Compact spinning apparatus for spinning frame

A spinning frame, compact technology, applied in the direction of spinning machines, textiles, papermaking, drafting equipment, etc., can solve the problems that the yarn quality in the twisting triangle area cannot be eliminated, the speed of the compact spinning device is not synchronized, and the structure is complicated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

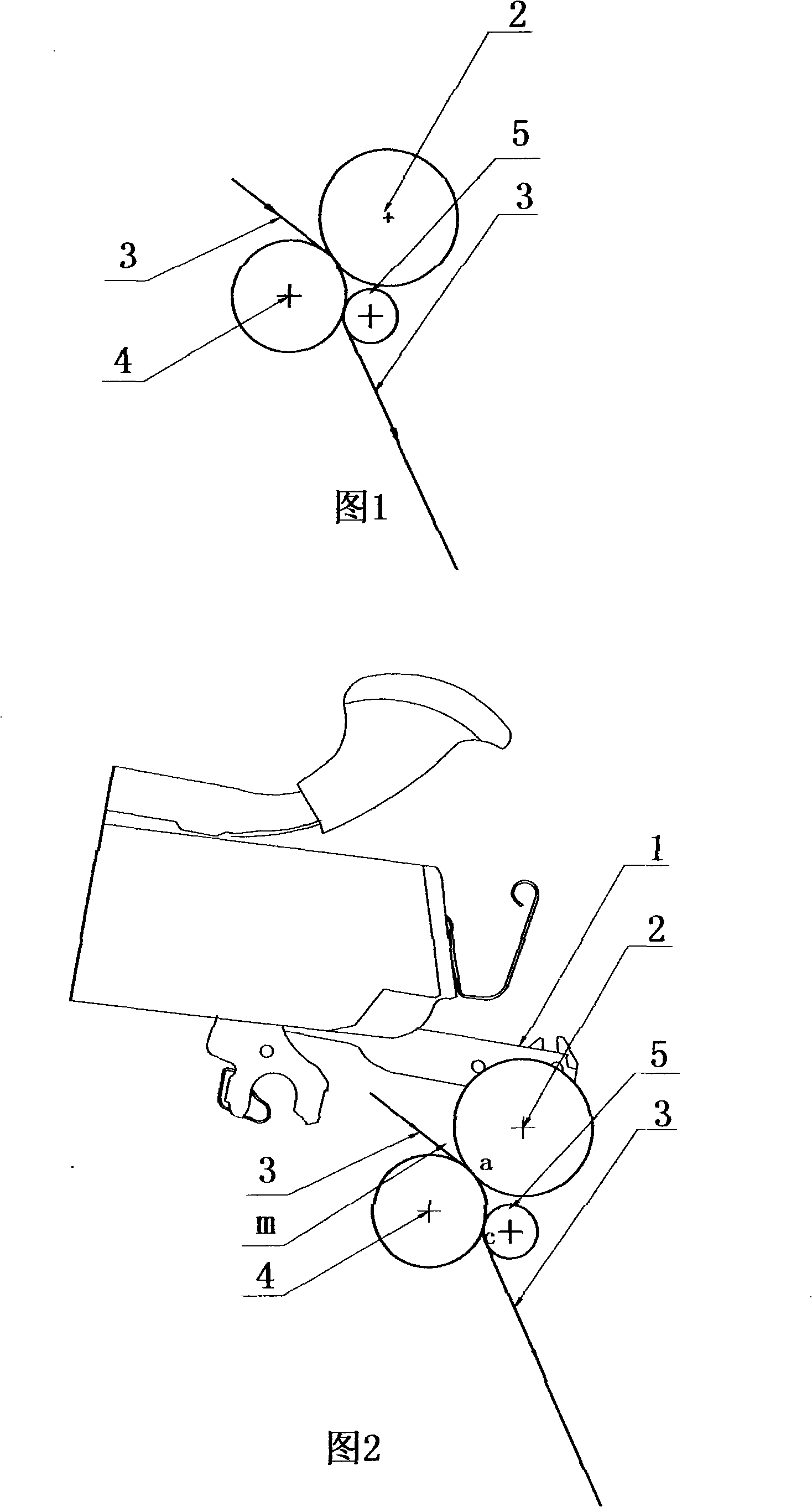

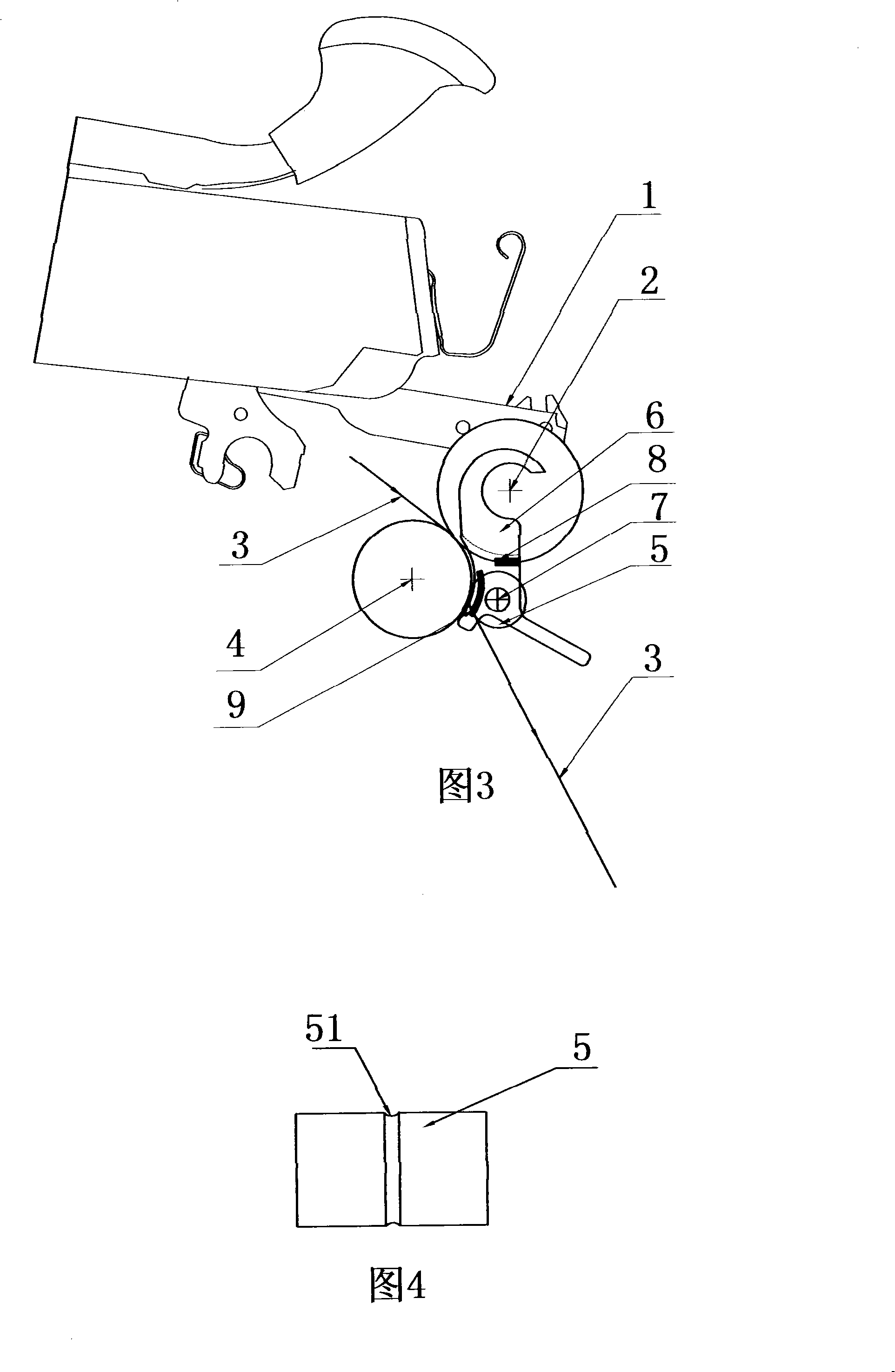

[0014] Such as figure 1 , figure 2 As shown, the front top roller 2 is installed on the cradle 1 of the spinning frame, and the front roller 4 is installed under the cradle 1 and pressed against the front top roller 2, and is formed between the front roller 4 and the front top roller 2. The contact area a of the pre-drafting device constitutes the drafting area m between the output end a of the drafting pressure roller composed of the front roller 4 and the front top roller 2; Pressing on the front roller 4, a contact area c is formed between the converging roller 5 and the bottom roller 4.

[0015] combine Figure 4 As shown, on the circumferential surface of the converging roller 5, there are several converging grooves 51 that are funnel-shaped from wide to narrow facing the direction of arrival of the yarn 3, so as to facilitate the converging of the yarn 3, and the converging roller 5 can pass through gravity and mechanical prestress. Or the magnetic attraction is pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com