Loofah collateral taking and shell breaking process

A technology of loofah and process, applied in the field of loofah extracting and breaking the shell, can solve the problems of waste of manpower, low efficiency of loofah skin, unsuitable batch work, etc., and achieve the effect of facilitating the rot of melon skin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

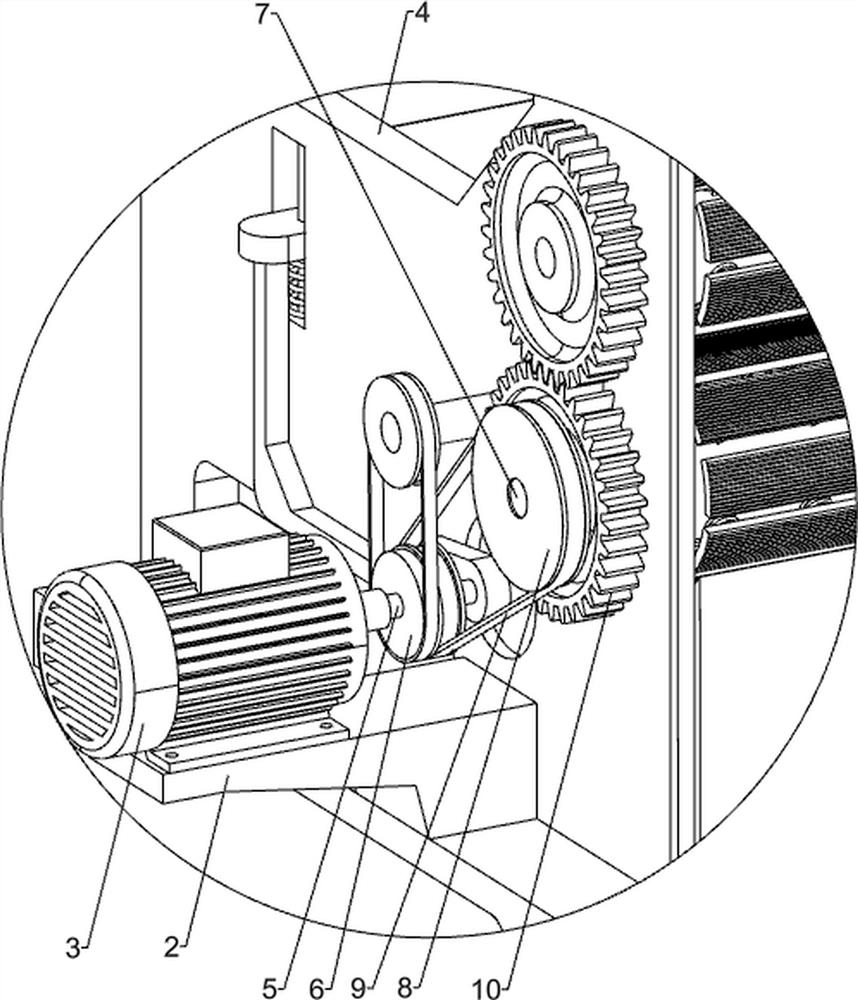

[0022] A kind of sponge gourd gets the network broken shell technology, such as figure 1 and figure 2 As shown, it includes a base 1, a mounting seat 2, a motor 3, a bin plate 4, a bin 401, a first shaft 5, a multi-groove pulley 6, a second shaft 7, a large pulley 8, and a first belt 9 , gear 10, buffer transfer roller 11 and a mechanism for cutting the loofah skin, one side of the base 1 is fixedly connected with a mounting seat 2, a motor 3 is installed on the mounting seat 2, and the output shaft of the motor 3 is connected with the first shaft through a coupling Rod 5, a pair of warehouse plates 4 are installed on the base 1, the first shaft rod 5 is rotationally connected with the warehouse boards 4 on both sides, the bins 401 are connected to the warehouse boards 4 on both sides, and the first shaft rod 5 is connected with a multi-slot belt Wheel 6, a pair of second shaft rods 7 are connected with rotation on the two sides of the warehouse plate 4, and one of the secon...

