Elastic disc type compact spinning apparatus

An elastic disc, compact spinning technology, applied in spinning machines, textiles and papermaking, drafting equipment, etc., can solve problems such as complex structure, inability to eliminate yarn quality, yarn jamming, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

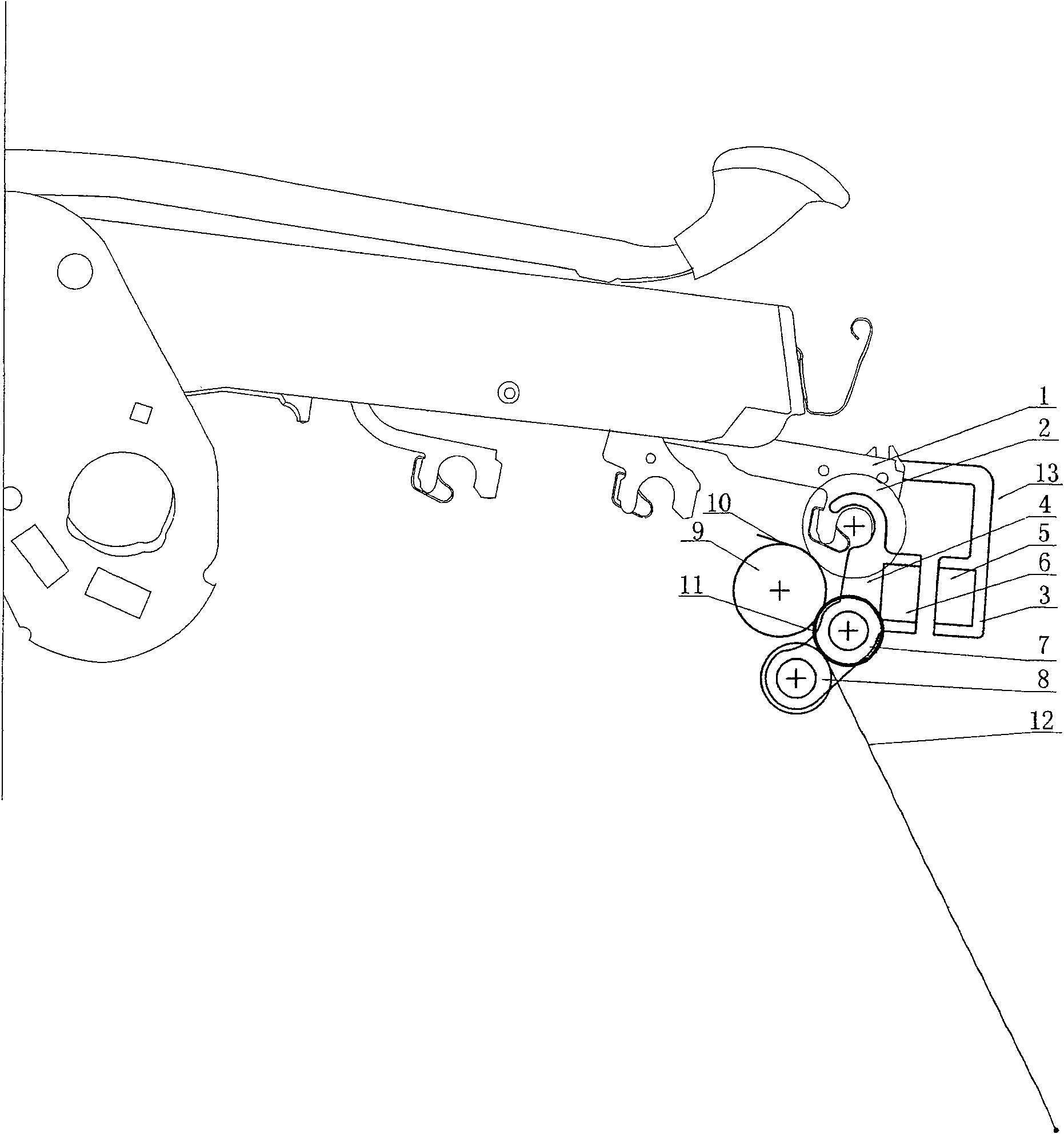

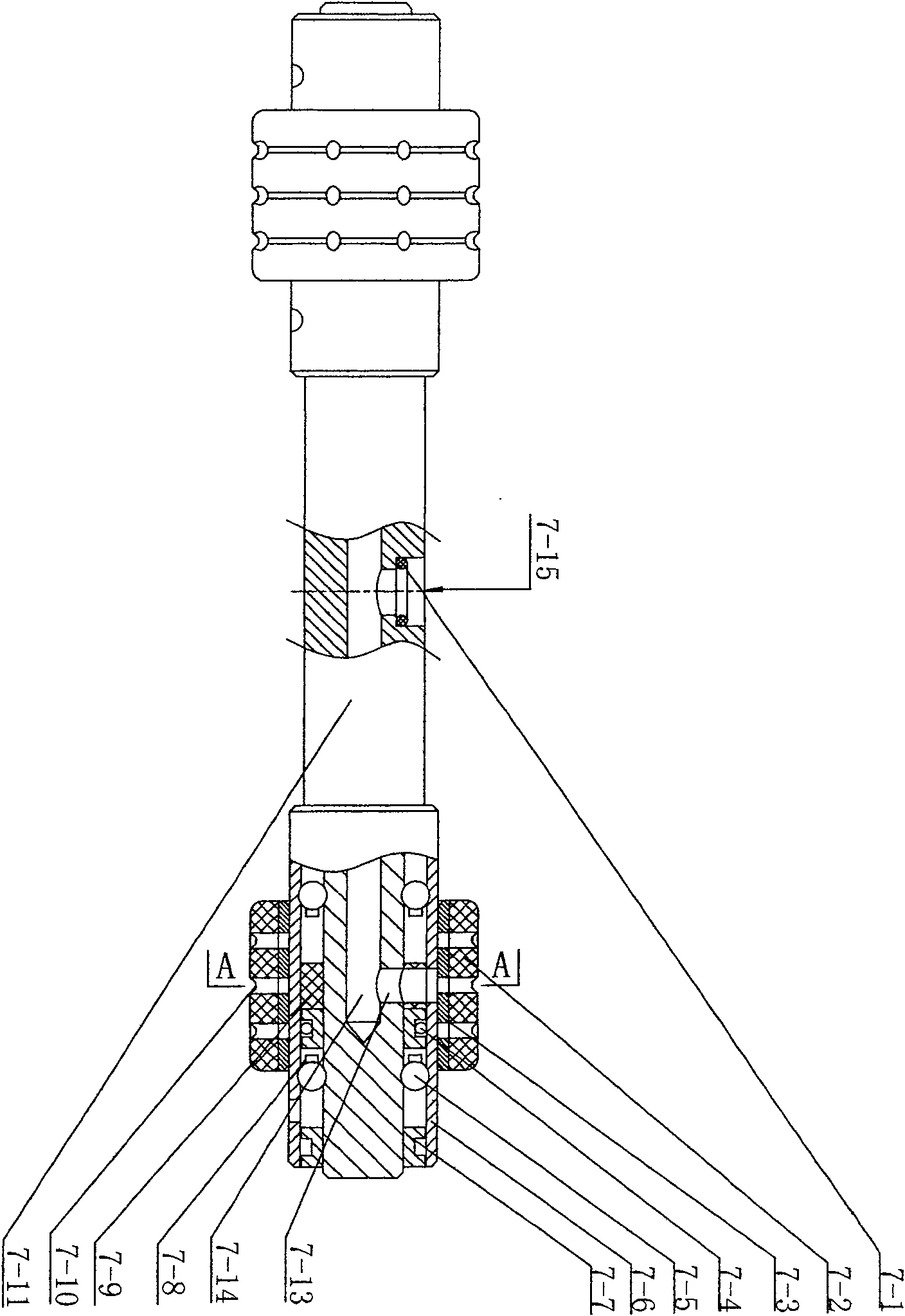

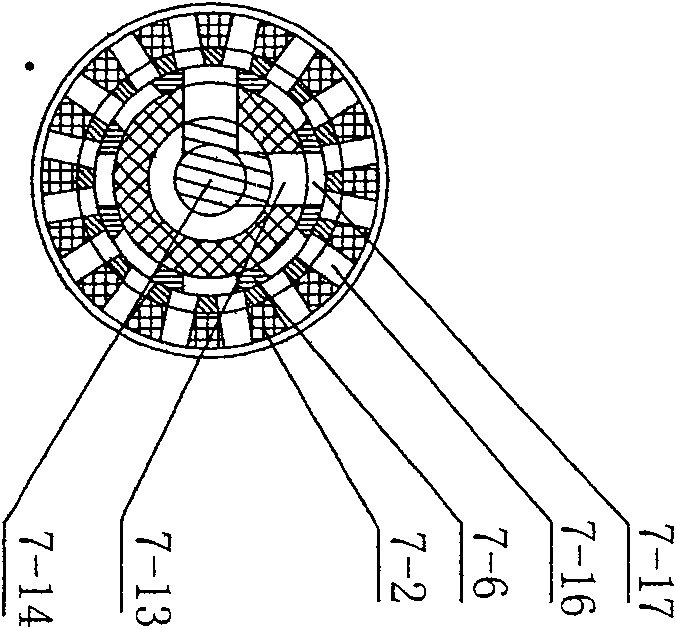

[0016] Such as figure 1 As shown, the lower top roller 2 is installed on the cradle 1 of the spinning frame, the bottom roller 9 is installed under the cradle 1 to closely match the lower top roller 2, the fixed seat 4 is connected to the lower top roller 2, and the upper rotating body 7 is installed on the fixed seat 4, and the lower rotating body 8 closely connected with the upper rotating body 7 is installed on the fixed seat 4, and the magnetic switch device 13 for controlling the fixed seat 4 is installed on the cradle 1.

[0017] Please reunite image 3 As shown, the magnetic switch device 13 is mainly composed of a group of magnets 5 installed on the magnetic switch base 3 and a group of magnets 6 installed on the fixed seat 4. During work, a group of magnets 6 moves to the right, and its S pole is aligned with a The S poles of the set of magnets 5 are opposite, and the N poles are opposite to the N poles of the set of magnets 5, thereby generating a repulsive force to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com