Oil solution for spandex spinning by dry method, and preparation and use thereof

A spandex spinning and oiling technology, which is applied in textiles and papermaking, fiber treatment, fiber types, etc., can solve the problems of large differences in unwinding force of silk cakes, blockage of oiling agent pipelines, and large unwinding tension of silk, etc., to achieve unwinding Uniform winding tension, avoiding adhesion, and not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

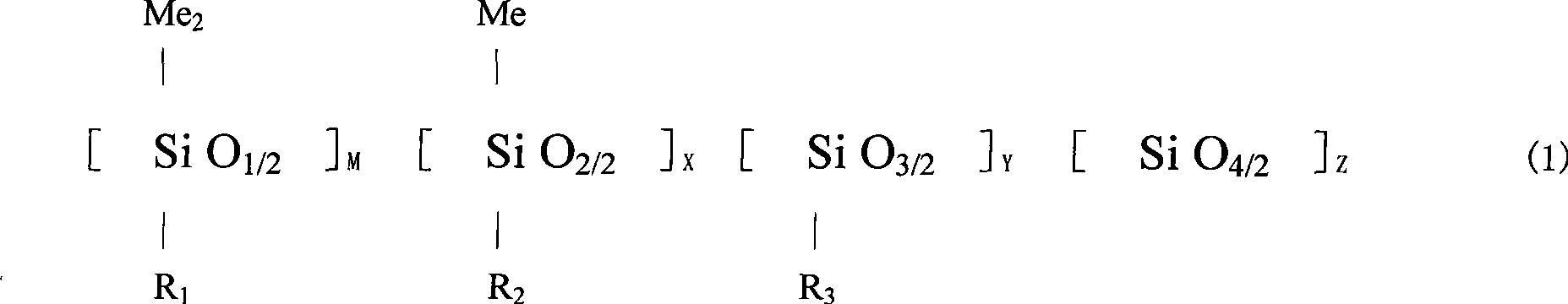

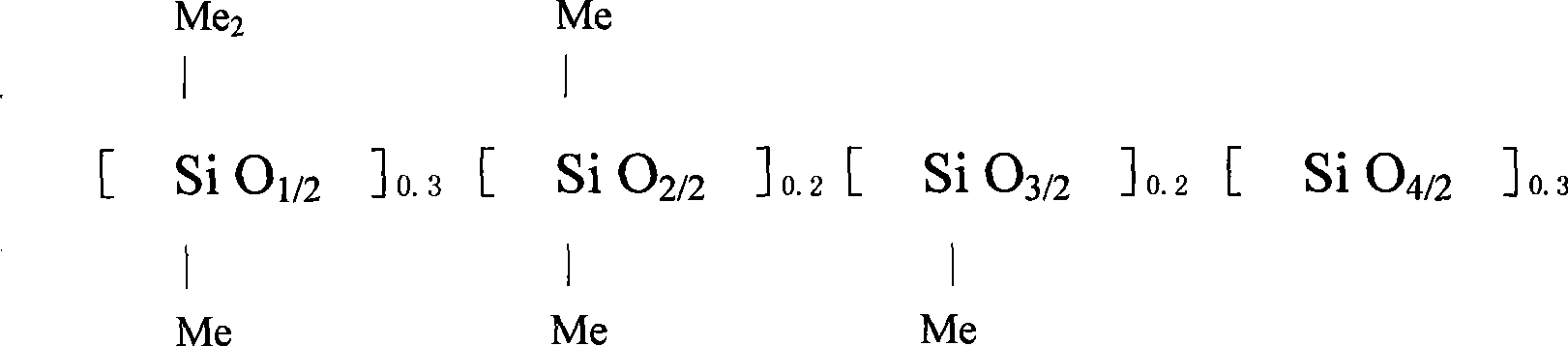

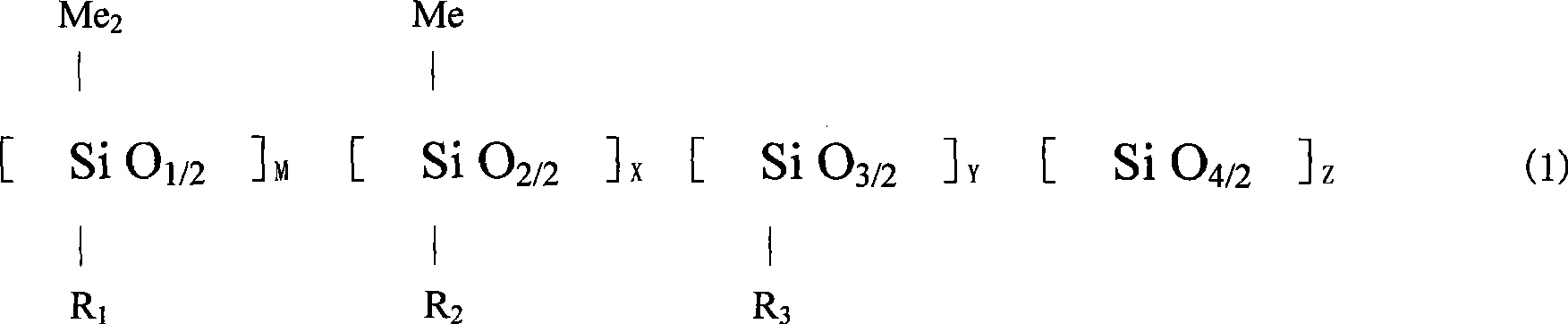

[0036] In a 500ml three-port glass reactor, add 32.4g hexamethyldisiloxane, 29.6g dimethyldiethoxysilane, 35.6g methyltriethoxysilane, 250g ethyl orthosilicate in sequence, stir and mix Evenly, at 25°C, start to add acidic water consisting of 50g of water and 10g of 30% hydrochloric acid dropwise, and finish adding within 1 hour. The temperature of the reaction solution rises to 70°C, and the color of the reaction solution gradually turns from colorless and transparent to milky white. After maintaining the reaction at a temperature of 60° C. to 70° C. for 1 hour, the stirring was stopped, and the reaction liquid was separated into two layers. The lower resin was separated, and the resin was washed with pure water until the pH was neutral. Refill the water-containing resin into the glass reactor, heat up and dehydrate under vacuum conditions, the dehydration temperature is 100°C-130°C, and the time is 2-3 hours, until the resin is colorless and transparent and reaches the requi...

Embodiment 2

