New rolling harrow

A rolling rake and rolling technology, applied in the field of agricultural tools, can solve problems such as poor ground flatness, damage to the top of the support block, violent rolling, etc., and achieve the effects of good flatness, increased strength, and increased weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

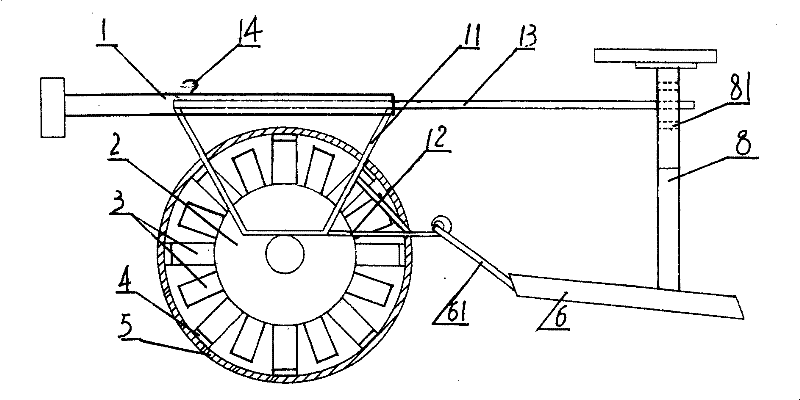

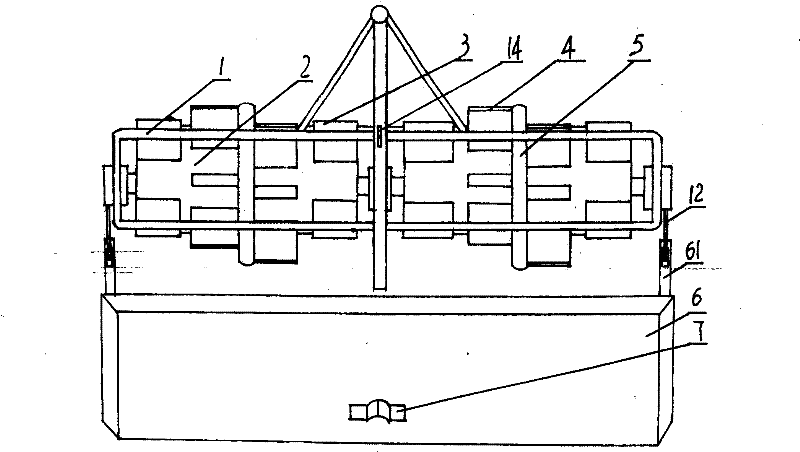

[0012] Such as figure 1 As shown, the new rolling rake includes a rectangular rake frame 1 and two cylindrical rollers 2 installed side by side under the rectangular rake frame. The cushion support bar 8 that pole connects. The tops of the adjacent two circles of lamellar teeth in the middle of the rolling cylinder are welded with channel irons 4 respectively, and a hoop 5 is welded between one side of the adjacent two circles of the channel irons. The rear of the rectangular rake frame is provided with dragging plate 6. That is: a connecting rod 12 with a hook on the rear end is respectively fixed on the brackets 11 below both sides of the rake frame, and a connecting rod 61 with a hook groove at the end is respectively connected to the two sides of the front side of the carriage. The hook groove on the top is matched with the hook on the end of the connecting rod to facilitate the loading and unloading of the pallet.

[0013] The axial length of the channel iron 4 is the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com