Method for recovering gold, antimony and lead from floatation tailings

A technology for flotation tailings and recovery of gold, which is applied in the field of comprehensive utilization of resources, can solve the problems of complex properties, large dosage of chemicals, and high cost of activated carbon drug removal, and achieve the effect of simple process and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

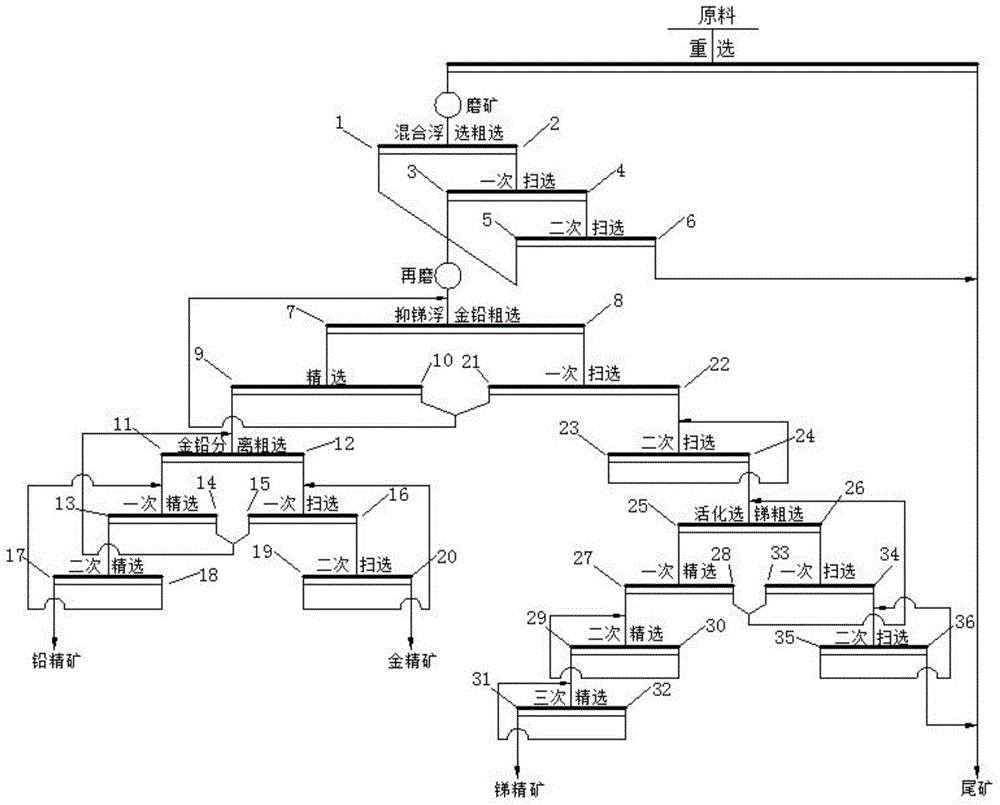

[0062] A flotation tailings contains 0.85g / t of gold, 0.34% of antimony, and 0.65% of lead. Process mineralogy analysis shows that pyrite is the main carrier mineral of gold, and the antimony minerals are mainly stibnite. The lead mineral is mainly galena.

[0063] according to figure 1 The shown process carries out the recovery of gold, antimony and lead, and the specific steps are as follows:

[0064] (1) re-election

[0065] The flotation tailings and water are adjusted to 20%, and the spiral chute is used to re-select the flotation tailings to obtain a gravity-selected concentrate with a yield of 56.25%.

[0066] (2) Grinding

[0067] Grinding the gravity-selected concentrate, the grinding concentration is 70%, and the grinding fineness is -0.074mm, accounting for 95%.

[0068] (3) Mixed flotation

[0069] (a) rough selection

[0070] Adjust the pulp concentration to 28%, add 400g / t of sodium carbonate and 250g / t of sodium hexametaphosphate, and stir for 7 minutes; t...

Embodiment 2

[0109] A certain flotation tailings contains 0.52g / t of gold, 0.51% of lead, and 0.23% of antimony. The results of technological mineralogy show that the main carrier minerals of gold are pyrite and arsenopyrite, and stibnite is antimony. The main form of occurrence, lead-bearing minerals mainly exist in the form of galena.

[0110] according to figure 1 The shown process carries out the recovery of gold, antimony and lead, and the specific steps are as follows:

[0111] (1) re-election

[0112] The flotation tailings and water are adjusted to 18%, and the spiral chute is used to re-select the flotation tailings to obtain a gravity-selected concentrate with a yield of 61.35%.

[0113] (2) Grinding

[0114] Grinding the gravity-selected concentrate, the grinding concentration is 60%, and the grinding fineness is -0.074mm, accounting for 85%.

[0115] (3) Mixed flotation

[0116] (a) rough selection

[0117] Adjust the pulp concentration to 20%, add sodium carbonate 200g / t...

Embodiment 3

[0156] A flotation tailings contains 0.49g / t of gold, 0.60% of lead, and 0.28% of antimony. The research results of technological mineralogy show that the main carrier mineral of gold is pyrite, and stibnite is the main occurrence form of antimony. Lead-bearing minerals mainly exist in the form of galena.

[0157] according to figure 1 The shown process carries out the recovery of gold, antimony and lead, and the specific steps are as follows:

[0158] (1) re-election

[0159] The flotation tailings and water are adjusted to 17.5%, and the spiral chute is used to re-select the flotation tailings to obtain a gravity-selected concentrate with a yield of 58.10%.

[0160] (2) Grinding

[0161] Grinding the gravity-selected concentrate, the grinding concentration is 64%, and the grinding fineness is -0.074mm, accounting for 88%.

[0162] (3) Mixed flotation

[0163] (a) rough selection

[0164] Adjust the pulp concentration to 24%, add sodium carbonate 300g / t and sodium hexam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com