatments, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com