High-speed and high-efficiency paddy field harrow

A high-speed, high-efficiency technology, applied in the field of agricultural machinery, can solve the problems of paddy field raking, etc., and achieve the effect of benefiting rot, enhancing crushing function, rigidity and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

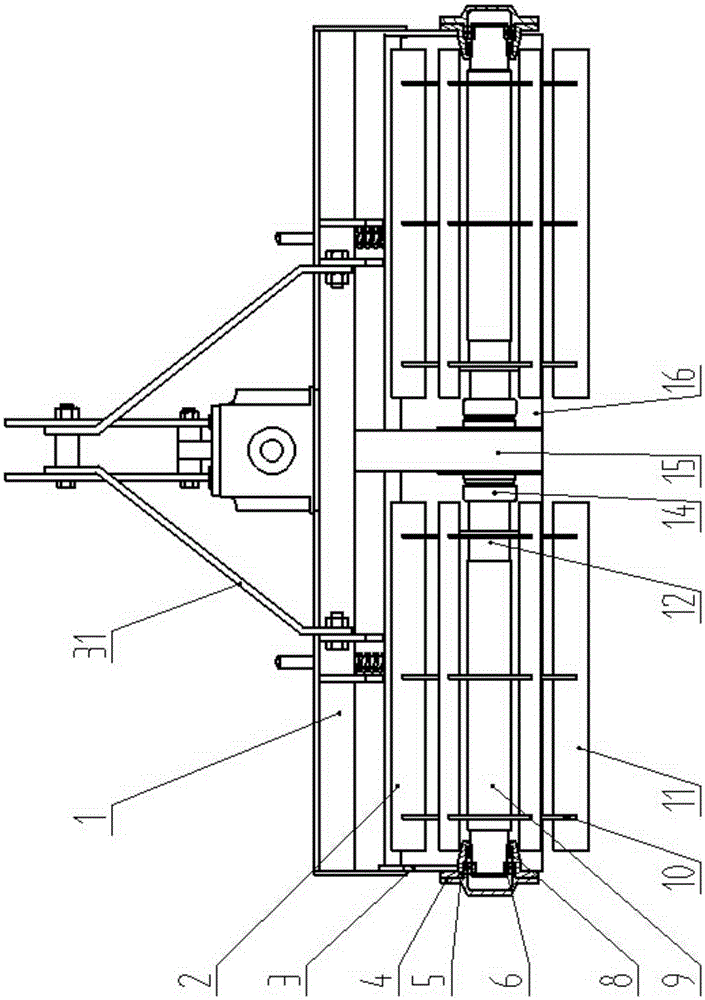

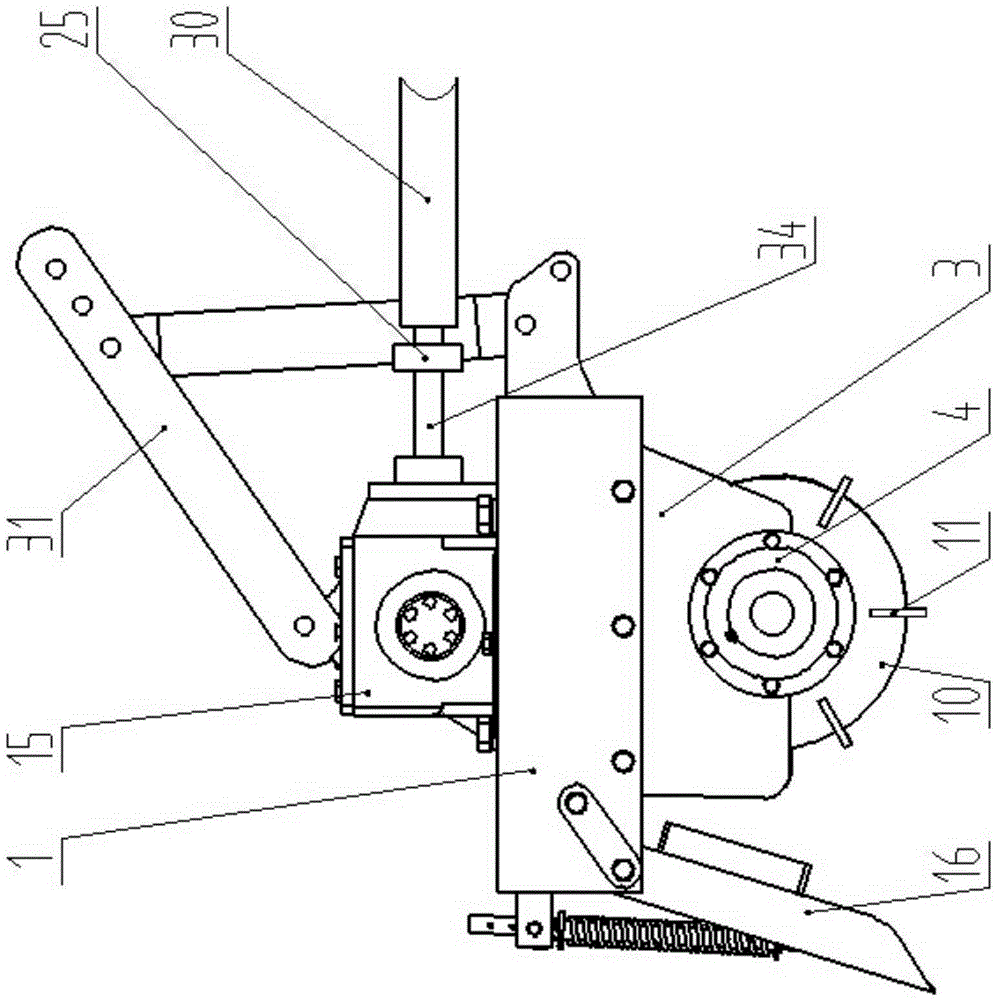

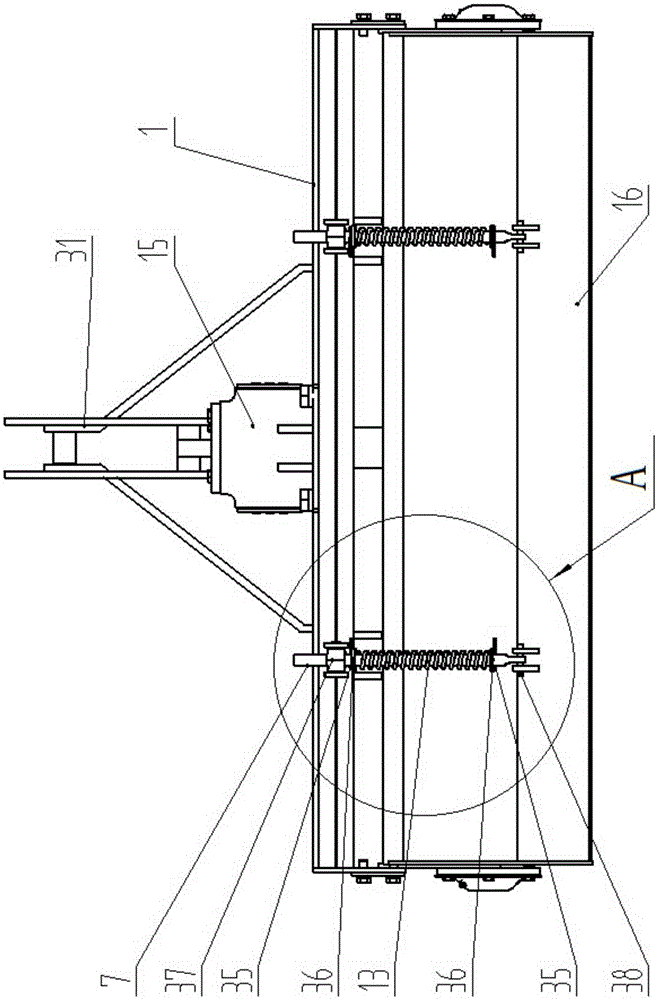

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

[0025] Such as figure 1 , figure 2 , image 3 As shown, the paddy field harrow of the present invention is mainly composed of a main frame 1, two rolling rakes 2 and a power transmission box 15, the two sides of the main frame 1 are respectively connected with suspension plates 3, the middle part of the main frame 1 is connected with the power transmission box 15, and three points The suspension support frame 31 is installed on the main frame 1 and the power transmission box 15, and the paddy field rake is connected with the tractor I class standard three-point suspension through the three-point suspension support frame 31. In the power transmission box 15, the bearing IV 29, the bearing I28, The bearing II24 is equipped with three transmission shafts I17, II20 and III23 arranged in parallel, the gear I19 and the driven bevel gear 18 are installed on the transmissio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com