Mechanical type three-dimensional compact spinning device

A mechanical and compact technology, applied in the direction of spinning machines, textiles and papermaking, drafting equipment, etc., can solve the problems of yarn blocking, high production cost, and yarn quality in the twisting triangle area cannot be eliminated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

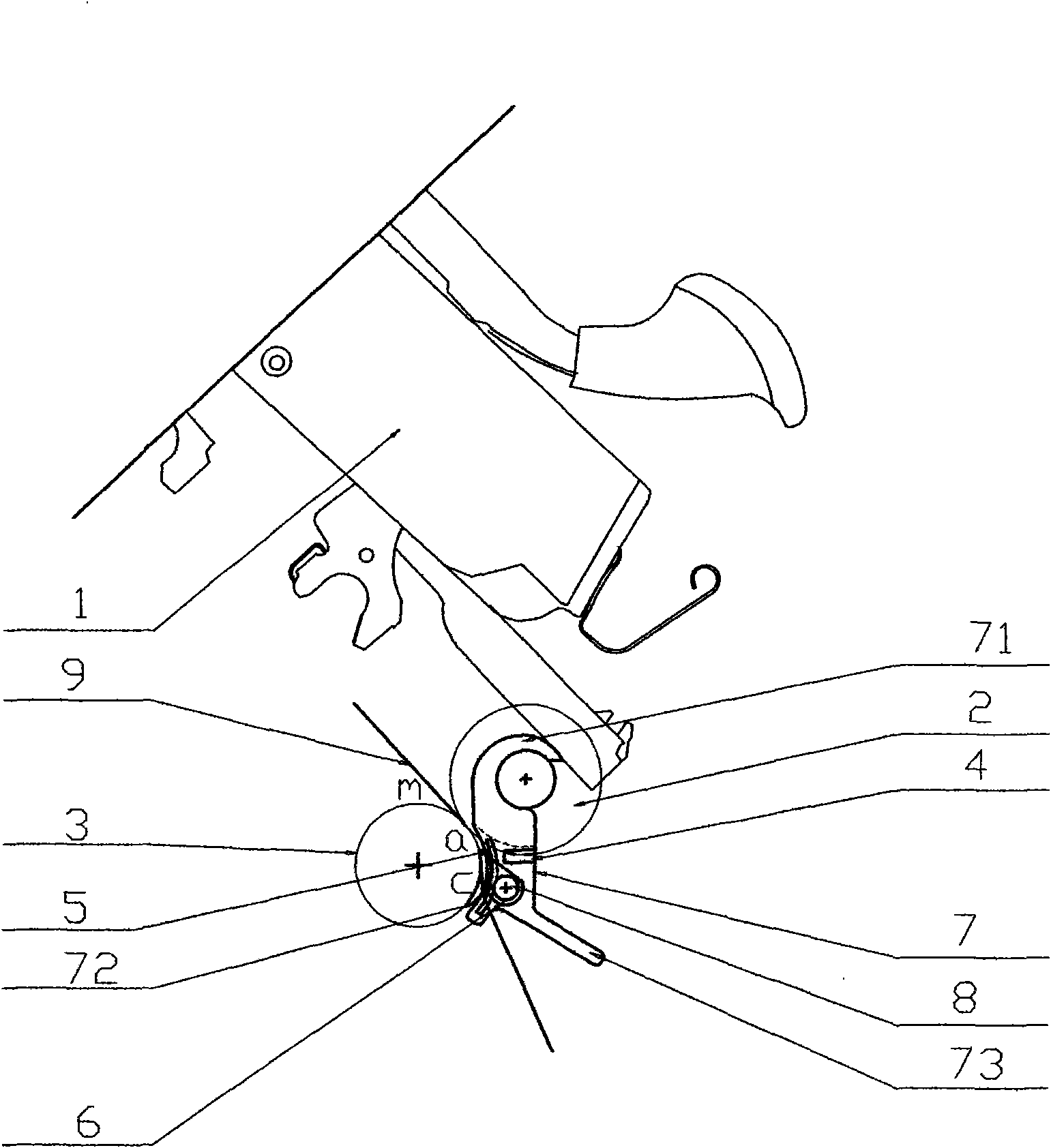

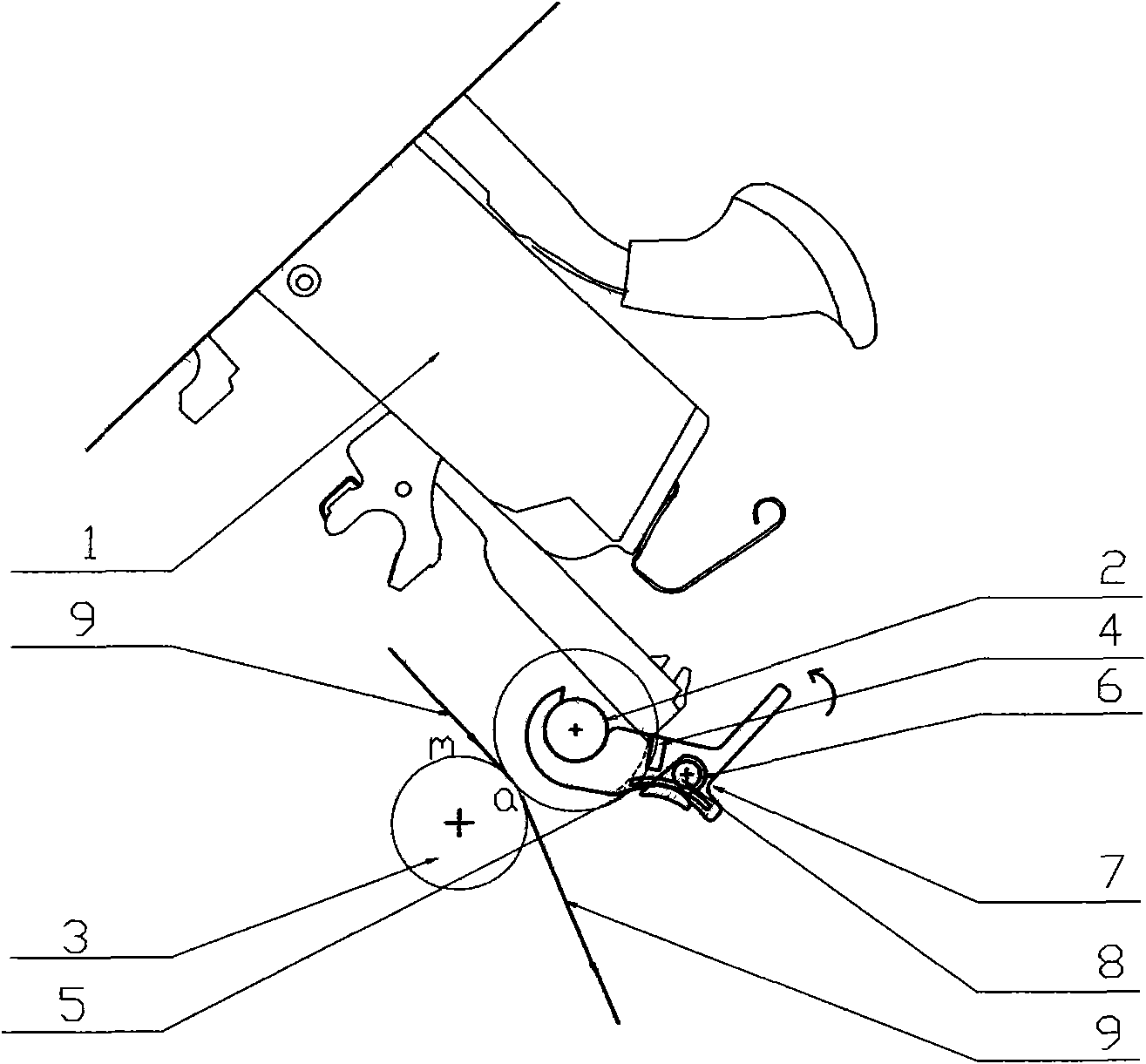

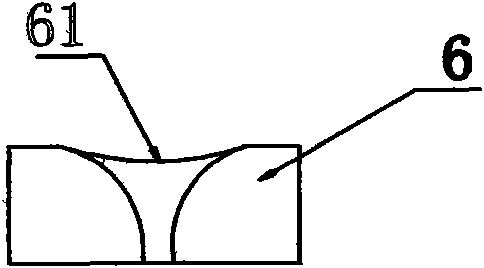

[0013] Such as figure 1 , figure 2 As shown, the bottom top roller 2 is installed on the cradle 1 of the spinning frame, and the bottom roller 3 is installed under the cradle 1 and pressed tightly on the bottom top roller 2. The gap formed between the bottom roller 3 and the bottom top roller 2 The contact area a forms the drafting area m between the pre-drafting device and the output end a of the drafting press roller composed of the bottom roller 3 and the bottom top roller 2 . Cage 7 has a movable end 71, arc recess 72 and handle 73, wherein, cage 7 is installed on the lower top roller 2 by movable end 71, and can rotate a certain angle around lower top roller 2, the arc of cage 7 The concave part 72 faces the side of the bottom roller 3, so as to fit the outer surface of the bottom roller 3. The handle 73 is used to operate the cage 7, so as to conveniently switch between the two working states of compact spinning and ordinary ring spinning. Two sets of magnets are inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com