Embodiment 2

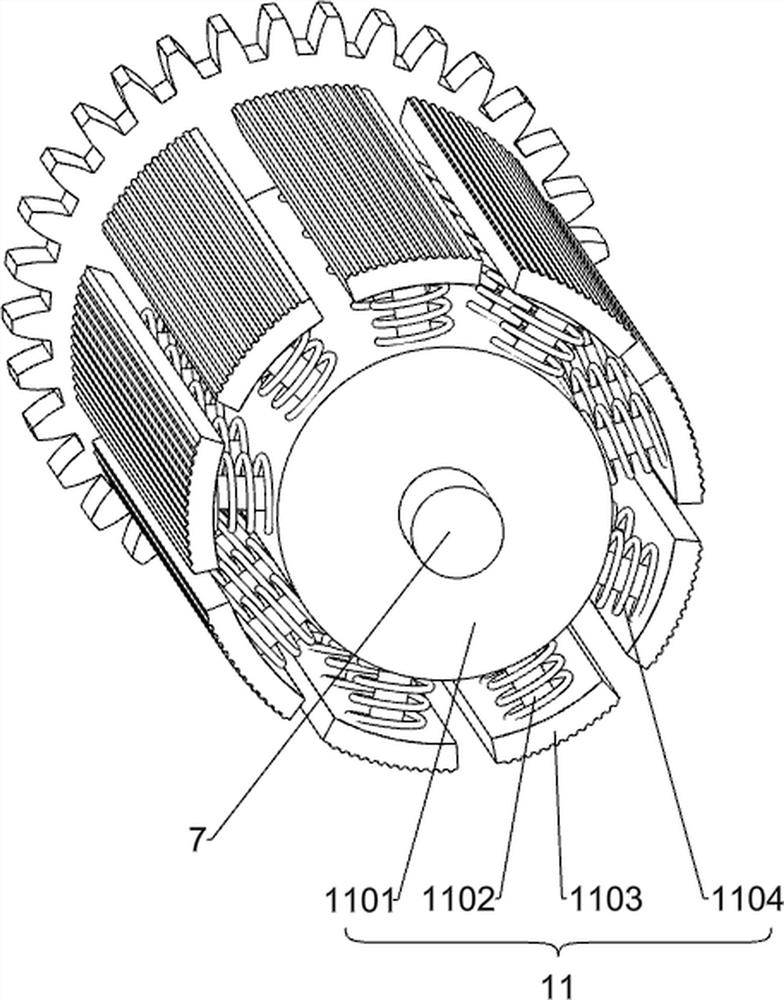

[0025] On the basis of Example 1, such as image 3 As shown, the buffer transfer roller 11 includes a roller 1101, a slide bar 1102, an arc-shaped friction plate 1103 and a first spring 1104, the second shaft 7 is fixedly connected with the roller 1101, and the roller 1101 is slidably connected with a plurality of Slide bar 1102, the top of each row of slide bar 1102 is fixedly connected with an arc-shaped friction plate 1103, each slide bar 1102 is covered with a first spring 1104, one end of the first spring 1104 is connected with the roller 1101, the first The other end of the spring 1104 is connected to the arc-shaped friction plate 1103 , and the arc-shaped friction plate 1103 can slide towards the center of the roller 1101 through the slide bar 1102 .

[0026] When the loofah passes through the buffering and conveying rollers 11 on both sides, the arc-shaped friction plates 1103 clamping the loofah on both sides press the sliding rod 1102 to move toward the roller 1101. ...

Embodiment 3

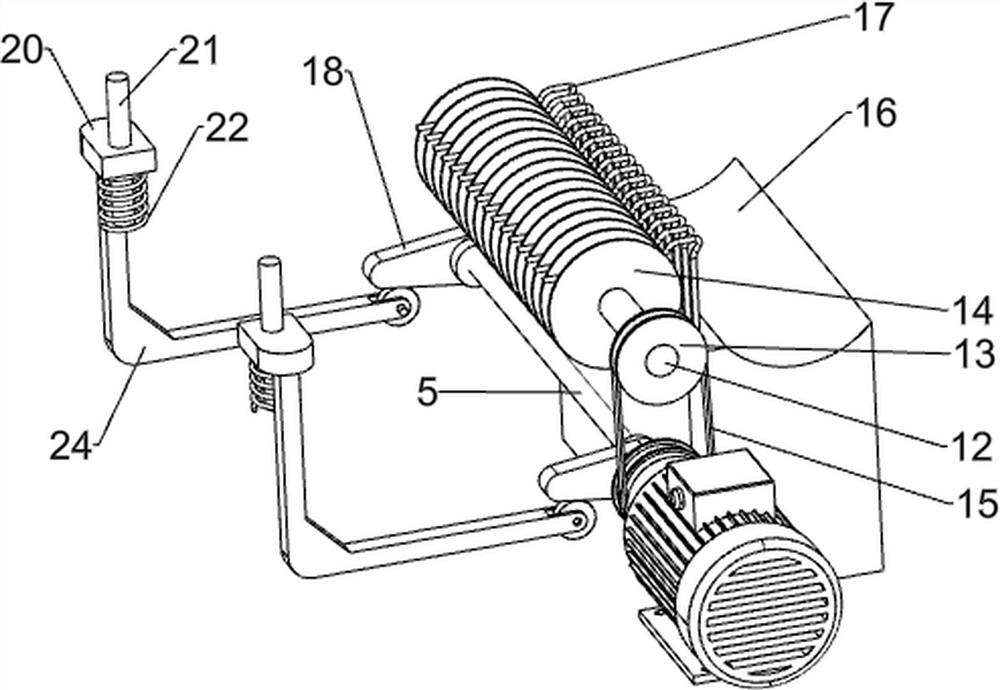

[0028] On the basis of Example 2, such as Figure 4 As shown, the cutting loofah skin mechanism includes a third shaft 12, a small pulley 13, a circular blade 14 and a second belt 15, and the two sides of the warehouse plate 4 are rotatably connected with a third shaft 12, and the third shaft 12 A small pulley 13 is fixedly connected to the side close to the multi-groove pulley 6, a second belt 15 is wound around the small pulley 13 and the multi-groove pulley 6, and a plurality of round blades are fixedly connected to the third shaft 12 at even intervals. 14, the round blade 14 is close to the buffer transfer roller 11 below.

[0029] When the motor 3 rotates, the multi-groove pulley 6 on it drives the small pulley 13 to rotate by the second belt 15, and the small pulley 13 rotates to drive the third shaft rod 12 to rotate, and the third shaft rod 12 drives the circular blade 14 to rotate. The loofah that has been conveyed in the side buffer transfer drum 11 passes through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com