Peanut fruit-harvesting and straw-returning integrated machine

An all-in-one machine and straw technology, which is applied to harvesters, excavator harvesters, crop processors, etc., can solve the problems of only harvesting peanut fruits and peanut leaves that cannot be handled well, and achieves benefits of subsequent growth and simple structure. , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

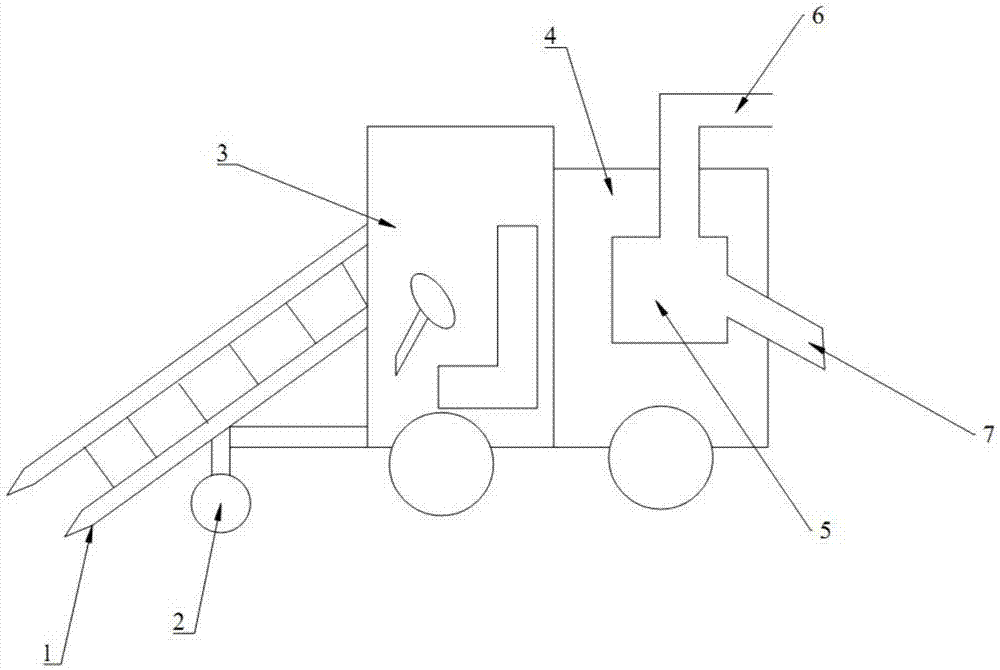

[0015] like figure 1 Shown: an integrated machine for peanut harvesting and straw returning to the field, its structure includes: loose soil conveying device 1, support wheel 2, cockpit 3, fruit harvesting device 4, rhizome grinder 5, air outlet 6, and material outlet 7 The soil loosening conveying device 1 is connected by a transmission belt in the middle of two vertical rods, the bottom ends of the two vertical rods of the loose soil conveying device 1 are shovel-shaped, and the upper end of the loose soil conveying device 1 is connected to the fruit receiving device 4 through a hinge. One end is connected, and the lower end surface of the loose soil conveying device 1 is equipped with a support wheel 2, and the support wheel 2 is connected with the cockpit 3 through a connecting rod. The cockpit 3 is a square structure, and the fruit harvesting device 4 is equipped with There is a rhizome grinder 5, and an air outlet 6 is installed on the upper end of the rhizome grinder 5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com