Multilevel unhusked rice dedusting device for rice processing

A technology of rice processing and dust removal device, applied in the direction of removing smoke and dust, application, grain processing, etc., can solve the problems of low cleaning efficiency and poor cleaning effect, and achieve the effect of good dust removal effect and convenient cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

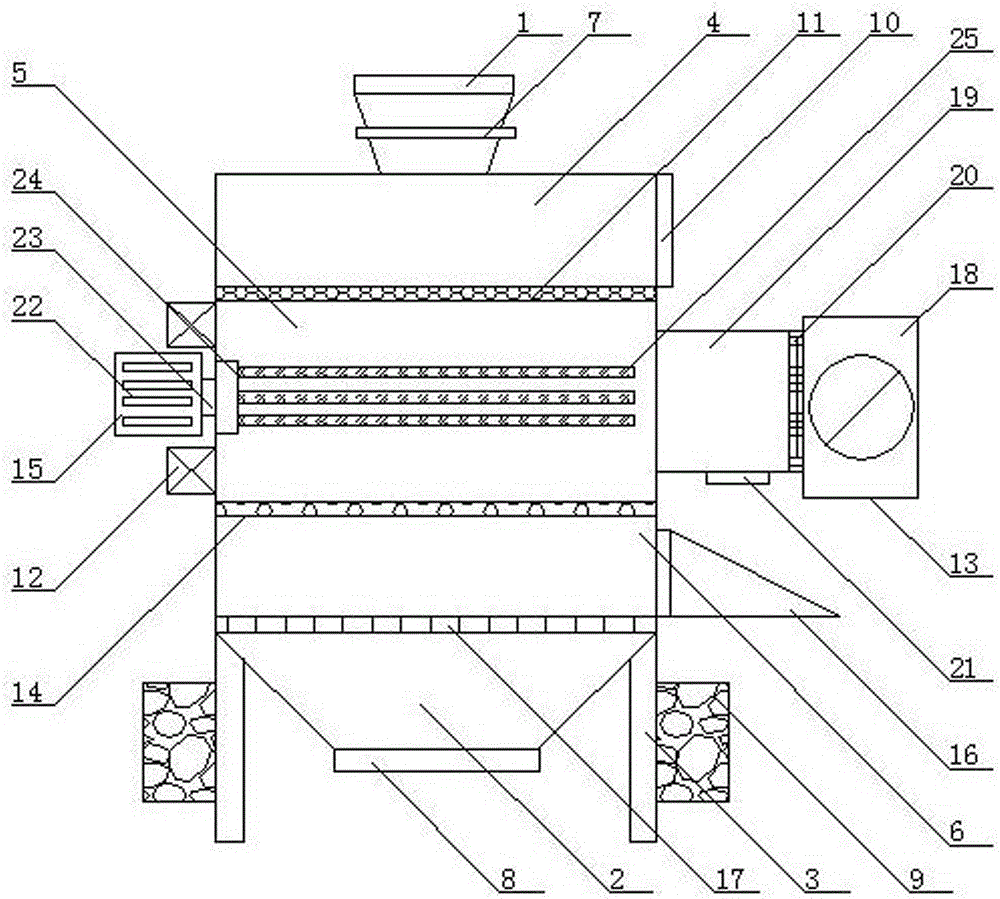

[0020] As shown in the figure, a multi-stage paddy dust removal device for rice processing includes a fuselage, a feed funnel 1 is installed in the middle of the top of the fuselage, a conical dust collection bin 2 is installed in the middle of the bottom of the fuselage, and the bottom of the fuselage is left and right. A support leg 3 is installed on each side; the first dust removal chamber 4, the second dust removal chamber 5, and the third dust removal chamber 6 are installed in sequence from top to bottom inside the fuselage.

[0021] A feeding regulating plate 7 is installed at the middle end of the feeding funnel 1 .

[0022] The ash outlet 8 is installed at the bottom end of the conical dust collection bin 2 .

[0023] The vibration mechanism 9 is installed at the middle end of the outer side of the support leg 3 .

[0024] The dust removal door 10 is installed on the right side of the first dust removal chamber 4, and the first stainless steel filter screen 11 is in...

Embodiment 2

[0030] Further, the aperture of the first stainless steel strainer 11 is greater than the aperture of the second stainless steel strainer 14, the aperture of the second stainless steel strainer 14 is greater than the aperture of the third stainless steel strainer 17, the third stainless steel strainer The aperture of 17 is less than the diameter of rice.

Embodiment 3

[0032] Further, nylon brush cloth is installed on the outside of the cleaning hair roller 25 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com