[0041]In a 500ml three-port glass reactor, add 48.6g of hexamethyldisiloxane, 48g of dimethyldimethoxysilane, 54.4g of methyltrimethoxysilane, and 125g of ethyl orthosilicate in sequence, and stir and mix evenly. At 25°C, the acidic water consisting of 45g of water and 9g of 30% hydrochloric acid was added dropwise, and the addition was completed within 1 hour. The temperature of the reaction solution rose to 65°C, and the color of the reaction solution gradually changed from colorless and transparent to milky white. After maintaining the reaction at a temperature of 60° C. to 70° C. for 1 hour, the stirring was stopped, and the reaction liquid was separated into two layers. The lower resin was separated, and the resin was washed with pure water until the pH was neutral. Refill the water-containing resin into the glass reactor, heat up and dehydrate under vacuum conditions, the dehydration temperature is 100°C-130°C, and the time is 2-3 hours, until the resin is colorless and ...

Embodiment 3

[0046] The composition and the percentage composition of each component of dry-process spandex spinning oil agent in the present embodiment:

[0047] Silicone resin (structural formula 2) 10%

[0048] Methicone 40%

[0049] Polyether modified silicone oil 5%

[0050] Mineral Oil 43%

[0051] Antistatic agent 2%

[0052] Put the above components into the stirring tank one by one, and mix well and evenly at 20-40°C to obtain the colorless and transparent oil agent for dry-process spandex spinning of the present invention.

[0053] The main performance of the oil agent:

[0054] Appearance: colorless and transparent.

[0055] Viscosity: 10mPa.s.

[0056] PH value: 6~7

[0057] Volatile matter: 0.5% (100°C, 1hr)

[0058] The application result of oil agent in semi-continuous polymerization, dry spinning process is shown in table 1 below:

[0059] Table 1

[0060]

[0061] In this embodiment, adding 10% of the silicone resin compound represented by molecular formula (2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com