Miniature asymmetric surface mounted fuse and manufacturing method thereof

A surface mount and manufacturing method technology, applied in fuse manufacturing, emergency protection devices, electrical components, etc., can solve problems such as easy to be broken, fuse layer burst, poor breaking ability, etc., to achieve simple process and processing methods, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

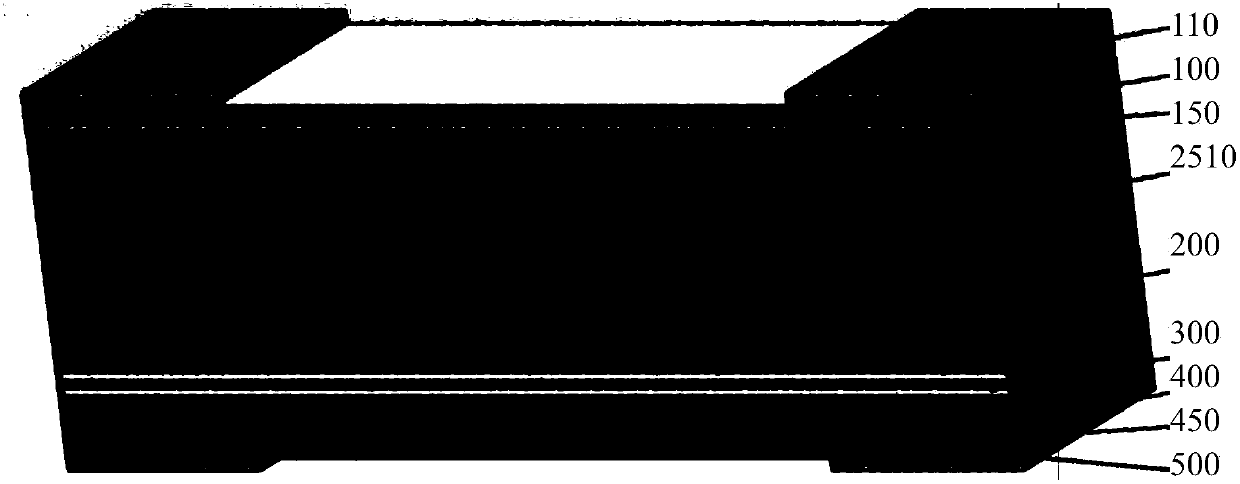

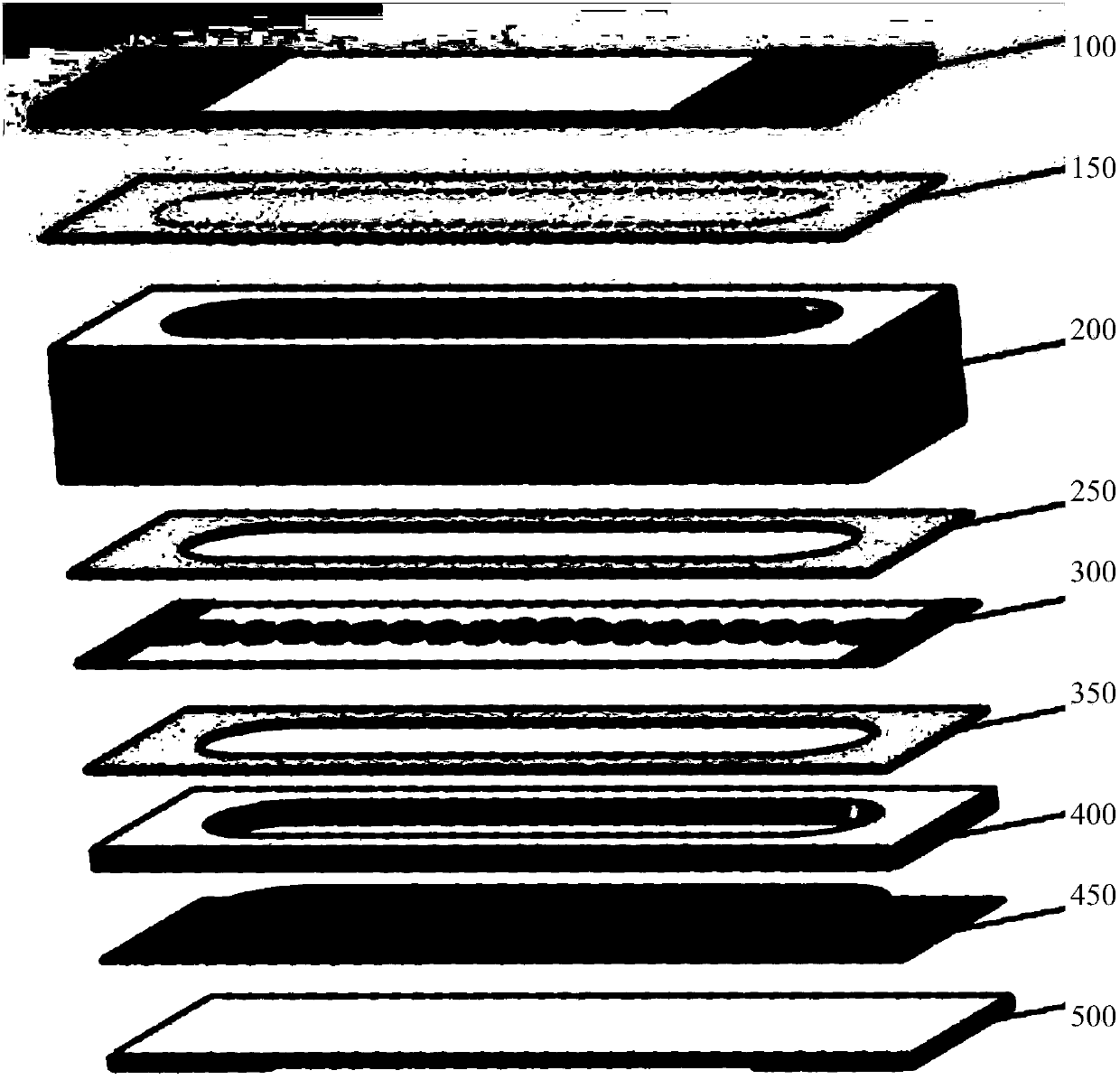

[0050] Such as Figure 1-3 As shown, Embodiment 1 of the present invention provides a miniature asymmetric surface mount fuse, which includes an upper substrate 100 pressed together from top to bottom, a first cavity plate 200 with a first cavity, and a top surface The melt plate 300 with the melt bonded, the second cavity plate 400 with the second cavity and the lower substrate 500, wherein the second cavity plate 400 and the lower substrate 500 are bonded by the lower elastic adhesive layer 450 , and the second cavity is filled by the lower elastic adhesive layer 450, the volume fraction of the lower elastic adhesive layer 450 filled in the second cavity is between 50-120%, and the second cavity in this embodiment is filled by The lower elastic adhesive layer 450 is just filled; the remaining parts of the surface mount fuse are bonded by pure adhesive film. The pure rubber film includes an upper glue layer 150, a middle upper glue layer 250 and a middle lower glue layer 350...

Embodiment 2

[0063] Such as Figure 4 As shown, another embodiment of the present invention is a miniature asymmetric surface mount fuse, which includes an upper substrate 100 pressed together from top to bottom, a first cavity plate 200 with a first cavity, a top The melt plate 300 