Evaporating pan for vacuum smelting furnace

A technology of vacuum smelting and evaporator, which is applied in the field of vacuum smelting devices, can solve the problems of high manufacturing cost, difficult processing, and inability to implement, and achieve the effects of reduced manufacturing cost, convenient manufacturing, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

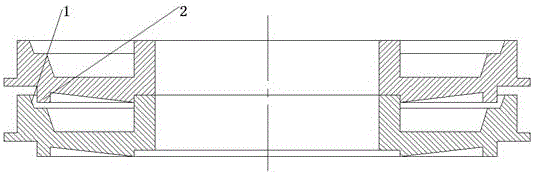

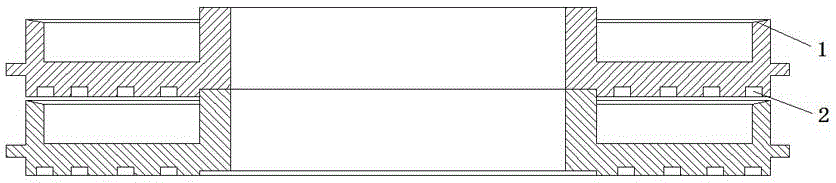

[0023] Such as figure 2 As shown, the evaporation pan for vacuum smelting furnace of the present invention is provided with at least one circle of grooves 2 on the bottom surface of the evaporation pan. The grooves 2 are arranged circularly on the bottom surface. Preferably, a circle of grooves is provided on the bottom surface of the evaporating pan corresponding to the outer edge of the liquid storage tank of the evaporating pan, so that the anti-splash effect is better. .

[0024] Four circles of grooves may be provided on the bottom surface of the evaporating tray. This works better.

[0025] The cross-sectional shape of the groove on the bottom surface of the evaporating tray is rectangular. It can also be arc-shaped.

[0026] As a further improvement, the liquid tank of the evaporator is inclined inwardly along the upper plane 1 . In this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com