with the melt on the surface, the second cavity plate 400 with the second cavity and the lower substrate 500, wherein the second cavity plate 400 and the lower substrate 500 are bonded by the lower elastic adhesive layer 450 close, and the second cavity is filled by the lower elastic adhesive layer 450, the volume fraction of the lower elastic adhesive layer 450 filled in the second cavity is between 50-100%, the second cavity in this embodiment It is just filled by the lower elastic adhesive layer 450; the first cavity plate 200, the melt plate 300 and the second cavity plate 400 of the surface mount fuse are bonded by a pure adhesive film. The pure rubber film includes an upper glue layer 150, a middle upper...

Embodiment 3

[0076] Such as Figure 5 As shown, another embodiment of the present invention is a miniature asymmetric surface mount fuse, which includes an upper substrate 100 pressed together from top to bottom, a first cavity plate 200 with a first cavity, a top The melt plate 300 with the melt on the surface, the second cavity plate 400 with the second cavity and the lower substrate 500, wherein the upper substrate 100 and the first cavity plate 200 are bonded by the upper elastic adhesive layer 451 Close, the second cavity plate 400 and the lower substrate 500 are bonded by the lower elastic adhesive layer 450, and the second cavity is filled by the lower elastic adhesive layer 450; the first cavity plate 200 of the surface mount fuse, the fuse The body board 300 and the second cavity board 400 are bonded by a pure glue film. The upper elastic adhesive layer 451 and the lower elastic adhesive layer 450 are composed of multiple layers of adhesive.

[0077] The surfaces of the upper su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com